Learn how to select MOV varistors and X2 safety capacitors for AC/DC input protection according to IEC and UL standards, improving surge suppression and EMI filtering.

1. Introduction

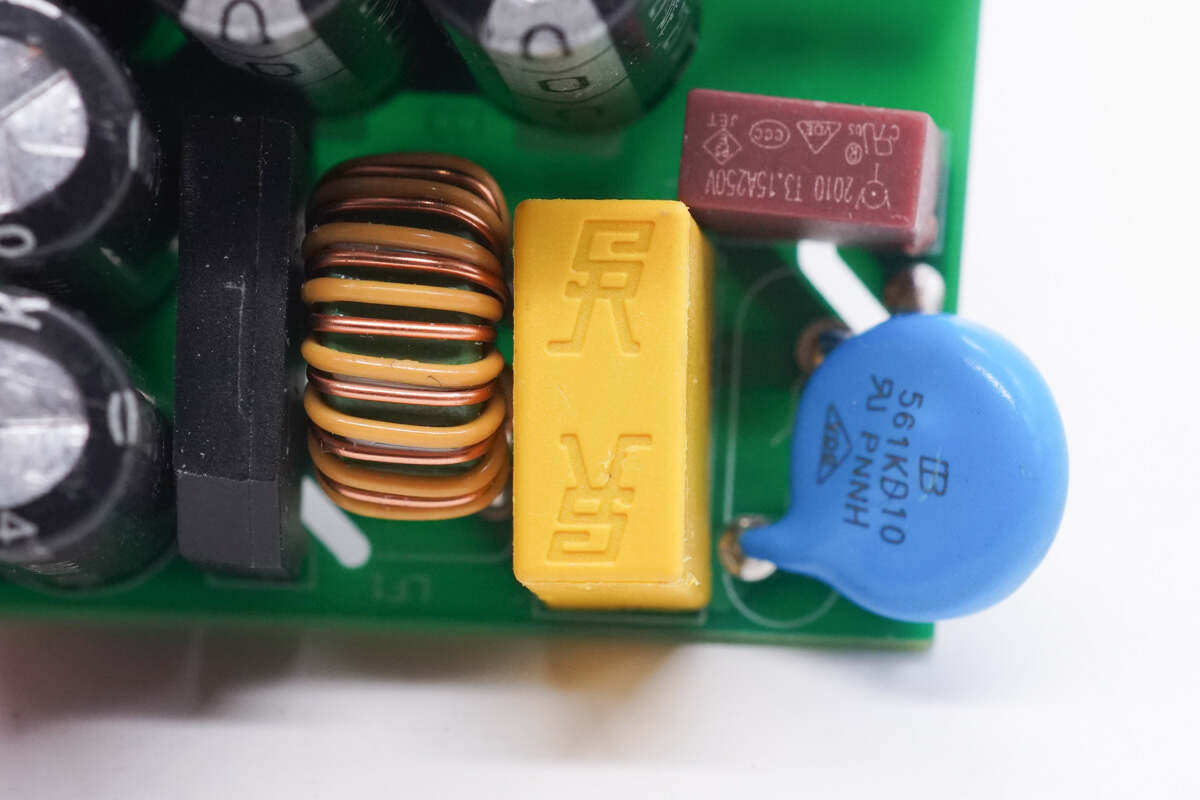

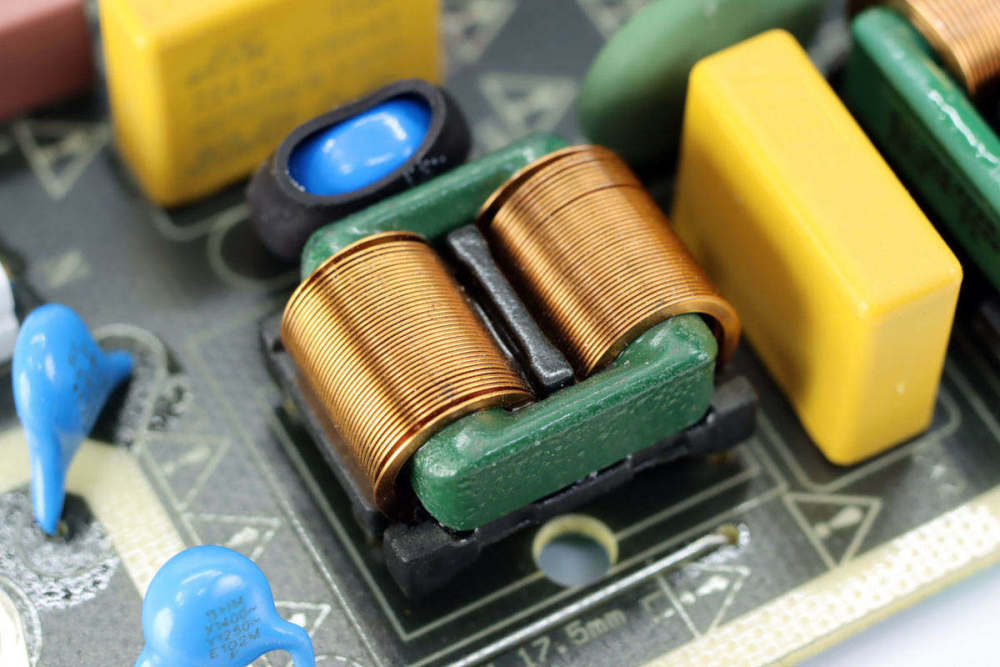

In AC/DC power input protection, MOV varistors and X2 safety capacitors form the foundation of surge suppression and noise filtering.

The right combination determines the converter’s long-term reliability, EMC performance, and compliance with international safety standards.

2. Functional Roles of MOV and X2 Capacitor

MOV Varistor:

Acts as a transient voltage suppressor. It conducts within nanoseconds to divert surge energy away from sensitive circuitry.

JARON 10D471K provides 470V clamping voltage and 120J surge energy capacity, ideal for 230VAC systems.

