This article starts from the control architecture of industrial robots and explores the key role and integration trends of Schottky diodes in power rectification, regenerative protection, and signal interference.

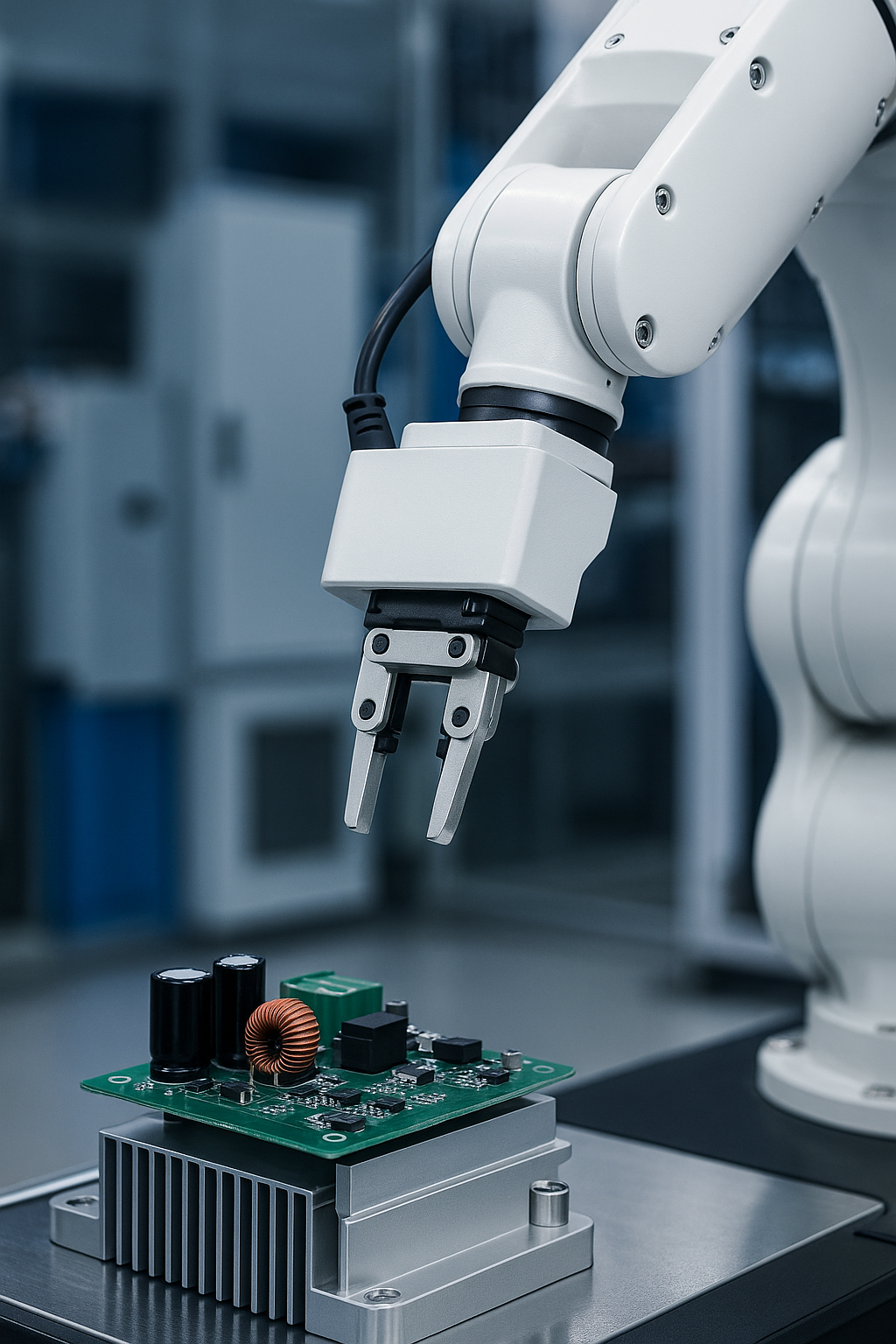

I. Building the Control Core of Industrial Robots

A typical six-axis robotic system comprises servo power, motor drivers, feedback loops, and protective circuits. Given the demand for both high-speed response and energy efficiency, Schottky diodes are integral to the system.

II. Efficiency Backbone for High-Speed Drives

With forward drops of just 0.2–0.4V, Schottky diodes reduce thermal losses in SMPS circuits. They are widely used in servo power supplies of robots to improve drive efficiency and power stability.

III. Reverse Protection and Regenerative Current Management

During motor braking or reversal, regenerative currents occur. Schottky diodes, acting as freewheeling paths, conduct quickly to discharge energy and protect MOSFETs and MCUs from voltage spikes.

IV. EMI Suppression and Signal Shaping

Industrial robots involve numerous high-frequency signals. With their fast switching and short recovery time, Schottky diodes suppress EMI and enhance signal clarity, especially in PWM or encoder circuits.

V. Integration and Modularization Trends

Modern robotic controllers are evolving toward SoC modularity. Schottky diodes are being embedded into power SoCs, power modules, and thermal baseplates for streamlined integration.

Bidirectional Schottky configurations are also emerging, enabling energy discharge in both directions, which enhances flexible protection in high-speed load interfaces.

Schottky diode | industrial robot | control system | freewheeling protection