Understanding MOSFETs and Their Role in Power Management

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) form the foundation of modern power management systems, enabling precise control over energy flow in applications ranging from renewable energy inverters to electric vehicle charging stations. Their ability to switch rapidly with minimal losses makes them indispensable for balancing efficiency, thermal performance, and system reliability.

Why Power MOSFETs Are Critical for Modern Power Systems

Industrial DC-DC converters and motor drives rely heavily on Power MOSFETs for switching because these components work really well at frequencies ranging from around 100 kHz all the way up to about 1 MHz. Compared to old school mechanical relays or those bipolar transistors, MOSFETs just keep going strong even when temperatures swing wildly between -55 degrees Celsius and as high as 175 degrees Celsius. Plus, they cut down on conduction losses somewhere in the neighborhood of 40 percent. Their ability to withstand such extremes makes them absolutely essential for large scale battery storage systems. When power needs spike during peak times, these little workhorses manage energy discharge with something close to 99 point two percent accuracy, which matters a lot when dealing with massive grids.

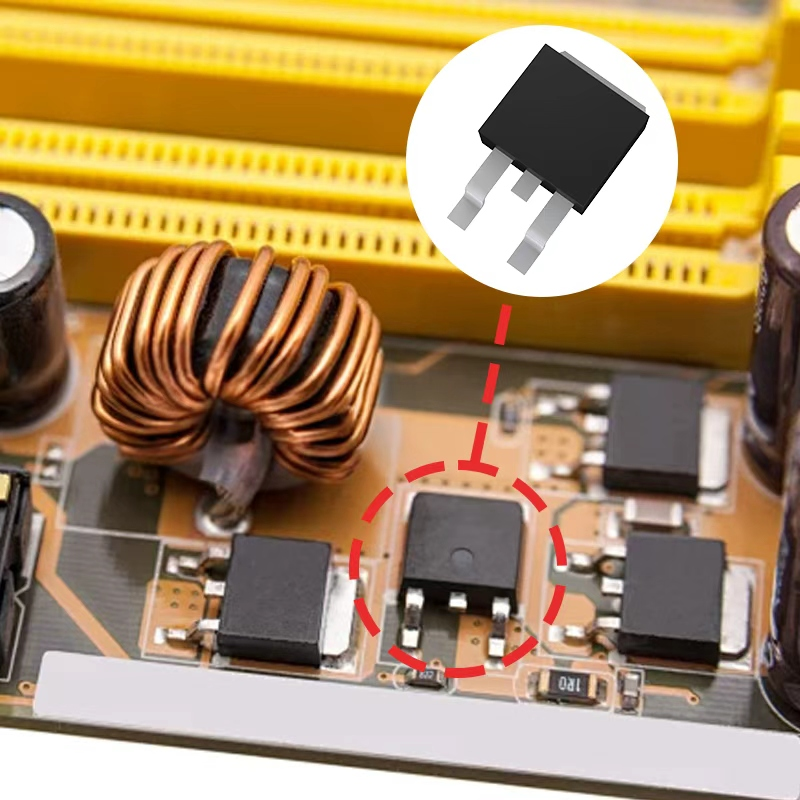

Fundamentals of MOSFET Operation and Structure

The basic structure of a MOSFET includes three main parts: the gate which controls how conductive it becomes, the drain where current comes out, and the source where current goes in. When we apply voltage to the gate terminal, it generates an electric field that actually creates a path for electricity to travel between the drain and source terminals. This is what lets current flow through the device. Most high power applications use N-channel enhancement mode MOSFETs because they have really low resistance when turned on. Some models can get down to around 1 milliohm of resistance, which means these components waste much less energy compared to other types during operation.

| Parameter | Silicon MOSFET | SiC MOSFET | GaN MOSFET |

|---|---|---|---|

| Switching Speed | 100–500 kHz | 1–5 MHz | 10–50 MHz |

| Max Voltage | 900 V | 1,700 V | 650 V |

| Thermal Limit | 175°C | 200°C | 150°C |

Efficient Switching Performance Under Dynamic Load Conditions

Advanced MOSFETs adapt to load fluctuations through adaptive gate drivers and temperature-compensated Rdson. In server power supplies using paralleled stages, efficiencies reach 94% even when loads shift from 10% to 100% within microseconds. This responsiveness prevents voltage spikes in automotive traction inverters, ensuring millisecond-level adjustments without exceeding thermal limits.

