Arwilio amryw o gyfresau diogelu polarwedd sy'n ôl ar gyfer ymatebion car goreutu, gan gynnwys diodau Schottky, MOSFETau P-/N-dolfan, a solusionau seiliedig ar gydal rheolwyr. Ymarferol ar gyfer systemau BMS, ECUs car a modiwlau dynameg EV gyda chyflwr isel a chyfrifoldeb cyflym ar gyfer anghofnodi dynol a statig.

—— Technegeu Sylwadau Polarytet Gyfnewidig

1. Beth yw Amynachder Polarytet Gyfnewidig?

Amynachder Polarytet Gyfnewidig (RPP) yn cael ei ddefnyddio i atal dioddef i systemau pan mae bateri yn cael ei gysylltu'n gyfnewidig. Mae'n cael ei weld yn gyffredinol yn systemau powr arbenig, Systemau Rheoli Bateri (BMS), a chyfrifoldeb moddwlau mewnbwn DC is-bardd.

Mae gan giro amynachder polarytet gyfnewidig tri math sylfaenol:

- Diod safonol y setiau/Schottky

- MOSFET rhial P-gyfer

- MOSFET rhial N-gyfer

2. Ymwybyddion Cyffredinol Arwain Dwylyd Cyfesurynnol

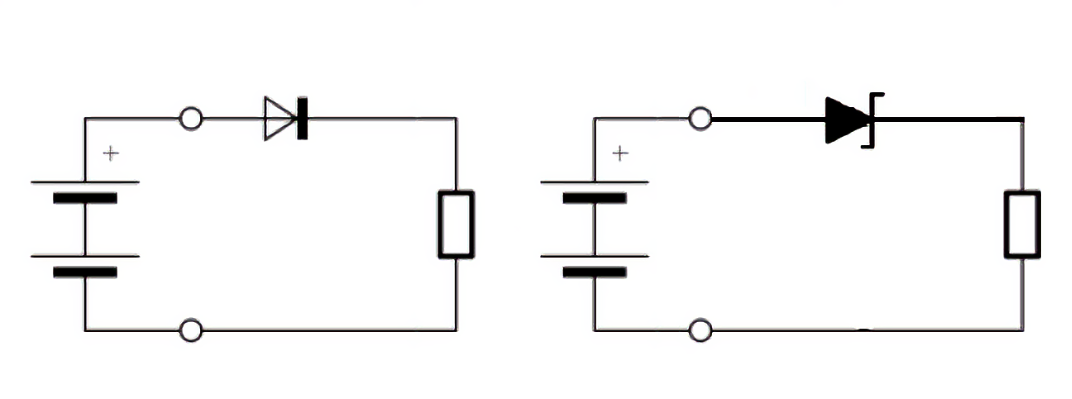

2.1 Dull Setiau Diode

Principiol sylfaenol: Mae diod safonol neu Schottky yn cael ei leoli mewn cyfres â'r rail grefydd positif ac mae'n llwgo yn unig pan mae'r polariti'n gywir.

Cyd-destun Technegol:

|

Math |

Swmpio Argyfwng (V) |

Manteision |

Anabuddion |

|

Diod Safonol |

0.7 ~ 1.0 |

Syml, cost yn isel |

Lwythfrydedd uchel, colli llawer o drefn |

|

Diod Schottky |

0.2 ~ 0.5 |

Lwythfrydedd isel, effeithlonrwydd uchel |

Amlwg fwy o arfwyddiaeth |

Gwneud defnydd: Arbrofiadau is-gyfradd, neu arbrofiadau sensitif i gost.

