How TVS Diodes Work: Ultrafast Clamping via Avalanche Breakdown

Avalanche breakdown physics enabling nanosecond response to transients

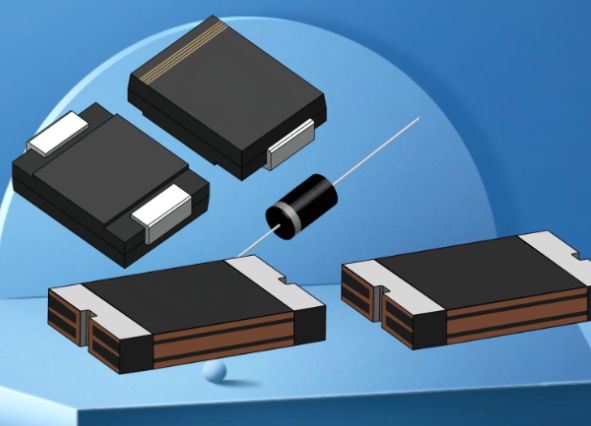

TVS diodes shield electronic circuits from damage in just fractions of a second thanks to their clever use of controlled avalanche breakdown in silicon that's been reverse biased. When there's a sudden spike in voltage beyond what the diode can handle (known as VBR), something interesting happens at the atomic level. Impact ionization kicks off a chain reaction where electrons and holes multiply rapidly, creating a conductive path that basically short circuits the excess energy away in an instant. We're talking response times below one nanosecond here, which is why these components work so well against those pesky electrostatic discharges that rise up too quickly for other solutions. How accurate they are depends largely on how the manufacturer dopes the semiconductor material during production. This careful tuning lets engineers get VBR values within pretty narrow ranges, usually around plus or minus 5% to 10%. What makes TVS diodes stand out compared to alternatives like MOVs or gas discharge tubes? They don't depend on heat buildup or moving parts. Instead, they leverage those quantum phenomena happening inside solid state materials, giving them rock steady performance even when temperatures fluctuate or after years of operation.

Real-time clamping behavior during ESD and surge events

When activated, TVS diodes limit sudden voltage spikes to what's called the clamping voltage (VC), usually around 20 to 30 percent higher than the breakdown voltage (VBR). Take IEC 61000-4-2 ESD events for example those fast rising voltages with 5 nanosecond rise times. The diode starts clamping almost instantly, within that first nanosecond actually, so it stops dangerous peak voltages from getting to sensitive downstream integrated circuits. For longer lasting power surges like the 8/20 microsecond waveforms specified in IEC 61000-4-5 standards, these diodes handle massive current flows measured in thousands of amperes (IPP) safely diverting them to ground while keeping VC under levels that would damage connected components. There are two main types too bidirectional models work great for AC connections where polarity doesn't matter, whereas unidirectional versions give better performance in DC systems because they have lower forward voltage when clamping. What makes TVS diodes really useful though is their self-resetting nature. After whatever voltage spike passes through, they go back to their normal high resistance state all on their own, no need for any kind of manual resetting or dealing with latch-up issues that can plague other protection devices.

Key TVS Diode Parameters Every Engineer Must Understand

VRWM, VBR, VC, and IPP — translating datasheet specs into robust protection margins

Four parameters govern effective TVS selection and system-level reliability:

- VRWM (Reverse Standoff Voltage) must exceed the circuit’s maximum operating voltage—ideally by 10–15%—to avoid leakage or false triggering during normal operation.

- VBR (Breakdown Voltage) defines the onset of avalanche conduction; for optimal margin, it should be 1.2–1.5× VRWM.

- VC (Clamping Voltage) is the maximum voltage seen by downstream components during a specified IPP; it must remain safely below the minimum damage threshold of protected ICs.

- IPP (Peak Pulse Current) quantifies surge-handling capacity under standardized waveforms (e.g., 8/20 μs); higher values indicate greater energy absorption capability.

| Parameter | Design Margin Rule | Failure Risk if Ignored |

|---|---|---|

| VRWM | ≥ 110% of operating voltage | Leakage, false triggering, or premature conduction |

| VC | ≤ 85% of protected component’s absolute max rating | Catastrophic or latent failure of downstream ICs |

| IPP | ≥ 200% of expected worst-case surge current | Thermal runaway, bond-wire fusing, or catastrophic failure |

Engineers should apply a 20% derating to IPP for every 50°C rise above 25°C ambient and verify VBR tolerance across temperature to ensure consistent protection margins.