Maximizing Switching Efficiency in MOSFET Circuits

Core principles of switching efficiency

Switching efficiency depends on minimizing energy losses during state transitions. Key factors include rise/fall times, gate charge, and body diode reverse recovery. Optimal operation balances switching speed with thermal stress—faster transitions reduce switching losses but increase electromagnetic interference (EMI).

High-frequency switching capabilities and EMI trade-offs

Modern MOSFETs exceed 1 MHz in DC-DC converters and motor drives. While high-frequency operation improves power density, it amplifies EMI due to parasitic capacitance and inductance. Proper PCB layout and snubber circuits mitigate these effects without sacrificing efficiency.

Reducing conduction losses through low on-resistance (Rdson)

Conduction losses scale with I²R, making Rdson reduction essential—state-of-the-art devices achieve values below 1 mΩ. Advanced packaging like DirectFET® and copper clip bonding enhances current capacity while maintaining low thermal resistance.

Strategies for minimizing power loss in switching stages

- Zero-voltage switching (ZVS): Synchronizes voltage and current transitions to eliminate overlap losses

- Gate driver optimization: Matches drive current to gate charge requirements

- Paralleling devices: Distributes thermal load across multiple MOSFETs

- Adaptive dead-time control: Prevents shoot-through currents in bridge configurations

These techniques reduce total power loss by up to 30% in industrial motor drives (Power Systems Journal, 2023), highlighting the importance of MOSFET optimization in energy-efficient systems.

