Learn how bridge rectifiers enable reliable AC-DC conversion in EV chargers, LED systems, and industrial controllers. Discover brand models, parameters, and global sourcing.

I. Product Overview and Operating Principle

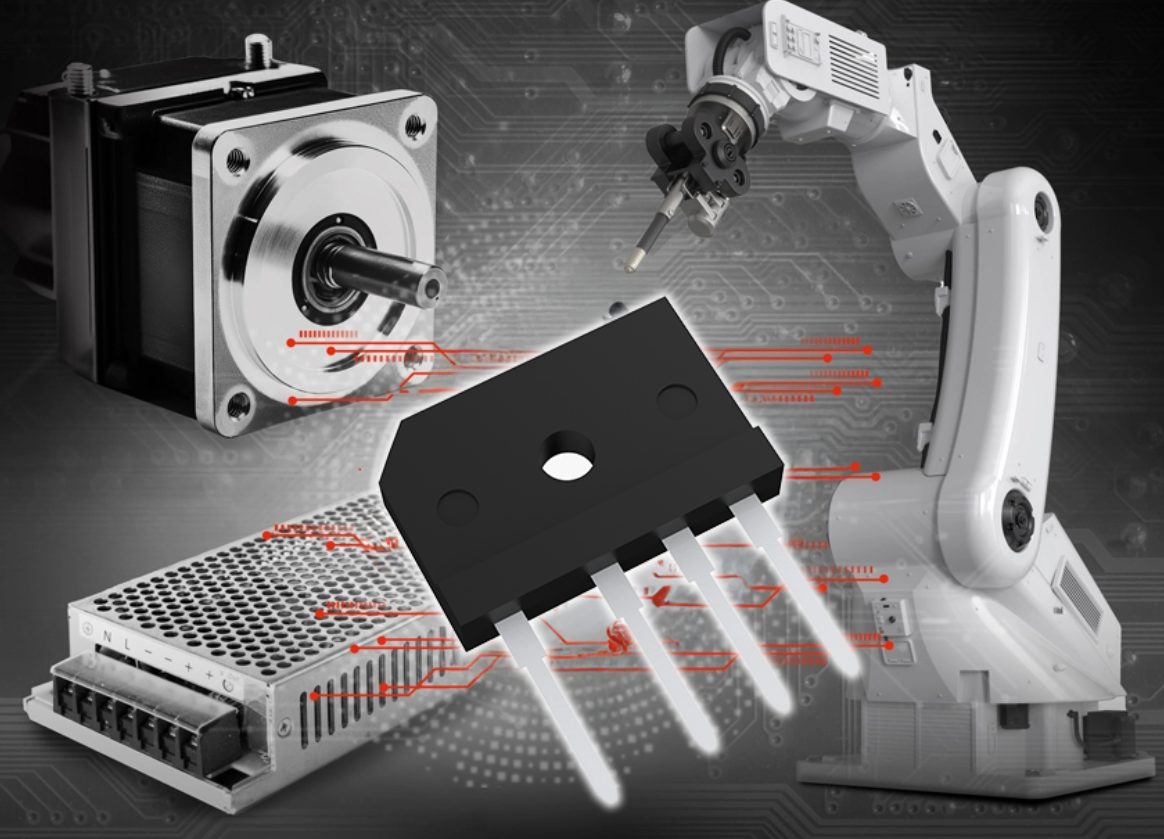

A bridge rectifier is an arrangement of four diodes in a bridge configuration that converts alternating current (AC) input into direct current (DC) output. Due to its compact form factor and efficient rectification capability, it is widely used across power supplies, motor drivers, lighting circuits, and more.

Mainstream package types include surface-mount (e.g., MBLS, GBU, ABS), through-hole (e.g., KBPC, KBU, KBP), and metal casing types (e.g., SKBPC), covering applications from low-power home appliances to high-voltage industrial machines.

II. Typical Application Scenarios

1. Industrial Control Power Supplies: Bridge rectifiers are critical in the input section of industrial cabinets, converting 220V/380V AC into stable DC for devices like PLCs, relays, and servo drivers.

2. Motor Drives for Power Tools: Power tools such as drills and electric wrenches rely on rectifiers for DC link generation. Combined with capacitors and switching devices like IGBT/MOSFETs, they power downstream drive circuits efficiently.

3. LED Lighting Systems: Bridge rectifiers in LED drivers convert AC to DC, working with constant current controllers and PWM ICs to ensure stable, flicker-free lighting.

4. EV Charging Stations & Renewable Systems: High-current bridge rectifiers (e.g., 25A–50A, 600V–1000V) are essential in electric vehicle chargers and solar inverters, feeding energy into DC-DC conversion stages.

III. Key Technical Parameters

|

Parameter |

Typical Range |

|

Rated current / IF |

1A ~ 50A |

|

Reverse voltage / VRRM |

50V ~ 1200V |

|

Forward voltage drop / VF |

0.9V ~ 1.2V |

|

Peak surge current / IFSM |

30A ~ 500A |

|

Operating temperature / Tj |

-55°C ~ +150°C |

These parameters help engineers select the appropriate models based on system voltage, current, and thermal conditions.

IV. Procurement and Supply Considerations

Leading brands such as LRC, MCC, Vishay, Taiwan Semiconductor, and ON Semiconductor offer a full range of bridge rectifiers, covering 1A to 50A and voltages up to 1200V.

We offer spot inventory, fast delivery, BOM kitting, and multi-currency transactions (USD, RMB) from our Shenzhen and Hong Kong warehouses, catering to clients from India, Vietnam, Turkey, Eastern Europe, and Mexico.

V. Conclusion: Future Trends of Bridge Rectifiers

With the miniaturization of industrial electronics, future bridge rectifiers will feature more SMD packages, lower VF technologies, and integrated thermal protection for enhanced performance.

As industries like EVs and energy storage evolve, bridge rectifiers remain indispensable in the power infrastructure due to their efficiency and robustness.