Capacitance considerations for high-speed interfaces (USB, HDMI, Ethernet)

Junction capacitance (CJ) directly impacts signal integrity on high-speed data lines. Even small amounts of added capacitance attenuate high-frequency content and distort edge rates—potentially causing bit errors or link failures. Target values are stringent:

- USB 3.2 Gen 2 (10 Gbps): ≤1.0 pF

- HDMI 2.1 (48 Gbps): ≤0.3 pF

- 10GbE Ethernet: ≤0.8 pF

The bidirectional TVS diodes naturally have higher capacitance compared to their unidirectional counterparts because they feature this dual junction design. When trying to cut down on those pesky parasitic effects, it makes sense to position low capacitance TVS components no more than about half an inch away from connectors or integrated circuit pads. Also important is making sure traces run wide and straight, at least 20 mils wide works well for most applications. Connecting the ground pad properly matters too. Tie it directly to a good solid reference plane using several vias instead of just one. This helps reduce inductive impedance which can actually make voltage overshoot problems worse if left unchecked.

TVS Diode Compliance and Performance in Standardized Threat Scenarios

Meeting IEC 61000-4-2 (ESD), -4-4 (EFT), and -4-5 (surge) requirements

TVS diodes are built to handle those tough immunity requirements and usually go beyond what's needed. When it comes to IEC 61000-4-2 standards, these components can handle those intense 30kV contact discharge ESD pulses really quickly, stopping them before they damage sensitive microcontrollers or interface ICs either right away or over time. They work great with those repeated EFT bursts too (as per IEC 61000-4-4 at frequencies around 5kHz to 100kHz). The fast recovery time combined with low dynamic resistance means these diodes can push away those multi-amp transient spikes from data lines without messing up communications. During high energy surge tests under IEC 61000-4-5 specs, properly certified TVS diodes can take hits of up to 6kV/3kA between line and ground connections while still keeping their performance stable without any major failures. Independent testing shows they work well across pretty extreme temperatures (-40°C all the way up to +125°C), meeting Class 4 immunity standards. Design engineers love how these parts consolidate protection into one reliable component instead of needing multiple layers of filters and other clamping devices. This simplification cuts down on parts needed for the bill of materials, makes certification easier, and generally leads to better reliability when products are actually deployed in the field.

Practical TVS Diode Selection and PCB Layout Best Practices

Bidirectional vs. unidirectional TVS diodes: matching polarity, grounding, and fault coverage

When deciding between bidirectional and unidirectional TVS diodes, engineers need to consider how signals are routed through the system and what kind of faults might occur. Bidirectional options work like having two avalanche diodes back-to-back, making them necessary for those AC coupled or floating connections we see in things like RS-485, HDMI, and Ethernet where voltage spikes can come from either direction. The unidirectional versions actually perform better at clamping voltages in DC circuits because they conduct electricity more efficiently when dealing with positive transients, plus they block current flow when there's a negative spike. Getting this wrong matters a lot though. Putting a unidirectional diode on a bidirectional communication line leaves gaps in protection against negative surges that could damage sensitive components downstream. Ground connection matters just as much here. Best practice involves running short, wide copper traces from the TVS cathode (or shared point in bidirectional models) straight to a solid ground plane with several thermal vias for stability. Bad grounding creates these annoying ground bounce issues that eat away at the effectiveness of surge protection, sometimes reducing it by nearly half according to various industry tests on transient behavior.

Optimal placement: minimizing trace inductance and maximizing protection efficacy

The way a PCB is laid out actually matters more for TVS performance than just looking at component specs. The diode should sit no further than about half a centimeter from the connector or protected IC pin. Every extra centimeter introduces roughly 10 nanohenries of series inductance, which can delay the clamping action and let dangerous voltage spikes happen during ESD events. When routing traces, go for straight lines and keep them wide (at least 20 mil) while avoiding those right angle bends that create impedance problems. For high speed interfaces, position the TVS as close as possible next to the connector itself. Connect the ground pad directly to the reference plane using three or more evenly spaced vias. This creates a good low inductance return path that sends over 90 percent of surge current away from delicate circuitry. Real world tests following IEC 61000-4-2 standards have shown these layout techniques cut down transient exposure times by around half when compared to older methods with daisy chained grounds or those pesky long stub connections.