The Evolving Challenge of Electromagnetic Interference in Modern Electronics

Electronics today are dealing with electromagnetic interference problems that have gotten much worse over the past few years. Studies from 2023 show these issues have actually increased by around 47% since 2018, mainly because gadgets are getting smaller while also being packed with more wireless capabilities. The situation has only gotten worse as 5G rolls out everywhere, smart devices become part of daily life, and power supplies operate at higher frequencies than ever before. All this means designers need to pay serious attention to EMI filtering when creating new products these days.

Understanding electromagnetic interference (EMI) in electronic devices

EMI occurs when electromagnetic radiation disrupts a device's operation, manifesting as signal distortion, data corruption, or complete system failure. Two primary EMI categories exist:

- Natural sources: Cosmic radiation, solar flares, and atmospheric discharges

- Manmade sources: Switch-mode power supplies, wireless transmitters, and high-speed digital circuits

The global cost of EMI-related equipment failures exceeds $740 billion annually (Ponemon Institute, 2023), highlighting the urgency for effective mitigation strategies.

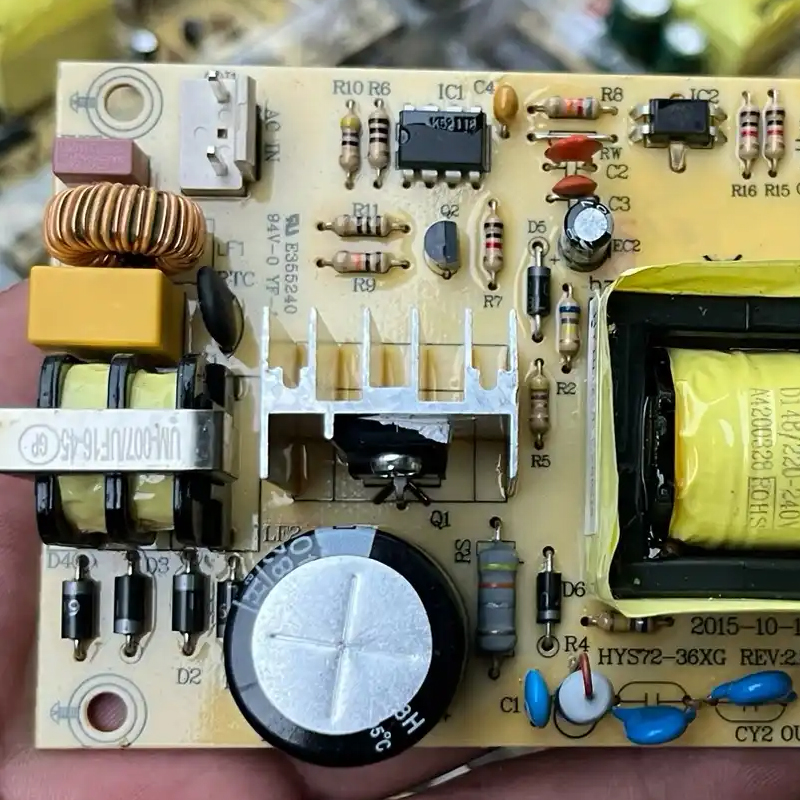

Conducted and radiated EMI in switch-mode power supplies

Modern switch-mode power supplies face dual EMI challenges:

| EMI Type | Transmission Path | Frequency Range | Common Mitigation |

|---|---|---|---|

| Conducted EMI | Power/ground lines | 150 kHz - 30 MHz | Ferrite chokes |

| Radiated EMI | Electromagnetic fields | 30 MHz - 1 GHz | Shielding cans |

Recent studies show 68% of power supply failures stem from inadequate EMI filtering (integrated active filtering research, 2023), particularly in compact designs where component proximity amplifies interference risks.

The impact of high-power-density electronics on EMI challenges

The push for smaller, more powerful devices has increased power density by 300% since 2015, creating three critical EMI challenges:

- Reduced physical space for traditional filter components

- Higher thermal loads altering material characteristics

- Increased parasitic capacitances in tightly-packed circuits

This density-heightened EMI environment requires innovative solutions like embedded passives and adaptive filtering algorithms to maintain signal integrity without sacrificing performance.

