How Diodes Control Current Flow to Protect Circuit Integrity

Understanding diode functionality and unidirectional current flow mechanisms

Think of diodes as electrical one way street signs for electrons. They let current pass through only when it goes from the anode side to the cathode side. Why does this happen? Well, inside every diode there's something called a P-N junction. This creates what amounts to a built in wall that stops electricity from flowing backwards. When working with direct current systems, this feature actually saves equipment from getting fried if someone accidentally connects things backwards. Some studies indicate that when engineers properly install these components, they prevent those kinds of problems around 89 percent of the time simply because the diode blocks any unwanted backflow of electricity that could otherwise cause serious issues down the line.

Forward-bias and reverse-bias operation: How diodes regulate current direction

When forward-biased—typically above 0.7V for silicon diodes—the P-N junction’s resistance drops sharply, enabling efficient conduction. Under reverse bias, the junction resists current flow, limiting leakage to microamp levels. Proper biasing enhances circuit efficiency by 40—60% in power regulation applications, according to PCB design analyses.

Semiconductor fundamentals: P-N junctions explained

The P-N junction is formed by joining p-type (electron-deficient) and n-type (electron-rich) semiconductor materials. At the interface, a depletion zone develops that acts as:

- A voltage-controlled gate for electron flow

- A built-in electric field (approximately 0.3V in germanium, 0.7V in silicon)

- A self-repairing barrier that blocks reverse current under normal conditions

Diode current flow characteristics under varying voltage conditions

Diodes operate across three key regions:

- Cut-off region (<0.5V): Negligible current flows

- Linear region (0.5—0.7V): Current increases exponentially with voltage

- Saturation region (>0.7V): Stable conduction occurs with dynamic resistance around 1Ω

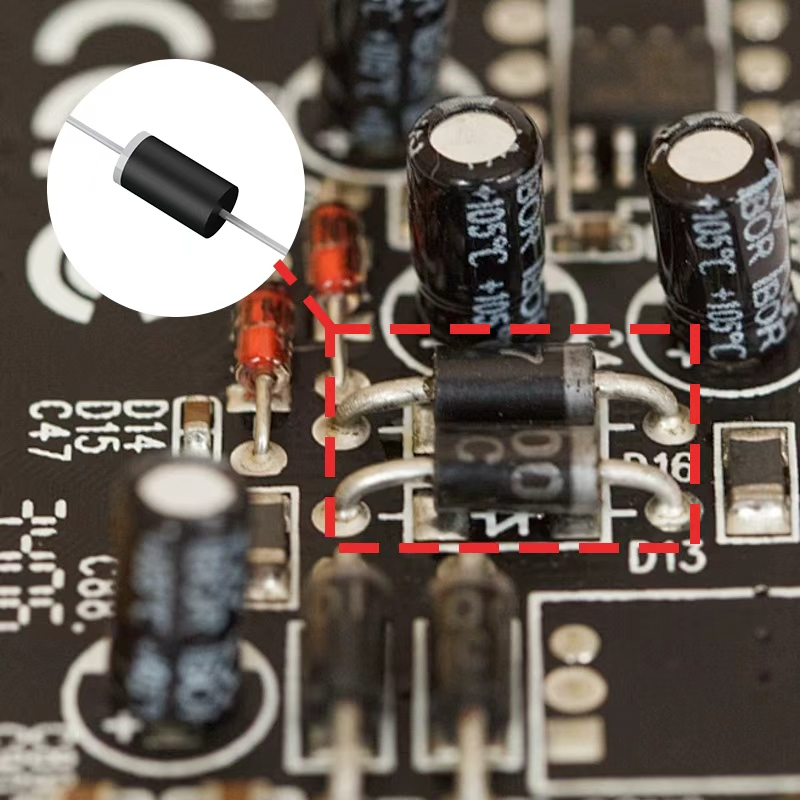

Case study: Diode failure due to incorrect biasing in power supply units

A 2023 analysis of industrial power supplies found that 62% of diode failures result from reverse voltage exceeding breakdown limits. One documented incident involved incorrect AC/DC rectifier wiring, leading to sustained 12V reverse bias. This triggered thermal runaway at 150°C, culminating in catastrophic junction failure within eight minutes.

Rectification and Voltage Regulation Using Diodes for Stable Circuits

Role of rectifier diodes in converting alternating current to direct current

Rectifier diodes enable AC-to-DC conversion by conducting only during forward-biased portions of the AC cycle. In full-wave bridge configurations, they utilize both halves of the waveform, achieving up to 98% conversion efficiency—significantly outperforming half-wave designs, which waste about 40% of input energy.

Half-wave vs. full-wave rectification: Efficiency and ripple implications

Half-wave rectifiers produce pulsating DC with 120Hz ripple in 60Hz systems, while full-wave rectifiers double the ripple frequency to 120Hz, reducing amplitude by 68%. However, bridge rectifiers introduce two diode drops (1.4V total), increasing conduction losses and requiring effective thermal management in high-power applications.

Zener breakdown characteristics and their application in voltage regulation

Zener diodes exploit controlled reverse-bias breakdown to maintain precise reference voltages ranging from 2.4V to 200V. Temperature-compensated variants achieve ±1% tolerance, making them ideal for protecting sensitive ICs during voltage transients. Their clamping action stabilizes output without interrupting circuit operation.

Maintaining stable voltage outputs under fluctuating load conditions

Advanced regulators combine Zener diodes with transistor buffers to limit output variation to less than 2% across 0—100% load changes. With thermal derating and adaptive current limiting, these circuits sustain reliable performance for over 50,000 hours in demanding industrial environments.

