This article systematically introduces the structure, operating principle, package types, application scenarios, and selection parameters of bridge rectifiers, and also outlines their technological evolution.

I. What Is the Operating Principle of a Bridge Rectifier?

A bridge rectifier is a circuit composed of four diodes that convert alternating current (AC) into direct current (DC). In its standard topology, the positive and negative halves of the AC waveform are redirected to the same polarity at the load terminal, enabling full-wave rectification.

Compared to half-wave rectifiers that use only one half of the AC waveform, the bridge configuration is more efficient and delivers smoother output, making it the standard choice for AC-DC conversion in power supplies.

II. Common Use Cases of Bridge Rectifiers

Bridge rectifiers act as the "gatekeepers" in many AC-powered systems, converting wall power into usable DC. Here are some of the most common application scenarios:

1. Consumer Electronics Power Adapters

Bridge rectifiers are used at the front-end of power adapters in USB chargers, desk lamps, TVs, and more. They convert household AC power into DC voltage for further processing by switch-mode power supplies (SMPS).

2. Industrial Motor Control Systems

Bridge rectifiers play a key role in building high-voltage DC buses for industrial AC motor drives. In these systems, the rectifier is typically paired with large electrolytic capacitors to stabilize output.

3. LED Lighting and Power Modules

Bridge rectifiers are used in LED drivers to produce smooth DC voltage for constant current regulators, ensuring consistent brightness and efficiency.

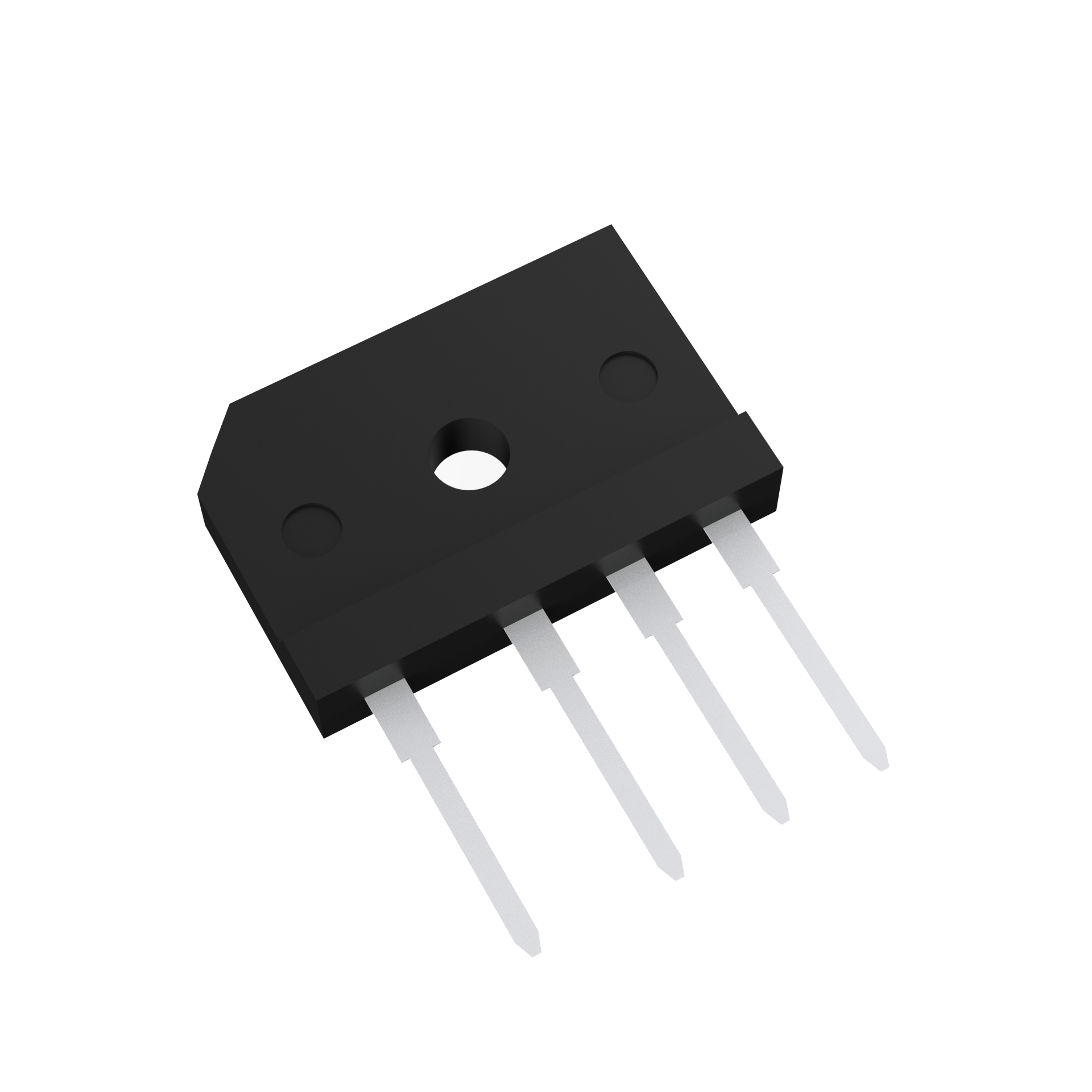

III. Common Packages and Current Ratings for Bridge Rectifiers

Bridge rectifiers are offered in several standard packages, depending on current and thermal requirements:

IV. How to Select the Right Bridge Rectifier?

When selecting a bridge rectifier, the following parameters are critical:

Maximum Forward Current (IF): Must support the circuit’s peak load current.

Peak Reverse Voltage (VRRM): Ideally 1.5 times the input AC voltage.

Surge Current Rating (IFSM): For startup or fault conditions.

Operating Temperature Range: Especially relevant for outdoor or industrial use.

Thermal Management: Metal cases or heat sinks for higher power applications.

V. Technology Trends: Miniaturization, High Density, and Integration

As power system designs trend toward smaller, higher-frequency, and more efficient solutions, bridge rectifiers are evolving as follows:

Use of Fast Recovery Diodes for better switching performance

Integration of EMI filtering and protection circuits

SMD replacing through-hole for space-saving

Silicon Carbide (SiC) rectifiers entering high-voltage market

Bridge Rectifiers | AC-DC Conversion | Rectifier Modules | Power Supply Design