Understanding High Voltage Capacitor Core Requirements

Voltage Rating and Dielectric Strength

The primary consideration in selecting capacitors for high-voltage applications is voltage rating. A capacitor’s voltage rating must exceed the maximum operating voltage of the target circuit by a safe margin to prevent dielectric breakdown. This margin is especially critical in scenarios like industrial automation inverters and new energy systems where voltage fluctuations are common. High-quality capacitors designed for high-voltage use feature robust dielectric materials that maintain stability even under prolonged high-voltage stress, ensuring reliable performance and long service life.

Temperature Stability and Environmental Resistance

High-voltage applications often operate in harsh environments, making temperature stability a key factor for capacitors. Industrial-grade and automotive-grade capacitors must withstand wide temperature ranges from extreme cold to high heat without compromising their capacitance values or insulation properties. For example, capacitors used in automotive electronics need to endure rapid temperature changes under the vehicle hood, while those in photovoltaic inverters must resist UV radiation and humidity. Choosing a capacitor with excellent temperature coefficient and environmental sealing can significantly reduce the risk of failure in high-voltage systems.

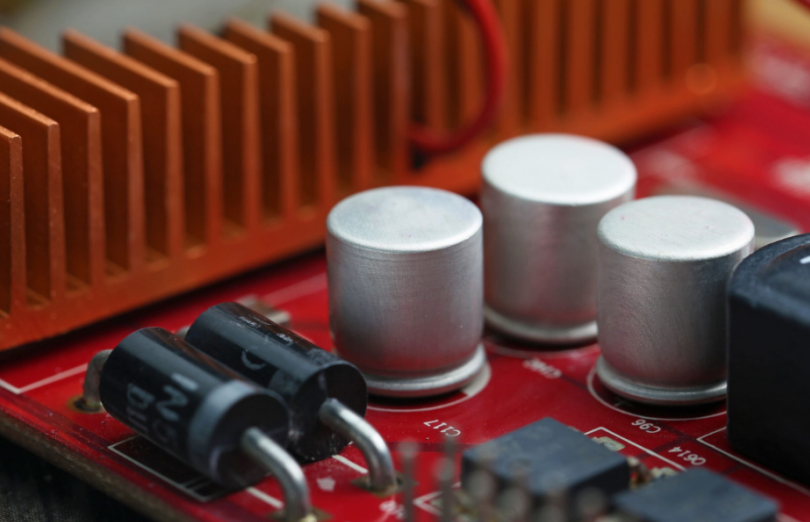

Key Capacitor Types for High Voltage Scenarios

MLCCs for Compact High Voltage Designs

Multilayer Ceramic Capacitors, or MLCCs, are ideal for high-voltage applications that demand compact size and high capacitance density. The latest innovation in this category comes from Taiyo Yuden, which has mass-produced the world’s first 1005-sized 22μF embedded MLCC. This capacitor is tailored for power decoupling in AI servers and high-performance information devices, proving that MLCCs can meet the high-voltage and miniaturization needs of advanced electronic systems. When selecting MLCCs for high-voltage use, it is essential to verify their voltage tolerance and ripple current handling capabilities to match the application’s requirements.

Film Capacitors for New Energy and Industrial Inverters

Film capacitors stand out in high-voltage new energy systems, industrial inverters and other engineering applications. Their superior dielectric strength and low loss characteristics make them suitable for high-frequency and high-power high-voltage circuits. In photovoltaic inverters and energy storage systems, film capacitors can effectively handle large voltage swings and high current loads, ensuring stable energy conversion. For engineers working on new energy projects, film capacitors are a reliable choice that balances performance and durability in high-voltage environments.

Critical Selection Criteria for Reliable Performance

Application Specific Grade Considerations

Different high-voltage applications require capacitors of specific grades. Military-grade capacitors are designed for the most demanding conditions, such as aerospace and defense systems, where reliability is non-negotiable. Automotive-grade capacitors must comply with strict industry standards like IATF 16949:2016 to ensure they can withstand the harsh operating conditions of vehicles. Industrial-grade capacitors are optimized for use in factory automation equipment, PLC protection systems and motor drives, providing stable performance even in continuous operation scenarios. Matching the capacitor grade to the application’s specific requirements is a fundamental step in the selection process.

Inventory and Sourcing Reliability

For high-voltage projects with tight deadlines, access to in-stock capacitors is crucial. A reliable distributor with a robust global sourcing network can ensure timely delivery of the required capacitors, avoiding project delays caused by component shortages. Additionally, distributors that offer model matching and substitution services can help customers find alternative capacitors when their preferred models are out of stock, ensuring a worry-free supply chain for high-voltage applications.

Partnering with a Trusted Distributor for High Voltage Capacitor Sourcing

Jaron’s Brand Authorization and Global Sourcing Capabilities

Jaron, a Shenzhen-based international distributor, is a trusted partner for sourcing high-voltage capacitors and other electronic components. As an authorized distributor of top global brands including ADI, TI, NXP, Xilinx, Samsung and Micron, Jaron provides genuine and high-quality capacitors that meet the strict standards of high-voltage applications. The company specializes in military-grade, automotive-grade and industrial-grade components, along with connectors, leveraging its strong global sourcing capabilities to meet diverse customer needs. With over 500 million units shipped yearly and serving more than 1,000 global clients, Jaron has established a proven track record in reliable component distribution.

Flexible Payment and Supply Chain Solutions

Jaron offers flexible payment options to facilitate seamless transactions for customers worldwide. It supports USD payments in both Mainland China and Hong Kong, along with other currencies like USDT and THB, catering to the diverse financial needs of global clients. The company’s localized expertise combined with its global distribution network ensures tailored supply chain solutions for every market. Whether customers need spot orders or futures bookings, Jaron can provide efficient and reliable services, helping them optimize their high-voltage application projects with the right capacitors and components.

Conclusion

Choosing the right capacitors for high-voltage applications requires a comprehensive understanding of core requirements, key capacitor types and critical selection criteria. By partnering with a trusted distributor like Jaron, engineers and project managers can access a wide range of high-quality capacitors, benefit from professional sourcing support and ensure the reliability of their high-voltage systems. As high-voltage applications continue to evolve in industries such as new energy, automotive electronics and industrial automation, selecting the appropriate capacitor will remain a vital step in driving innovation and ensuring system performance.