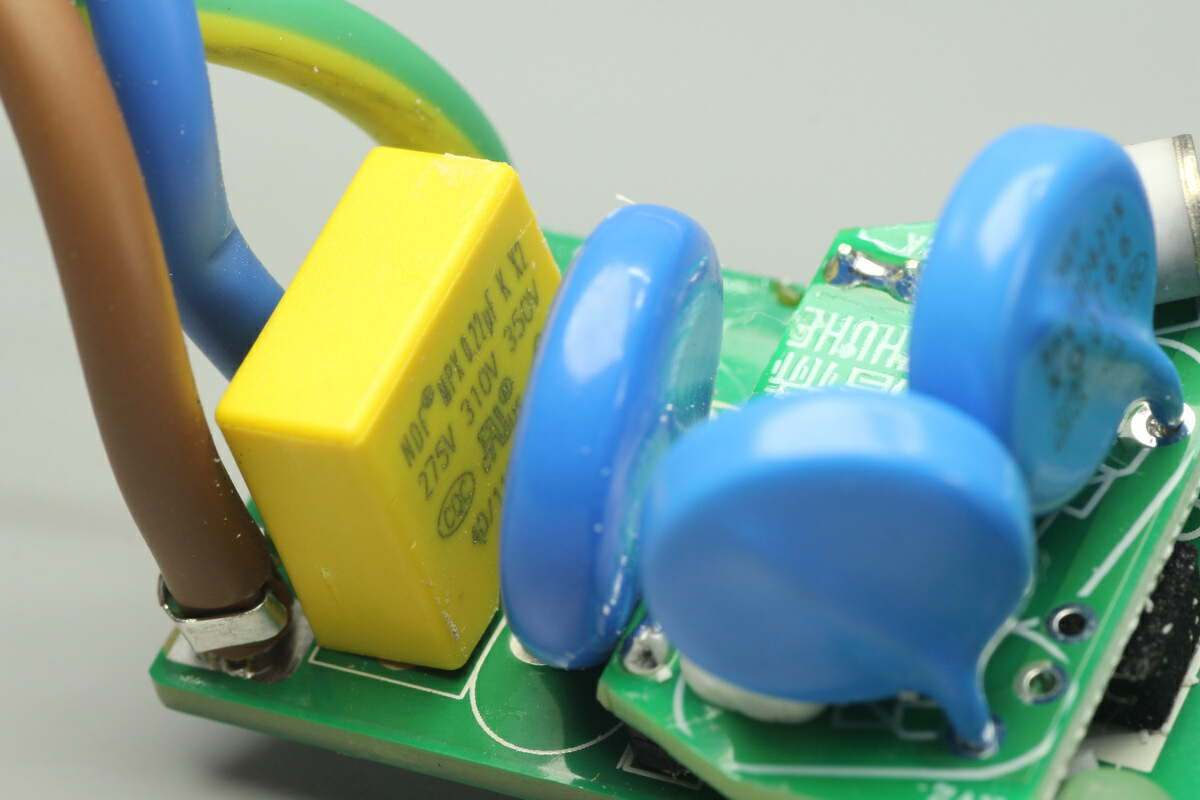

X2 Capacitors – Differential Mode Noise Filtering

Installed between L–N pins, absorbs power line interference signals;

Self-healing and flame-retardant properties, meeting IEC 60384-14;

Recommended model: JARON X2-MKP series, capacitance range 0.1–0.47µF, rated voltage 275/310VAC.

3. Standardized Selection Method

The correct selection process should consider voltage level, energy matching, and capacitor discharge characteristics simultaneously. The following are the recommended steps:

Step 1: Determine the rated voltage of the power supply

|

Voltage Platform |

Recommended MOV voltage |

Recommended x2 capacitance |

|

110VAC |

250–275V |

0.1–0.22 µF |

|

220–230VAC |

470V |

0.22–0.47 µF |

|

277VAC Industrial System |

560V |

0.33–0.47 µF |

Step 2: Matching Energy Absorption and Discharge Time

MOV Energy ≥ X2 Capacitor Discharge Energy × 1.2;

MOV Response Time should ≤ X2 Capacitor Discharge Time;

If the input surge environment is severe (such as industrial scenarios), it is recommended to connect two MOVs in parallel to improve energy margin.

4. Testing and Comparative Data

Under the same power supply conditions, a comparison is made between the traditional RC filtering scheme and the MOV + X2 combination scheme:

|

Test Project |

RC solution |

MOV+X2 solution |

Improvement range |

|

Peak residual pressure |

890V |

530V |

↓40% |

|

EMI interference |

−26 dBµV |

−42 dBµV |

↓16 dB |

|

Verification cycle |

4 weeks |

1.5 weeks |

↓62% |

|

Component temperature rise |

85°C |

61°C |

↓28% |

Testing shows a 40% reduction in residual voltage, 16dB EMI improvement, and 28% lower thermal rise, proving the MOV+X2 combination superior to RC-based designs.

