The component-related risks faced by SMT assembly plants, and how early BOM review and stable sourcing can improve the reliability of large-scale production.

I. Background: Real Challenges Faced by SMT Assembly Factories During Mass Production

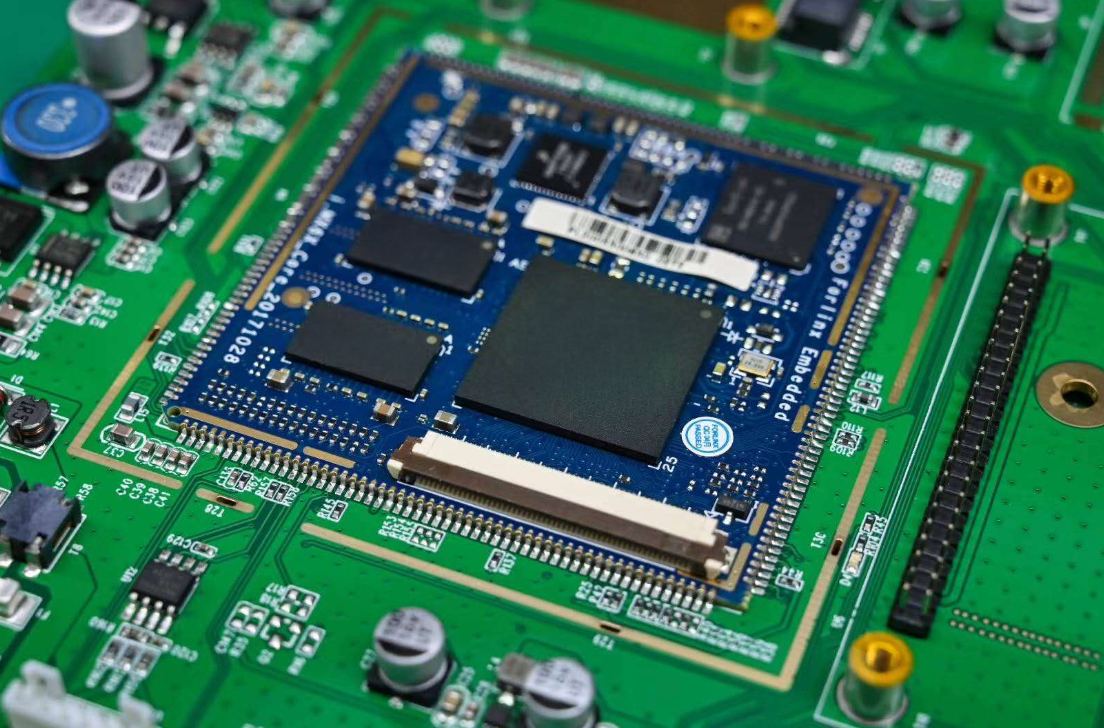

In the electronics manufacturing chain, SMT assembly factories (EMS providers) play a critical role in transitioning products from prototype to mass production. A single SMT line often supports multiple customer projects across industrial control, communication equipment, and consumer electronics.

Beyond placement accuracy and yield, SMT factories must deal with frequent line changes, BOM revisions, compressed delivery schedules, and unstable component supply.

II. Field Symptoms: Assembly Looks Fine, Failures Appear After Shipment

During SMT assembly and outgoing inspection, products usually appear normal, with good solder joints, passed AOI inspection, and successful ICT or functional testing.

However, after deployment at customer sites, issues begin to appear, such as unstable power-up, intermittent module failures, or increasing failure rates after long-term operation.

III. Initial Misjudgment: Issues Are Often Attributed to Assembly Process

When failures are traced back to the SMT factory, attention is usually focused on soldering profiles, paste printing quality, or component placement accuracy.

As a result, process adjustments or rework are performed, but post-project analysis often shows that assembly quality was not the root cause.

IV. Root Cause: Component Selection and Supply Chain Instability

Further investigation reveals that the real issues often originate at the component level, including parameter variations between batches, unverified substitutes, or components sourced from mixed channels.

These risks are invisible during SMT assembly but become amplified during real-world operation.

V. Practical Solutions: How SMT Factories Reduce Component-Related Risks

In mature SMT/EMS projects, risks are reduced through early BOM reviews, unified sourcing strategies, and close collaboration with reliable component distributors to ensure batch consistency and long-term availability.

VI. Results: From Reactive Rework to Proactive Risk Control

With improved component control, SMT factories typically achieve lower rework rates, fewer customer complaints, and more predictable delivery performance.

VII. SMT Assembly Plant Precautions

In today’s manufacturing environment, SMT factories are no longer just assembly providers but critical partners in project success. Early identification of component risks and stable sourcing directly impact long-term customer relationships.