Learn how Jaron’s JRN/JRT Series combines EMI filtering and surge protection into one device, reducing BOM, improving ISO 7637-2 compliance, and optimizing automotive DC motor performance.

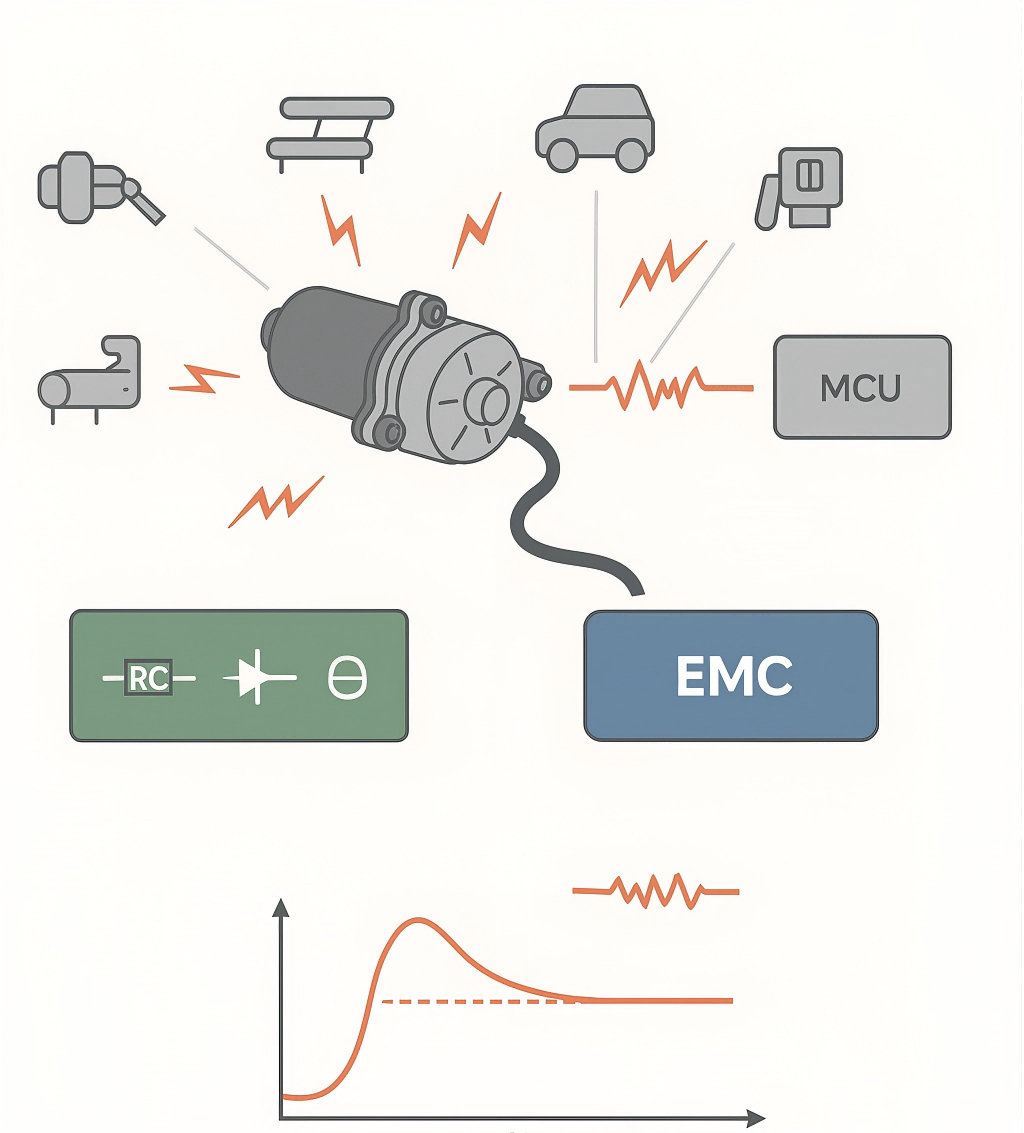

In modern vehicles, more than twenty DC motors work simultaneously—for windows, wipers, tailgates, seat adjusters, fuel pumps, and HVAC fans. Each motor generates electromagnetic interference (EMI) and transient surges that travel through harnesses and disturb control modules. This noise can trigger communication errors or permanent damage if not properly filtered.

Traditional protection networks use RC snubbers, TVS diodes, and EMI capacitors. However, this multi-component approach leads to high BOM cost, large board space, poor consistency, and longer validation cycles. As carmakers move toward modular and compact designs, integrated EMC protection is becoming essential.

The JRN/JRT series from Jaron uses a multilayer ceramic-MOV composite structure that provides EMI filtering, voltage clamping, and energy absorption in a single device. This integration replaces up to three discrete components, simplifying the design and improving overall stability.

|

Parameter items |

Numerical range |

Engineering significance |

|

Rated voltage |

16V – 56V DC |

Suitable for 12V/24V/48V platforms |

|

Response time |

<25 ns |

Rapidly suppress surge spikes |

|

Capacity range |

0.1 – 4.7 µF |

Simultaneously filters out high-frequency and low-frequency interference. |

|

Clamping voltage |

As low as 1.4×VDC |

Improve system security margin |

|

Energy absorption |

800A–1200A(8µs) |

Meets ISO Level 3–4 requirements |

Each device can suppress surges up to 1200A with sub-25ns response time, while providing up to 4.7µF capacitance for broadband EMI filtering. It meets ISO 7637-2 and ISO 16750-2 standards, ideal for Tier-1 and Tier-2 automotive suppliers.

This hybrid design ensures smooth transition from high impedance to clamping state within nanoseconds, avoiding voltage overshoot.

Case A: Chengdu Huachuan Denso (Windshield Wiper/Window Lift System)

Results Comparison:

Case B: Wenzhou Shenghuabo (Seat Motor/Tailgate System)

|

Comparison Dimensions |

Traditional RC+TVS |

JRN/JRT Integration Solution |

Improvement rate |

|

Number of devices |

3–4 piece |

1 piece |

↓70% |

|

Cost control |

high |

Low |

↓40% |

|

Verification cycle |

2-3 rounds |

Round 1 |

↓60% |

|

Space usage |

100% |

45% |

↓55% |

|

residual pressure level |

70–80V |

40–50V |

↓35% |

The integrated solution reduces component count by up to 70%, shortens validation time, and improves reliability. It simplifies design while maintaining robust compliance with ISO and CISPR standards.

With the upgrading of ISO standards and the standardization of OEM platforms, integrated protection is becoming a trend in automotive electronics.

The design concept of the JRN/JRT series is being widely adopted by the Tier-1 supply chain for applications such as BCMs, motor control modules, and smart seat systems. Within the next three years, integrated protection solutions are expected to replace more than 70% of traditional RC network designs.

The JRN/JRT series delivers three functions in one device—EMI suppression, surge clamping, and energy absorption.

With sub-25ns response and µF-level capacitance, it simplifies circuit design, reduces BOM cost, and guarantees compliance with ISO automotive standards.

For global Tier-1 and Tier-2 suppliers, this integration marks a key step toward smarter, faster, and safer automotive electronics.

Automotive EMC | EMI+Surge Integrated | JRN Series | DC Motor Protection | ISO 7637-2