This article introduces application examples of fast recovery diodes in automotive power systems, covering parameter selection, industry scenarios, and technology trends. It serves as a selection and procurement guide for engineers.

I. Product Overview: Characteristics and Packaging of Fast Recovery Diodes

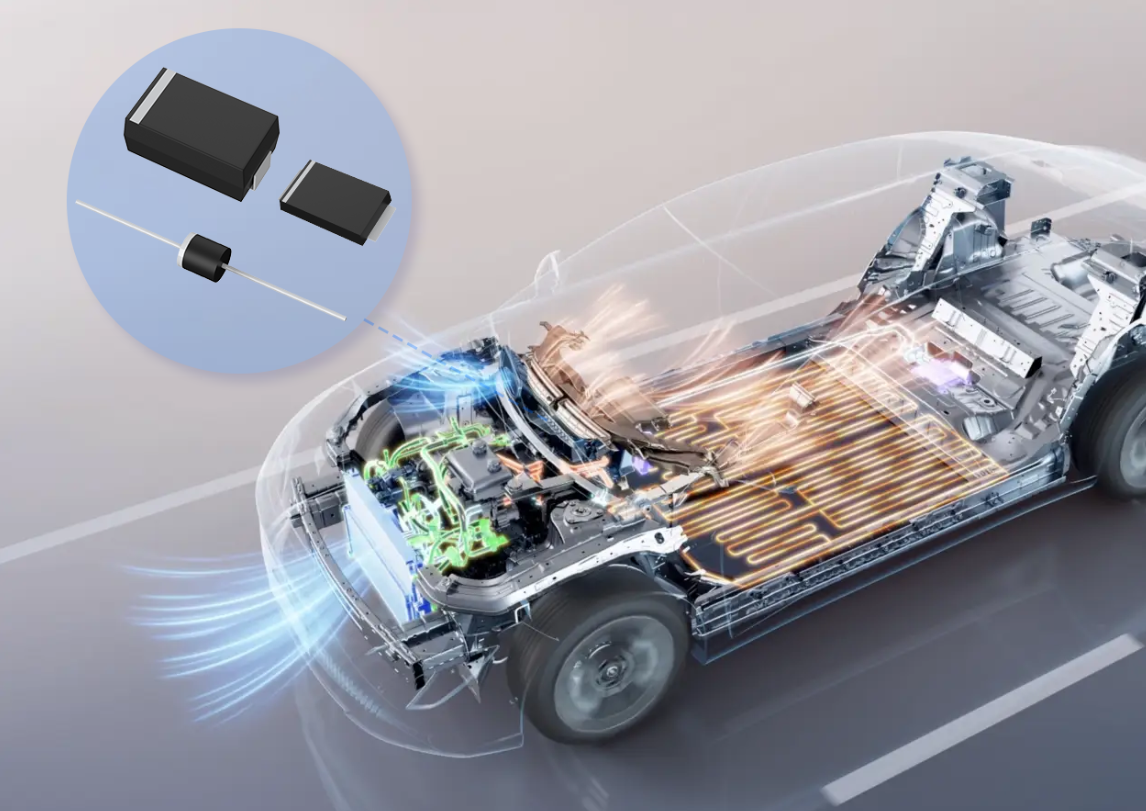

Fast Recovery Diodes (FRDs) are rectifiers with a fast reverse recovery capability, typically between 150ns and 500ns. Compared to standard rectifiers, FRDs are optimized for high-speed switching and transient response, making them ideal for use in switching power supplies, DC-DC modules, and automotive electronics.

The SMA package, known for its compact size and efficient heat dissipation, is widely used in surface-mount automotive rectifier modules, onboard chargers, and vehicle control systems. It supports automated SMT processes while maintaining excellent electrical performance.

II. Industry Application: High-Frequency Rectification in Automotive Electronics

As automotive systems evolve toward higher intelligence and electronic integration, the stability and transient response of power modules become critical. Fast Recovery Diodes play pivotal roles in the following modules:

1. ECU Control Modules

Rectify high-frequency PWM signals and suppress voltage spikes

Paired with MOSFETs to enhance efficiency and withstand voltage stress

2. Onboard Chargers and USB PD Modules

Handle rectification and freewheeling under high-frequency current input

Reduce reverse recovery losses to improve system efficiency

3. Automotive Lighting Systems (LED Drivers)

Fast recovery prevents flickering in lighting systems

Withstands transients and extends LED lifespan

III. Technical Parameters and Selection Guidelines

|

Parameter |

Range |

Application Notes |

|

Maximum reverse voltage VRRM |

100V ~ 600V |

For high-voltage motor drives, 400V+ is recommended. |

|

Forward current IF |

1A ~ 3A |

Determine the redundancy margin based on the load current. |

|

Forward voltage drop VF |

0.85V ~ 1.2V |

Lower VF results in higher efficiency and are suitable for high-frequency power supplies. |

|

Recovery time trr |

150ns ~ 500ns |

For high-frequency PWM applications, products with a trr < 200ns are recommended. |

|

Operating temperature range |

-55°C ~ +150°C |

Meet automotive-grade temperature requirements. |

These parameters highlight the performance flexibility of SMA-type FRDs across a range of automotive and industrial applications. A faster trr and lower VF contribute directly to efficiency and thermal stability.

IV. Case Study: Power Protection in Smart Cockpit Designs

In the design of a smart cockpit infotainment system, an automaker selected a 200V/2A FRD as the input rectifier. Compared to a conventional rectifier solution, this approach reduced thermal losses by 25% and provided better voltage stability during MCU hot-start phases.

With careful component selection, the working temperature of the cockpit module dropped by 8°C, enhancing reliability and passing stringent automotive EMC tests.

V. Future Trends: Faster, Smaller, and More Integrated

Fast Recovery Diodes will evolve toward lower trr, lower VF, miniaturization, and higher packaging integration. In the future, they will be co-packaged with MOSFETs and driver ICs, forming single-chip rectification modules.

Automotive-grade products will reinforce AEC-Q101 qualification and continue expanding into autonomous driving and smart grid domains.