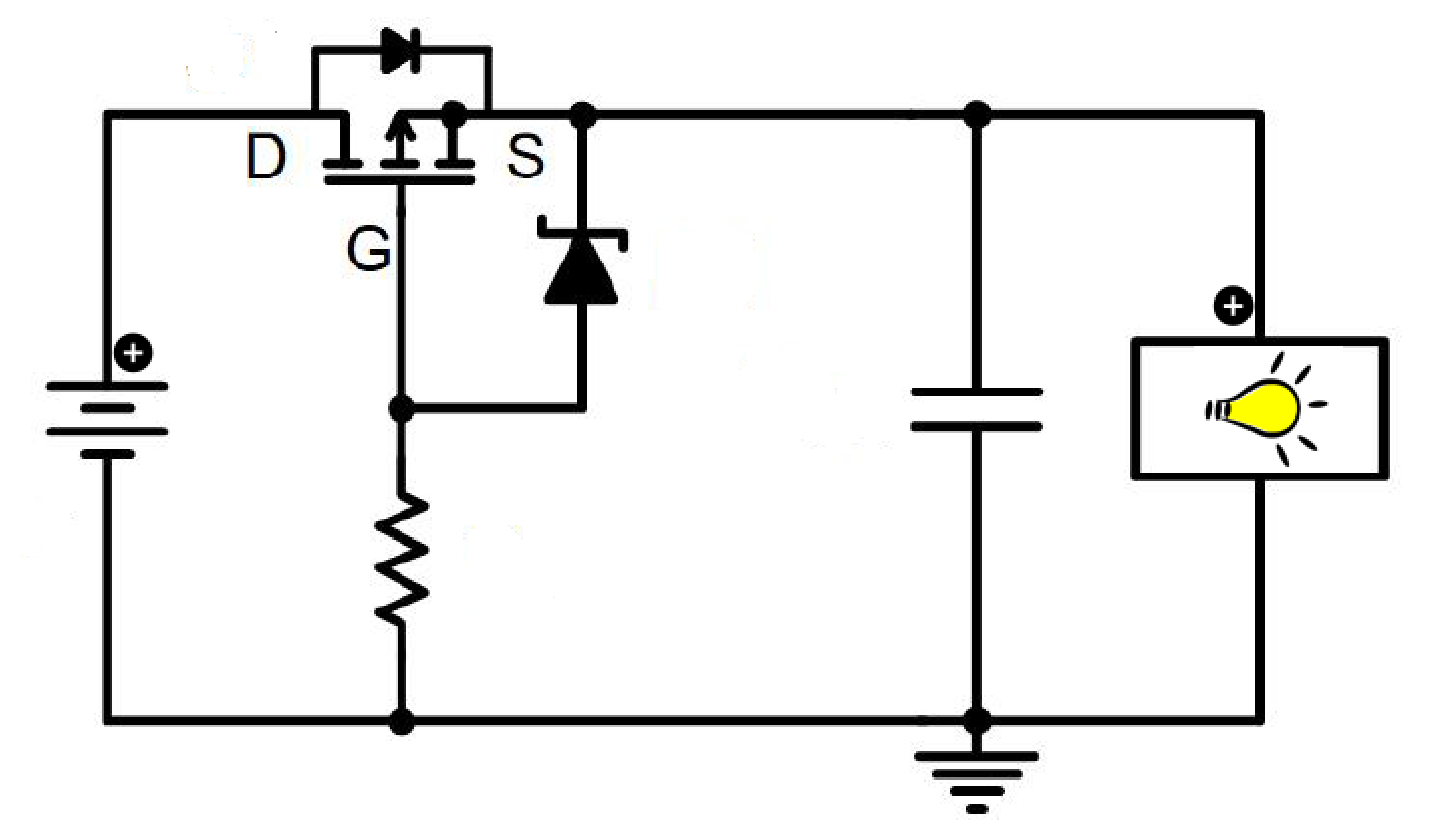

2.2 Ddatblygiad MOSFET Llwyfan P (Argymhellyd)

Strwythur Cylchyn: Mae MOSFET llwyfan P yn cael ei leoli yn gyfesurynnol â'r rail grefydd positiw, a thrwy ddefnyddio diod Zener i amgylchedd y gat.

Gynllun Gweithio:

- Pan mae'n cael ymateb yn gywir, mae'r didiod corff y MOSFET yn cyflwyno, ac mae'r terminal Ffynhonnell yn derbyn foltiwg bateri.

- Mae'r Gat ar 0V, yn ei gyffwrdd â Vgs yn nechyll, ac yn agor y MOSFET.

- Mae'r diod Zenydd yn cyfyngu Vgs i'w foltiad arosol.

Pryd yn bwrw'n wyneb: Mae'r diod corff yn beirniadu yn ôl, mae'r MOSFET yn gau, mae'r cylchyn yn brwnt, a mae'r system yn cael ei ddiogelu.

Pawblygiadau: Amheuaeth gorau llai wrth iddi fod yn agored, potensial llai o herwyddo gynulleidio na chynlluniau. Does dim ofynnwr allanol angen.

Defnydd: Yn gyffredinol yn cael eu defnyddio mewn electronig motorol, UCAs, a chylchoedd cynnar BMS.