Advancements in Semiconductor Technology and EMI Filter Integration

How Shrinking Node Sizes Increase EMI Susceptibility in Semiconductors

Pushing semiconductor nodes down to sub-10 nm scales has created unexpected problems with electromagnetic interference. When these tiny components get packed so close together, strange things happen with their electrical properties. The parasitic capacitances between them start acting like little antennas, while inductive couplings turn into noise amplifiers at high frequencies. According to research published last year by the IEEE EMC Society, shrinking below 28 nm makes circuits about 20% more vulnerable to EMI issues because there's less room for error margins and everything switches on and off much faster. Manufacturers are now forced to incorporate specialized EMI filters just to keep these ultra compact chips from causing signal problems. Some experts argue this might be why we're seeing more emphasis on packaging solutions as well.

Industry Trends in Semiconductor Solutions for EMI Reduction

Manufacturers are increasingly turning to co-packaged EMI mitigation systems these days, which bring together sophisticated filtering materials alongside smart layout approaches. According to recent market research from 2024, about two thirds of newly released power management ICs come with some kind of built-in EMI suppression capability. That's quite a jump from just over 40% back in 2020. The latest controller designs go even further by incorporating active noise cancellation technology inside them. These integrated solutions manage to cut down interference by around 15 dB compared to traditional separate components, all while taking up roughly 30% less room on circuit boards. For engineers working within tight space constraints, this represents a real breakthrough in performance versus footprint tradeoffs.

Integration of EMI Filtering Within Semiconductor Devices

Three key integration strategies are reshaping EMI filter implementation:

- On-die decoupling networks using high-k dielectric materials

- Current-balancing architectures in voltage regulators

- Adaptive impedance matching for frequency-selective attenuation

These integrated approaches reduce parasitic losses by 45% compared to traditional external EMI filters while maintaining compliance with FCC Part 15 Class B emissions standards. However, thermal management remains challenging in designs where filtering components share silicon real estate with high-power transistors.

Miniaturization and Design Innovation in EMI Filter Development

EMI Filter Miniaturization and Space-Saving Designs in Modern PCBs

Modern electronics now require EMI filters occupying 68% less PCB space than 2019 designs, driven by 5G infrastructure demands and wearable device constraints. Multilayer ceramic capacitors with integrated filtering functions reduce component counts by 40% while maintaining 60dB noise suppression at 100MHz frequencies.

Material Science Breakthroughs Enabling Smaller EMI Filters

Nano-crystalline core materials achieve 92% flux density improvements over traditional ferrites, enabling 3mm² filter footprints without sacrificing thermal stability. Recent advancements in conductive polymer composites now suppress 0.1–6GHz interference with 85% efficiency in 1.2mm-thick configurations.

Trade-offs Between Size Reduction and Filtering Efficiency

Shrinking filter dimensions typically increases parasitic capacitance by 15–25%, requiring innovative impedance matching networks. Designers compensate through:

- Frequency-selective shielding layers

- Adaptive damping circuits

- 3D inductor winding techniques

Case Study: Miniaturized EMI Filters in Wearable Consumer Electronics

A recent smartwatch implementation demonstrates 2.8mm³ EMI filters reducing switching noise from PMIC modules by 73dBμV/m – meeting EN 55032 Class B requirements while consuming 35% less board space than previous generations.

Active vs. Passive EMI Filtering: Performance, Complexity, and Use Cases

Fundamental Differences Between Active and Passive EMI Filters

EMI filters come in two main types - active and passive - and they tackle electromagnetic interference in completely different ways. Passive ones work by combining resistors, caps, and coils to block out those pesky unwanted frequencies. The nice thing about them is they don't need any outside power source to function. Active filters are another story altogether though. These bad boys actually use op-amps and require external power to go on the offensive against interference signals. According to some recent testing done last year, there are quite a few important differences between these approaches worth noting.

| Feature | Active Filters | Passive Filters |

|---|---|---|

| Power Requirement | Yes | No |

| Frequency Range | Optimized for low frequencies | Effective at high frequencies |

| Signal Gain | Amplification possible | Attenuation only |

| Cost | 15–30% higher | Lower upfront cost |

Active EMI Filters in Power Supply Design for Noise Cancellation

In complicated power supply situations where getting rid of unwanted noise matters a lot, active filters really stand out. They work kind of like those fancy noise canceling headphones we all know about these days, but instead of sound waves they're dealing with electrical signals. The way these filters operate involves sending out opposite phase signals that basically cancel out the interference. Big name companies in this space have started putting smart adaptive algorithms right into their integrated circuits lately. This has cut down on how much physical space external filters need by somewhere around half according to most reports, and still keeps everything within the rules set forth by FCC Part 15B regulations for electromagnetic compatibility.

Real-Time Adaptive EMI Filtering Systems Using Feedback Control

Modern active filters employ real-time impedance monitoring and digital signal processing (DSP) to adjust filtering parameters within microseconds. This capability proves vital in industrial robotics and 5G infrastructure, where EMI profiles change rapidly. For instance, adaptive systems can suppress transient noise spikes exceeding 80 dBµV without compromising signal integrity.

