An in-depth analysis of component-related risks faced by PCB assembly factories and how upstream control improves delivery reliability.

I. Background: The Real Role of PCB Assembly Factories in Project Delivery

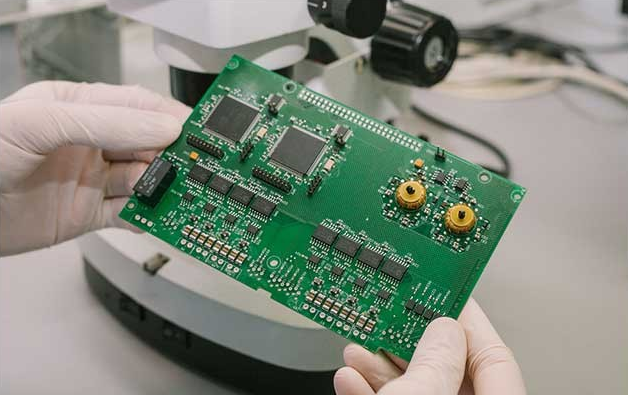

In the electronics manufacturing ecosystem, PCB assembly factories (PCBA / EMS providers) are responsible for the complete process—from SMT placement and through-hole assembly to board-level testing and final delivery.

Unlike pure SMT services, PCB assembly factories are accountable for overall board functionality, stability, and consistency.

As a result, when field failures occur, PCB assembly factories are often the first party held accountable.

II. Field Symptoms: Boards Pass Assembly but Fail at Customer Sites

During PCB assembly, boards typically show no visible issues:

SMT and THT soldering appear normal

AOI and X-Ray inspections pass

Short functional tests are successful

However, after deployment in customer equipment, issues emerge gradually, such as unstable power-up, intermittent module failures, or increased failure rates during long-term operation.

III. Initial Misjudgment: Issues Attributed to Process or Testing

When failures are traced back to the PCB assembly factory, common assumptions include soldering defects, insufficient test coverage, or inadequate burn-in time.

As a result, factories may increase testing or rework, yet failures continue to recur.

IV. Root Cause: Lack of Component Consistency and Traceability

Post-project analysis often reveals that the real issue lies in component inconsistency, such as parameter variation between batches, unverified substitutes, mixed sourcing channels, or the use of consumer-grade parts in industrial designs.

These risks are nearly impossible to detect during assembly or short tests but become amplified during real-world operation.

V. Practical Solutions: How PCB Assembly Factories Control Risks Upstream

Mature PCB assembly plants typically optimize in the following aspects:

Pre-screening of key components: Highlight power supply, interface, protection, and communication ICs to confirm their lifecycle and supply stability, and avoid using NRND/part numbers from unknown sources.

Unified material sourcing and batch management: Avoid using materials from different sources for the same project, record batch information, and facilitate problem tracing.

Collaborate with reliable component distributors: Provide on-demand stock and delivery guarantees, support BOM matching and alternative suggestions, and reduce systemic risks associated with temporary component changes.

VI. Results: Improved Delivery Capability and Customer Trust

With proactive component control, PCB assembly factories achieve lower rework rates, fewer customer complaints, and more predictable delivery performance.

This improvement directly affects long-term customer partnerships, not just product quality.

VII. Practical Advice for PCB Assembly Factories

In today’s competitive manufacturing environment, PCB assembly factories are no longer just executors but key partners in project success.

Controlling component risk upfront is far more valuable than reactive rework.