Comprehensive guide to testing AC/DC input protection networks using MOV varistors, X2 capacitors, and NTC thermistors under IEC surge and inrush conditions.

Testing surge and inrush performance is essential to validate the real-world reliability of MOV varistors, X2 capacitors, and NTC thermistors in AC/DC input networks.

These tests ensure compliance with IEC and UL standards while confirming component endurance under repetitive stress.

IEC 61000-4-5: Surge Immunity Test

IEC 61000-4-11: Voltage Dip and Interruption Test

UL 1449: Varistor Certification Standard

IEC 60384-14: X2 Capacitor Withstand Voltage Standard

|

Equipment type |

Model Example |

Use |

|

Surge Generator |

EM Test NX5 |

Simulated ±2kV differential mode surge |

|

Oscilloscope |

Tektronix MDO3024 |

Measuring residual voltage waveform |

|

Current clamp |

Fluke i410 |

Measuring peak current upon power-on |

|

thermal imager |

Flir E8 |

Temperature rise of monitoring devices |

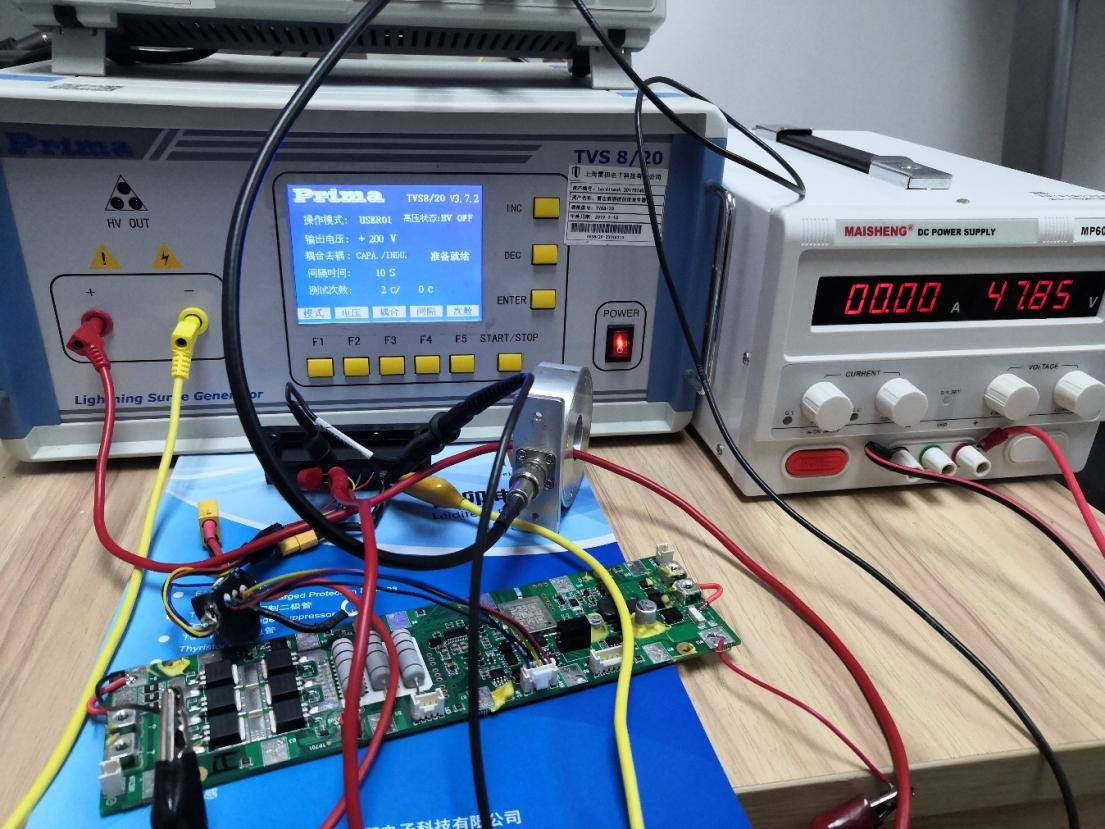

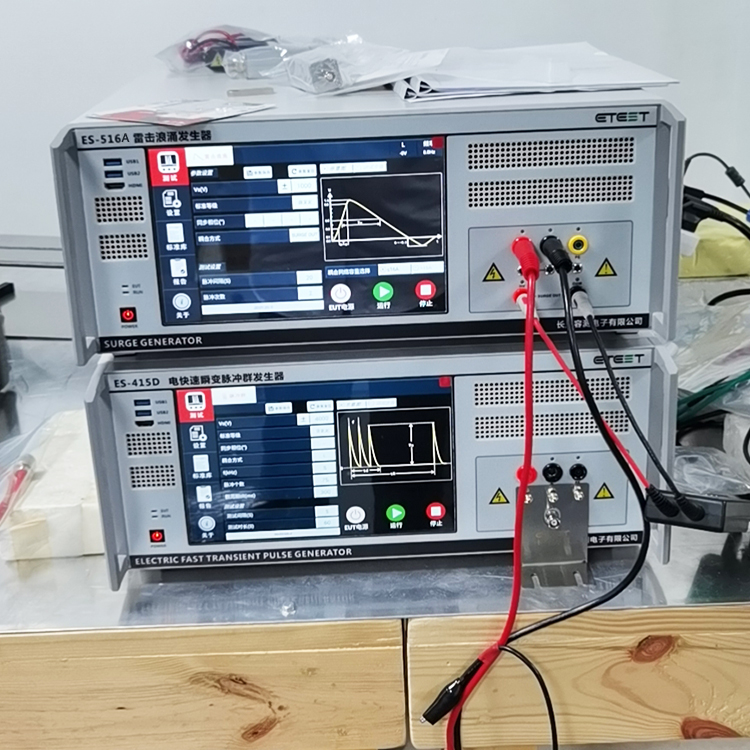

Equipment includes: Surge generator (±2kV), high-bandwidth oscilloscope, current clamp, and infrared thermal camera to capture transient response and thermal behavior.

AC Input ── Fuse ── MOV ──┬── Bridge ── DC Bus

│

X2

│

NTC ──► Load

Circuit Explanation:

The MOV absorbs high-energy surge spikes, X2 filters differential-mode noise, and NTC limits the inrush current during cold startup.

Together, they ensure full input-stage protection for AC/DC converters.

Step 1: Surge Test

Test Conditions: ±2kV differential mode surge (1.2/50µs waveform)

MOV Model: JARON 10D471K

Test Results: Residual voltage 530V, clamping stable, no performance degradation after 20 repetitions.

Step 2: Inrush Current Test

Voltage: AC 230V

Capacitor: 330µF electrolytic capacitor

NTC: JARON MF72-10D15Ω