Controversy Analysis: Are Active Filters Worth the Complexity Premium?

Active filters do cut down on components needed for dense circuit boards, but they come at about 1.5 to 2 times the price of alternatives which has caused quite a discussion among engineers. Many folks still think passive options work fine for around seven out of ten commercial uses under 500 kilohertz frequencies. On the flip side, supporters point to long term advantages. Recent research from last year found that cars with advanced driver assistance systems had 22 percent fewer problems in the field when using these special EMI suppression techniques. At the end of the day, it really comes down to if the better performance is worth dealing with more complicated designs depending on what specific project we're talking about.

System-Level Integration of EMI Filters in 5G and High-Frequency Applications

Integration of EMI Filters in System Designs for Signal Integrity

The latest 5G systems really need those specially designed EMI filters if they want to keep signals clean in all those crowded circuits. According to some industry research from 2024, about 8 out of 10 problems with 5G RF devices actually come down to poor EMC planning when putting everything together. These days engineers are focusing on these multi stage filter setups because they tackle both the lower frequency stuff (up to around 30 MHz) and the higher end noise above 1 GHz frequencies, especially important for those powerful baseband processors. What this means practically is that bit errors drop somewhere between 40 and 60 percent in those mmWave communication setups compared with older designs, which makes a huge difference in real world performance.

5G Technology Challenges for EMI Shielding and High-Frequency Filtering

The transition to 5G's 3.5–7.125 GHz frequency bands has exposed critical gaps in traditional shielding methods. At 28 GHz mmWave frequencies, skin depth effects diminish shielding effectiveness by 72% compared to sub-6 GHz applications (Industry Report 2024). Engineers combat this through hybrid solutions:

- Conductive gaskets with 80 dB attenuation at 6 GHz

- Frequency-selective surfaces (FSS) for directional shielding

- Adaptive EMI suppression algorithms using real-time impedance matching

Higher Frequency Range Requirements for EMI Filters in RF-Dense Environments

Emerging Wi-Fi 7 (5.925–7.125 GHz) and satellite communication (12–40 GHz) standards push EMI filters beyond traditional limits. Current R&D focuses on:

| Parameter | Legacy Filters | Next-Gen Requirement |

|---|---|---|

| Frequency Range | DC – 6 GHz | DC – 40 GHz |

| Insertion Loss | < 1 dB @ 2 GHz | < 0.8 dB @ 28 GHz |

| Common-Mode Rejection | 30 dB | 45 dB |

Materials like nickel-zinc ferrites and liquid crystal polymer substrates now enable 91% near-field coupling reduction at 24 GHz, addressing interference in phased-array antenna modules (Materials Science Advances 2023).

Frequently Asked Questions (FAQs)

What is electromagnetic interference (EMI)?

EMI is the disruption that electromagnetic radiation causes to the performance of electronic devices, which can result in signal distortion, data corruption, or system failures.

Why has EMI become a bigger issue in recent years?

The increase in EMI issues is mainly due to the miniaturization of devices, the increase in wireless capabilities, and the introduction of high-frequency power supplies like 5G technology and smart devices.

What are the differences between active and passive EMI filters?

Active filters require external power and are capable of amplifying signals, making them better suited for low-frequency applications. Passive filters don't require external power and are effective at high frequencies, but they only provide attenuation.

Why is EMI filtering important in semiconductor technology?

As semiconductor nodes shrink to sub-10 nm scales, the components' electrical properties create challenges with EMI. Effective filtering is critical to prevent interference issues in such compact environments.

How does 5G technology impact EMI concerns?

The high frequency and dense environments of 5G push the limits of traditional EMI filtering and shielding techniques, necessitating advanced engineering solutions to maintain signal integrity.

Table of Contents

- The Evolving Challenge of Electromagnetic Interference in Modern Electronics

- Advancements in Semiconductor Technology and EMI Filter Integration

- Miniaturization and Design Innovation in EMI Filter Development

- Active vs. Passive EMI Filtering: Performance, Complexity, and Use Cases

- Fundamental Differences Between Active and Passive EMI Filters

- Active EMI Filters in Power Supply Design for Noise Cancellation

- Real-Time Adaptive EMI Filtering Systems Using Feedback Control

- Controversy Analysis: Are Active Filters Worth the Complexity Premium?

- System-Level Integration of EMI Filters in 5G and High-Frequency Applications

- Frequently Asked Questions (FAQs)