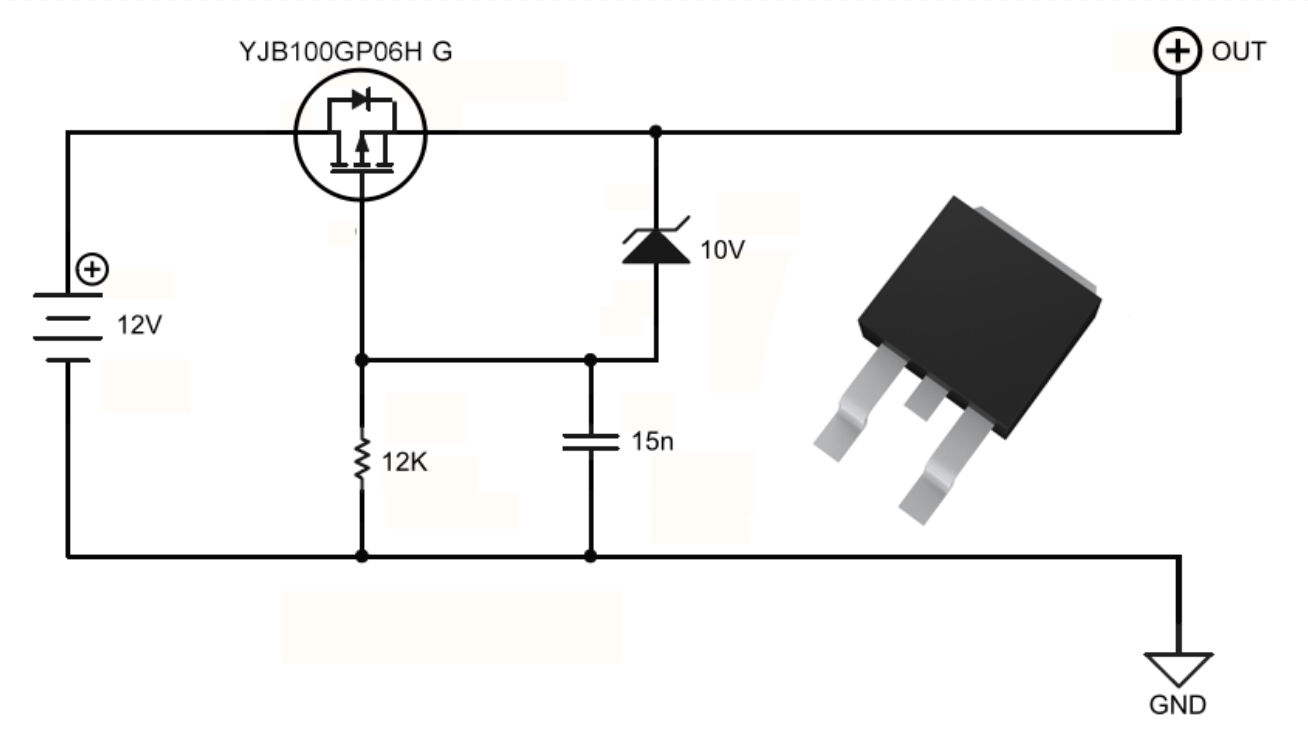

2.3 Gweldyn MOS N-Dros (Uchelgais Uchelgeisiol)

Nodweddion:

- Rds(on) ishwel na'r gweldyn P-dros, addas ar gyfer systemau gyrfa uchel.

- Mae angen ddyfarn pump neu drydydd llif i leisio Vgs uwch na Ffynhonnell.

Yn y cysylltiad gyfan: Mae diod corff yn cael ei beirniadu yn erchyll, mae drïo'r gat wedi'i ansablhau, a'r gweldyn MOS yn aros yn ddigwydd.

Gymhlethdod: Addas ar gyfer systemau effeithlon uchel fel rheolwyr EV cynyddol.

2.4 Datrysiadau sy'n seiliedig ar reolydd: RPP vs Rheolwyr Diod Ideali

|

Mater rheolwr |

Nodweddion |

Gwrthgysylltu Corn |

|

Rheolwr RPP |

Mae'n gweithio gyda MOSFET N-fanel, yn darparu amddiffyniad polarrwydd gwrthdaro yn unig |

Na |

|

Gynllunydd Diod Ideg |

Darparwyd diogelwch ar ôl cyfuniad + gwared ar droseddu amheusedd |

Ydw |

3. Dinamig vs Statig Ar ôl Cyfuniad

Ar Ôl Cyfuniad Statig: Cysylltiad ar ôl hir, mae angen amddiffyniad sylweddol.

Ar Ôl Cyfuniad Dynamig: Cysylltiad ar ôl cyfyngedig, er enghraifft trospledi llawer o waith, mae angen ymateb gyflym.

4. Amddiffyniad Rhelyg Gweithredol (Arbennig)

Manteision:

- Gallu cynyddu amperioedd uchel gyda chwympfiant ffon ar y cyfaint bachaf.

- Darparir toriadau llawn o'r cylchfan pan mae agored.

Anfanteision:

- Maint mawr, bys mesur yn bryderus.

- Ymateb llaeth, ddim addas i symudiadau gyffredin.

5. Crynodeb a Thywgraff Dewisiad

|

Math o Ddewisiad |

Defnydd o werin |

Cost |

Cyflymder Ymateb |

Amrediad Presennol |

Ymaterog Gweithred |

|

Diod Safonol/Schottky |

Canol i Uchel |

Isel |

Cyflym |

Isel i Canol |

Cylchoedd syml, systemau is-gyfradd |

|

P-Channel MOSFET |

Isel |

Canol |

Cyflym |

Canol i Uchel |

Pŵer arddull gyffredinol, diogelu BMS |

|

N-Channel MOSFET |

Ar ddiwedd lleiaf |

Canol |

Cyflym |

Uchel |

Rheoli pŵer uchel, modiwlau rheoli EV |

|

Gychwynnol-Weddi |

Isel |

Canol i Uchel |

Cyflym |

Canol i Uchel |

Ymyriadau presiwn, rheoli diwydiannol |

|

Relai |

Ar ddiwedd lleiaf |

Canol |

Llym |

Yn uchel iawn |

Isebyddu corfforol, amgylcheddau gyrfa mawr |