Explore how Y capacitors suppress EMI in SMPS, LED drivers, and industrial power systems, and learn key selection tips for better EMC performance and safety.

1. Product Overview

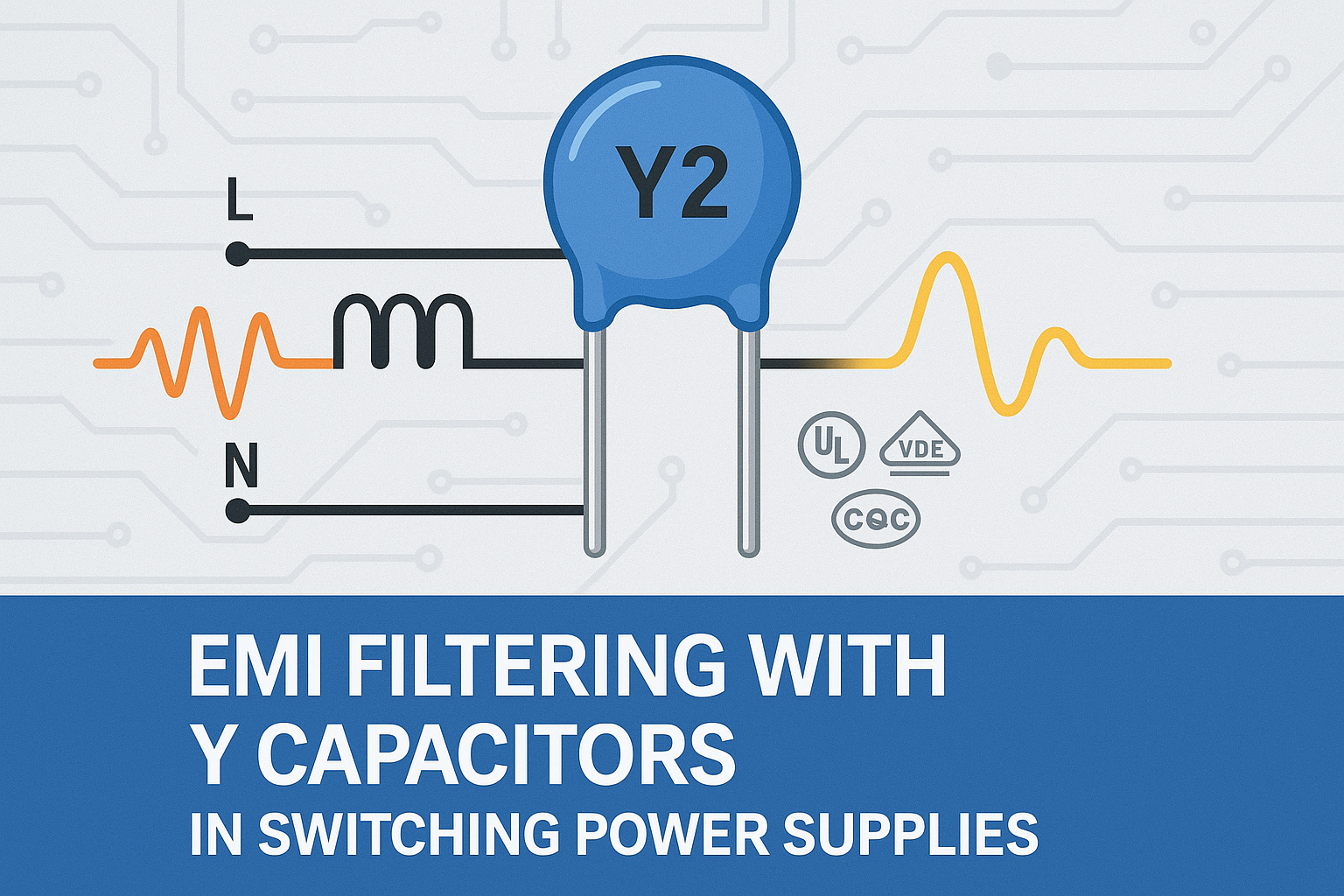

Y capacitors are a class of safety-certified components designed specifically to suppress common-mode electromagnetic interference (EMI). They are connected between the AC line (L/N) and ground (FG). Due to the fact that they are connected directly to the earth, any failure in a Y capacitor could pose a safety risk. Therefore, they must meet stringent international safety standards such as UL, VDE, and CQC.

Y capacitors are classified into:

Y1 Type: Designed for high-insulation applications (AC 250V, ≥ 4000V), typically used in industrial or reinforced insulation systems;

Y2 Type: Designed for general-purpose consumer electronics (AC 250V, ≥ 2500V).

Unlike X capacitors, which filter differential-mode noise, Y capacitors are optimized for common-mode EMI suppression, especially in the 150kHz–30MHz conducted noise range.

2. EMI in SMPS and the Function of Y Capacitors

In switching mode power supplies (SMPS), high-speed switching components such as MOSFETs generate EMI. This noise may travel through power lines or radiate outward, affecting nearby equipment and potentially causing the system to fail EMC tests.

Common-mode noise results from high-frequency potential differences between the ground and internal nodes of the device. If not properly controlled, this can lead to communication errors, malfunctioning sensors, or system resets.

Y capacitors:

Work with common-mode chokes to form efficient EMI filters;

Provide a low-impedance path to discharge high-frequency noise to ground;

Significantly reduce the amplitude of common-mode conducted noise, enabling compliance with EMI standards like EN 55032 or CISPR 32.

In AC-DC power modules, the correct selection and layout of Y capacitors is crucial for passing conducted emission tests and ensuring product safety.

3. Selection Guidelines for Y Capacitors

Safety Classification

Use Y1 capacitors for industrial or reinforced isolation systems;

Use Y2 capacitors in consumer or portable applications to balance cost and performance.

Capacitance Range

Typically between 470pF and 4700pF;

Total capacitance must keep leakage current below safety limits (e.g., <0.75mA) to avoid shock hazards or GFCI tripping.

Dielectric Material & Reliability

Ceramic capacitors are widely used due to their high-frequency performance and stability;

Film capacitors may be preferred in high-humidity or high-temperature environments.

Layout Considerations

Place Y capacitors close to the EMI filter input;

Use short, wide PCB traces to reduce parasitic inductance and improve filtering effectiveness.

4. Case Study: Y Capacitor Design in LED Drivers

In LED drivers, Y capacitors play a vital role in EMI compliance. These systems are sensitive to noise, and poor EMI suppression may result in flickering or erratic operation.

In one LED lighting design, two 2200pF Y2 capacitors were added to the input filter. This reduced common-mode noise by over 15dB, ensuring that the product met EN55015 Class B standards with margin.

5. Conclusion

Y capacitors are indispensable components in modern EMI suppression designs. Their proper application enhances product reliability, safety, and market compliance. From consumer electronics to industrial power systems, selecting the right Y capacitor ensures long-term stability and optimal EMI performance.

Y capacitors | EMI suppression | Y1/Y2 capacitors | EMC filter design | Power supply anti-interference