Diode-Based Protection Against Overvoltage, Surge, and Reverse Polarity

Clamping Voltage Spikes to Safe Levels With Transient Voltage Suppression Diodes

TVS diodes for transient voltage suppression act incredibly fast, often within a fraction of a billionth of a second, to redirect harmful electrical surges from events like static discharge or lightning strikes. These spikes can sometimes reach over 20 kilovolts in factory environments. What makes them different from regular fuses is their ability to limit voltage levels to what's considered safe while still allowing normal operation to continue after the surge passes. The systems just reboot themselves without needing replacement parts. For critical applications where downtime isn't an option, such as aircraft navigation systems or cell tower communications equipment, having this kind of protection becomes absolutely necessary. Without proper safeguards against these unpredictable power spikes, expensive electronic components would fail much more frequently.

Reverse Polarity Protection in DC Circuits: Preventing Catastrophic Damage

Accidental battery reversal in 12—48V systems can destroy components within milliseconds. Diode-based protection reduces equipment damage rates by 89%, per a 2025 Journal of Circuit Protection study. Series diodes block reverse current, while shunt configurations trigger fuse disconnection before critical components are compromised.

Blocking Reverse Current Flow in Battery-Powered Systems

In automotive and renewable energy applications, diodes prevent parasitic discharge through unintended paths. High-efficiency Schottky diodes, with just a 0.3V forward drop, are now standard in 48V electric vehicle architectures. By minimizing energy loss and eliminating reverse leakage—a factor in 17% of historical battery failures—they enhance system reliability.

Phenomenon: Surge-Induced Failures in Unprotected Automotive Electronics

Alternator load dumps generate voltage transients that destroy 23% of unprotected ECUs annually. The integration of 80V-rated TVS diodes in ADAS platforms has improved surge survival rates to 99.8%, clamping 40V spikes down to 28V within 5 nanoseconds. Such protection is now required in vehicles compliant with ISO 16750-2 standards.

Ensuring Long-Term Circuit Integrity Through Diode Reliability

How Diode Aging Affects Performance in Industrial Control Systems

Diodes tend to break down over time, according to research that found their turn off speed drops by around 39% and reverse recovery charge falls about 30% after being used non stop for 16 years. This kind of degradation causes problems for motor drives and PLC systems, since even tiny rises in leakage current something like 0.2 microamps per year can mess up control signals completely. A look at real world failures shows just how serious this issue is. The 2023 analysis of 142 major industrial shutdowns pointed directly at worn out diodes as the main problem behind roughly one fifth of those incidents.

Thermal Stress and Its Influence on Diode Lifespan

Irreversible semiconductor degradation begins when junction temperatures exceed 200°C. For every 10°C rise above rated limits, power diode failure rates increase by 1.8. Industrial environments intensify this stress through cyclic thermal expansion in surface-mount packages, heat concentration in rectifier bridges, and insulation breakdown during prolonged operation above 85°C.

Industry Paradox: High-Efficiency Diodes Versus Long-Term Reliability Trade-Offs

While modern fast-recovery diodes reach 98.7% conversion efficiency, they exhibit a 40% shorter median lifespan than traditional silicon diodes due to inherent material trade-offs:

| Parameter | Standard Diode | High-Efficiency Diode |

|---|---|---|

| Forward Voltage Drop | 0.7V | 0.3V |

| Mean Time Between Failures | 150,000h | 82,000h |

| Thermal Resistance | 35°C/W | 58°C/W |

Strategy: Implementing Zener Diodes in Low-Power Voltage Reference Circuits

Precision Zener diodes deliver ±0.05% voltage stability over 10,000 hours when used with appropriately sized current-limiting resistors (120% of nominal load), temperature-compensated packaging, and cleanroom-grade passivation. This configuration cuts calibration needs by 73% in measurement instruments while keeping power dissipation below 50mW.

Frequently Asked Questions

What is a diode and how does it function?

A diode is a semiconductor device that allows unidirectional current flow. It functions by creating a barrier, known as a P-N junction, which blocks reverse current under normal conditions.

Why are diodes important in circuit protection?

Diodes are crucial for preventing backflow of electricity that can damage equipment. They are also used in voltage regulation and rectification to provide stable and efficient circuit performance.

How do Zener diodes differ from regular diodes?

Zener diodes are designed to allow current to flow in the reverse direction when a specific voltage, known as Zener voltage, is reached. They are used for voltage regulation and maintaining stable outputs during voltage transients.

What factors can lead to diode failure?

Diode failure is often caused by incorrect biasing, excessive thermal stress, or aging over long-term use which affects their performance characteristics.

How can diodes protect against reverse polarity?

Diodes can block reverse current flow or disconnect the circuit in case of accidental battery reversal, preventing catastrophic damage to components.

Table of Contents

-

How Diodes Control Current Flow to Protect Circuit Integrity

- Understanding diode functionality and unidirectional current flow mechanisms

- Forward-bias and reverse-bias operation: How diodes regulate current direction

- Semiconductor fundamentals: P-N junctions explained

- Diode current flow characteristics under varying voltage conditions

- Case study: Diode failure due to incorrect biasing in power supply units

- Rectification and Voltage Regulation Using Diodes for Stable Circuits

- Diode-Based Protection Against Overvoltage, Surge, and Reverse Polarity

- Ensuring Long-Term Circuit Integrity Through Diode Reliability

- Frequently Asked Questions