5. Environmental and Safety Compliance

|

Standard Number |

Test Project |

Applicable Devices |

|

IEC 61000-4-5 |

Surge immunity |

MOV varistor |

|

IEC 60384-14 |

Safety capacitor requirements |

X2 capacitors |

|

UL 1449 |

Overvoltage protection standard |

MOV |

|

EN 60950 / 62368 |

Power safety certification |

MOV + X2 combination |

All JARON products comply with RoHS, REACH, UL/TUV/CQC certification requirements and can be directly applied to switching power supplies, adapters, inverters, and home appliance control systems.

6. Design Guidelines

The MOV should be placed close to the fuse input terminal to shorten the energy absorption path;

The X2 capacitor should be close to the rectifier bridge input to form a low-impedance loop;

To improve safety compliance, a discharge resistor (≥1MΩ) can be connected in parallel;

In high surge environments (lightning strike areas/factory power distribution terminals), a thermal protection fuse or varistor module can be added.

7. Application Scenarios

The MOV+X2 combination is ideal for industrial power modules, LED drivers, home appliance controllers, and EV charging systems, providing stable and reliable surge and EMI protection.

8. Conclusion

JARON's MOV + X2 standardized combination solution achieves the optimal balance of safety, stability, and low loss in AC/DC input protection.

It meets IEC/UL international standards, is compatible with multiple voltage platforms, and provides global OEMs/ODMs with a highly consistent and easily mass-producible power protection solution.

MOV+X2 Combination | AC/DC Input Protection | Surge Filter Design | Safety Capacitor Selection