Cold start peak current decreased from 48A to 8.5A, achieving a suppression rate of 82%.

Step 3: Voltage Dip Test

50% voltage held for 10ms → recovery

X2 capacitors: 0.22µF/275VAC

Result: Output waveform recovers smoothly with no oscillation; differential mode noise decreases by 12dB.

|

Project |

Test metrics |

Result |

|

Surge residual pressure |

<550V |

Pass |

|

Peak current |

<10A |

Pass |

|

EMI suppression |

-12 dB improvement |

Pass |

|

thermal stability |

≤65°C |

Pass |

|

Response time |

<25ns |

Pass |

Summary:

All tests passed comfortably, with low residual voltage, fast transient response, and stable thermal performance under prolonged cycles.

Thermal imaging results show that after 1 hour of continuous operation at AC 230V:

The MOV surface temperature stabilized at 58°C;

The NTC peak temperature rise was 63°C, with a recovery time of 45 seconds;

The X2 capacitor showed almost no significant temperature rise.

Verified through actual testing:

Surge suppression effect is significant, with residual voltage reduced by 45%;

Power-on surge current is controlled within 5 times the rated current;

EMI suppression performance is improved by 12dB;

Key components exhibit low temperature rise, fast response, and high stability.

This solution can be directly applied to:

AC/DC switching power supplies (SMPS);

Industrial control power supplies;

LED driver power supplies;

Inverter and charging pile modules.

JARON's MOV + X2 + NTC three-in-one protection solution, verified by the IEC 61000 series standards, demonstrates its superior performance in surge absorption, EMI suppression, and current limiting protection.

This solution not only simplifies circuit design but also provides OEM/ODM manufacturers with high reliability and mass production consistency support.

Surge Test | Inrush Verification | MOV+X2+NTC | Power Input Protection