A real industrial case study explaining why power boards fail due to transient overcurrent and how real-time current monitoring prevents repeated damage.

I. Project Background: DC/DC Power Board in Industrial Automation Equipment

This project involves a DC/DC power board used in an industrial automation control system, converting a 24V industrial supply into 5V and 3.3V rails for the MCU, communication modules, and sensor interfaces.

The equipment operates 24/7 in the field, with frequent load variations depending on operating conditions.

II. Field Symptoms: Random Board Failures That Are Hard to Reproduce

After 1–3 weeks of field operation, some units began experiencing power board failures, including:

Overheated and damaged input-side MOSFETs

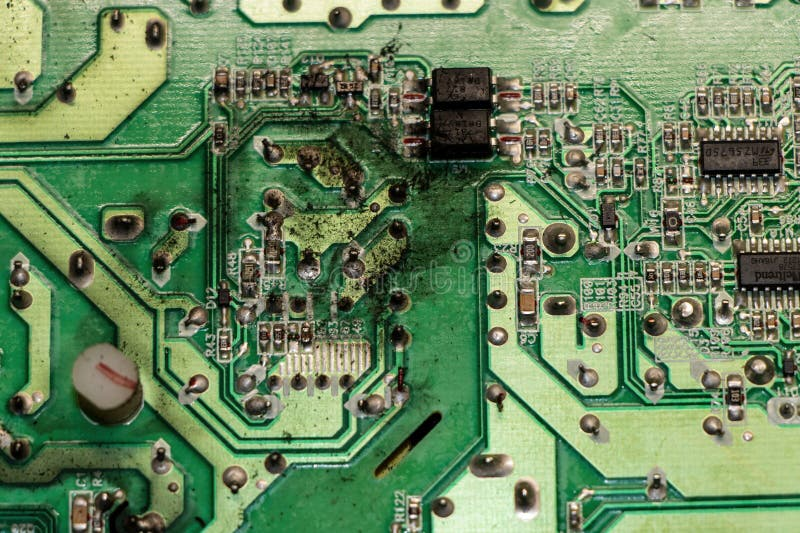

Localized PCB burn marks

No system warnings or logged faults before failure

The failures were random across units, making them difficult to reproduce during short lab tests.

III. Initial Troubleshooting and Misjudgment

At first, the engineering team focused on power component ratings and tried:

Using higher-rated MOSFETs

Improving heat dissipation

Adjusting DC/DC switching frequency

However, these changes increased cost without eliminating failures.

IV. Root Cause Analysis: The System Was Blind to Transient Overcurrent

After further analysis of the on-site data, the true cause of the problem gradually became clear:

Multiple modules started simultaneously upon power-on or reset.

The load changed rapidly within a short period.

The on-site industrial power supply experienced transient fluctuations.

These factors combined to cause repeated short-term overcurrent surges to the power devices.

Because the system relied solely on fuses and over-temperature protection:

The transient overcurrent protection was not triggered.

The MCU could not record the anomaly.

The problem only manifested as board burn-out after a long period of accumulation.

V. Practical Solution: Adding Real-Time Current Monitoring

Instead of over-sizing components, the final solution added high-side current monitoring on the DC/DC output path, allowing:

Real-time current and power measurement

Detection of abnormal startup currents

Controlled power sequencing or current limiting

This shifted the system from passive endurance to proactive protection.

VI. Results: Significant Improvement in Reliability

After implementation and mass production:

No further power board failures were reported

Power component temperatures dropped significantly

The system passed long-term field validation

Most importantly, power behavior became visible and manageable.

VII. Practical Takeaways for Engineers and Buyers

In industrial equipment, power board burnout is often not a problem of a single component, but rather a result of the system lacking real-time current sensing capabilities.

For projects involving:

Industrial power supplies

Equipment operating for extended periods

Projects with high reliability requirements

Introducing current monitoring should no longer be considered an "optional optimization," but rather an integral part of the fundamental design.