Thermal Management and Conduction Loss Optimization

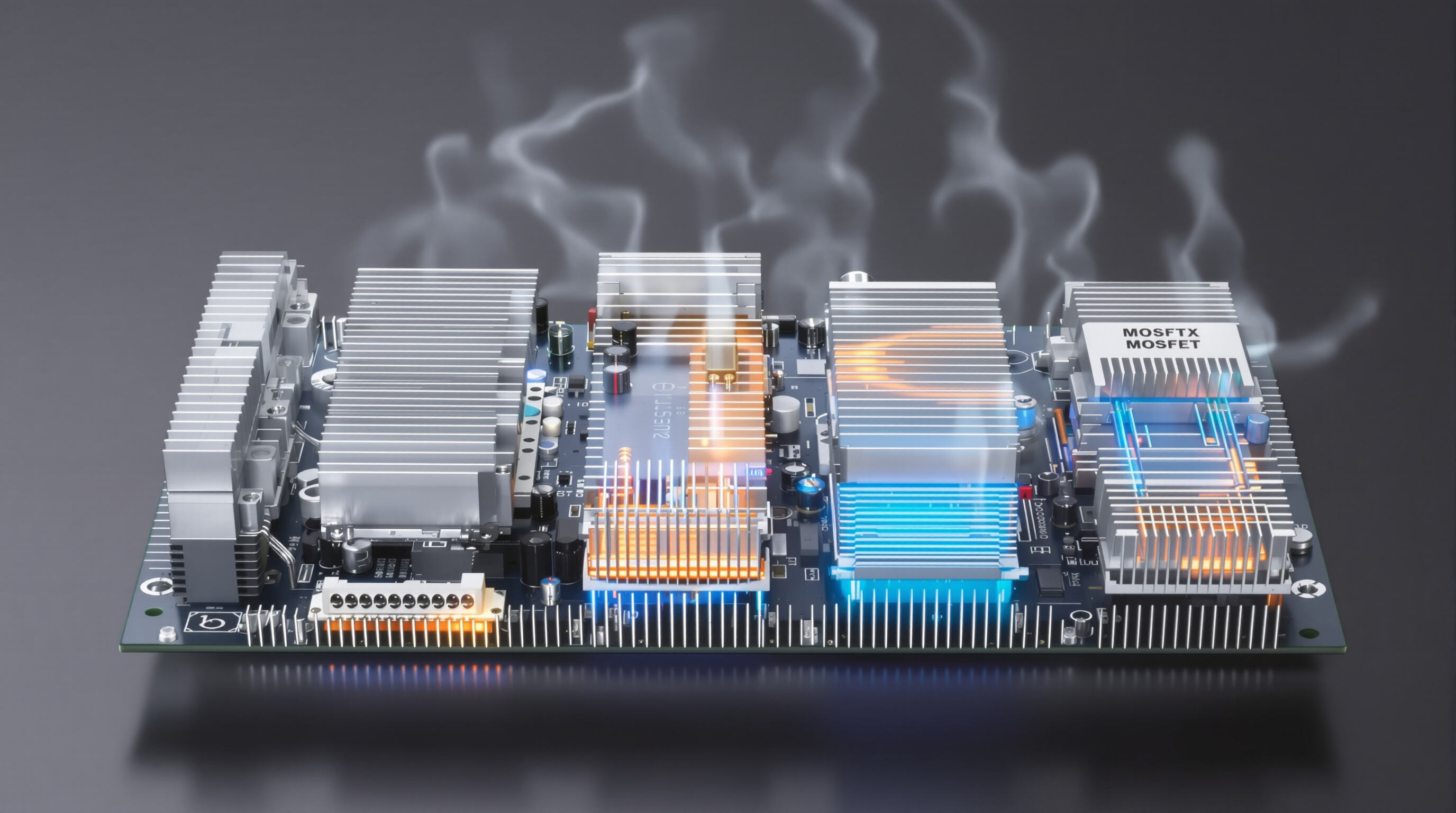

MOSFETs convert electrical energy efficiently, but even small conduction losses accumulate as heat during continuous operation. Each 10°C rise above optimal temperature can halve component lifespan (Applied Thermal Engineering 2022). Effective thermal management must therefore balance electrical performance with robust heat dissipation.

Impact of conduction losses on thermal performance

When MOSFETs have an RDS(on) rating under 2 milliohms, they cut down conduction losses by around 60 percent, which means much cooler operating temperatures at the junction points. But even so, systems handling currents above 100 amps continue to struggle with heat management issues. Research from A. Li and colleagues back in 2022 showed that without proper cooling solutions, hotspots in car inverters can hit scorching temperatures of 145 degrees Celsius during operation. This kind of extreme temperature difference across components leads to real mechanical problems over time. The stress builds up gradually, causing various failure points in the device, especially noticeable when looking at wire bonds that start to degrade faster than expected under these conditions.

Effective thermal management in high-power MOSFET applications

Advanced cooling strategies combine multiple approaches:

| Technique | Efficiency Gain | Implementation Complexity |

|---|---|---|

| Liquid cooling plates | 50-70% | High |

| Aluminum heat sinks | 20-40% | Low |

| Thermal interface materials | 10-30% | Moderate |

In industrial motor drives, optimized layouts improve airflow by 35% while reducing component density. Recent EV battery studies demonstrate 25°C temperature reductions using phase-change materials in power modules (Energy Conversion and Management: X 2024). When paired with real-time monitoring, these methods prevent thermal runaway in 98% of fault scenarios.

Wide-Bandgap Semiconductors: SiC and GaN vs. Silicon MOSFETs

Introduction to SiC and GaN MOSFET Technologies

Silicon carbide (SiC) and gallium nitride (GaN) leverage wider bandgaps (3.26 eV and 3.4 eV) compared to silicon's 1.1 eV, enabling higher breakdown voltages and electron mobility over 2000 cm²/Vs (Nature 2024). These properties support reliable operation above 200°C and switching frequencies beyond 1 MHz, reducing transition losses by 70% versus silicon counterparts.

Performance Comparison: Efficiency, Speed, and Thermal Behavior

When operating at 650 volts, silicon carbide MOSFETs cut down conduction losses by about half compared to traditional silicon components. Meanwhile gallium nitride hits an impressive 98% efficiency mark when running at frequencies around 2 megahertz. According to research published in 2024 on semiconductors, the better heat transfer properties of SiC (with thermal conductivity rating at 490 watts per meter Kelvin) means electric vehicle inverters can be made roughly 40% smaller than before. On the flip side, GaN really shines in those high frequency scenarios we see in modern 5G network equipment. What these advances mean for engineers is significant too since both materials slash the weight needed for cooling systems by three to five times what standard silicon solutions require.

Cost vs. Efficiency: Evaluating Adoption in Industrial Applications

Despite their initial price tag being roughly double what traditional options cost, silicon carbide and gallium nitride MOSFETs actually save money when looking at the whole system picture. Take solar farms for instance - those switching to SiC inverters typically see about four percent boost in energy production, which means getting their investment back in just over two or three years depending on conditions. Meanwhile, data centers have found that servers equipped with GaN power supplies slash cooling expenses somewhere around fifteen dollars per kilowatt every year. Many companies are adopting hybrid solutions these days too, combining standard silicon IGBT technology with these newer wide band gap components specifically where performance matters most while keeping overall costs reasonable across the board.

Real-World Applications of MOSFETs in Energy and Mobility

MOSFETs in Renewable Energy Systems: Solar Inverters and BESS

MOSFET technology really boosts how efficiently energy gets converted in both solar inverters and battery energy storage systems (BESS), mainly because they cut down on those pesky switching losses. The speed at which these devices switch makes maximum power point tracking (MPPT) much more accurate too, which means solar panels can actually capture around 12% more sunlight throughout the day. When it comes to BESS applications, MOSFETs handle power flowing both ways pretty well, keeping voltage drops below 2% most of the time, something that helps maintain grid stability when integrating renewable sources. A recent market report from 2023 showed that about a quarter of all major components used in large scale solar installations are power MOSFETs, highlighting just how important they've become for building out our green energy infrastructure going forward.

Power Management in Electric Vehicles and Charging Infrastructure

Electric vehicles rely on MOSFET technology to handle the intense currents needed for battery charging and powering motors, with some systems reaching nearly 98% efficiency when converting DC to AC power. One key factor here is something called Rdson - lower values mean less energy gets lost as heat during operation. This becomes really important in those high voltage 800V systems used in modern EVs, where even small improvements can extend driving range by around 15%. When looking at fast charging infrastructure, engineers often stack multiple MOSFETs together to push out massive 350 kW charges while still managing to keep component temperatures below critical levels like 125 degrees Celsius. That's what makes those super quick 10 minute top-ups possible. According to recent reports from the US Department of Energy, if we continue adopting these kinds of technological improvements across the board, we might see transportation sector emissions drop by an incredible 340 million tons each year by the time we reach 2030.

Case Study: Advancing Efficiency in Server Power Supplies

A hyperscale data center replaced legacy IGBTs with silicon carbide (SiC) MOSFETs in its 2.4 MW power distribution units. The upgrade reduced switching losses by 37%, lowered cooling costs by $18,000 per rack annually, and improved power usage effectiveness (PUE) by 22%, demonstrating MOSFETs' impact in high-density computing environments.

Frequently Asked Questions

What are the main applications of MOSFETs in power management?

MOSFETs are widely used in renewable energy systems, electric vehicles, motor drives, and server power supplies for efficient power conversion and management.

How do MOSFETs improve the efficiency of power systems?

MOSFETs offer rapid switching capabilities with minimal energy losses, which significantly enhances the efficiency of power systems by reducing conduction and switching losses.

What is the significance of SiC and GaN technologies in MOSFET applications?

SiC and GaN technologies provide higher switching speeds, better thermal conductivity, and higher efficiency than traditional silicon MOSFETs, making them suitable for high-performance applications.

How do thermal management techniques benefit MOSFET operation?

Effective thermal management extends MOSFET lifespan by managing heat dissipation through strategies such as liquid cooling, heat sinks, and phase-change materials.

Table of Contents

- Understanding MOSFETs and Their Role in Power Management

- Maximizing Switching Efficiency in MOSFET Circuits

- Core principles of switching efficiency

- High-frequency switching capabilities and EMI trade-offs

- Reducing conduction losses through low on-resistance (Rdson)

- Strategies for minimizing power loss in switching stages

- Thermal Management and Conduction Loss Optimization

- Wide-Bandgap Semiconductors: SiC and GaN vs. Silicon MOSFETs

- Real-World Applications of MOSFETs in Energy and Mobility

- Frequently Asked Questions