How Gas Discharge Tubes Work: Core Principles and Components

Gas discharge tubes, commonly called GDTs, work to safeguard delicate electronic components through the process of ionizing inert gases when subjected to high voltage conditions. Normally, these devices contain gases such as neon or argon that act as insulation between metal contacts inside the tube. The real action happens when there's a sudden spike in electrical potential that goes beyond what the device can handle. These spikes often come from lightning strikes or power grid fluctuations where voltages rise rapidly, sometimes exceeding 90 volts per microsecond. At this point, electrons within the gas start moving faster and faster until they actually knock electrons off gas atoms, which creates this glowing plasma pathway almost instantly. What we see then is the GDT changing from something that blocks current flow completely to basically a short circuit that sends all that dangerous excess electricity harmlessly into the earth instead of damaging whatever equipment it was meant to protect.

The Fundamental Physics Behind Gas Discharge Tube Operation

The process starts when free electrons begin moving through an electric field according to what's known as Townsend discharge theory. These electrons speed up and bump into neutral gas molecules, which causes them to release even more electrons. What happens next is pretty interesting - there's this chain reaction where each collision creates more electrons, and suddenly we see a big jump in how conductive everything becomes. When things get really intense and the current hits around 1 kiloamp per square centimeter mark, something dramatic occurs. The device shifts into what engineers call arc mode. At this point, a stable plasma forms inside the tube, and it actually keeps the voltage from going too high, usually holding it under about 50 volts across the whole thing.

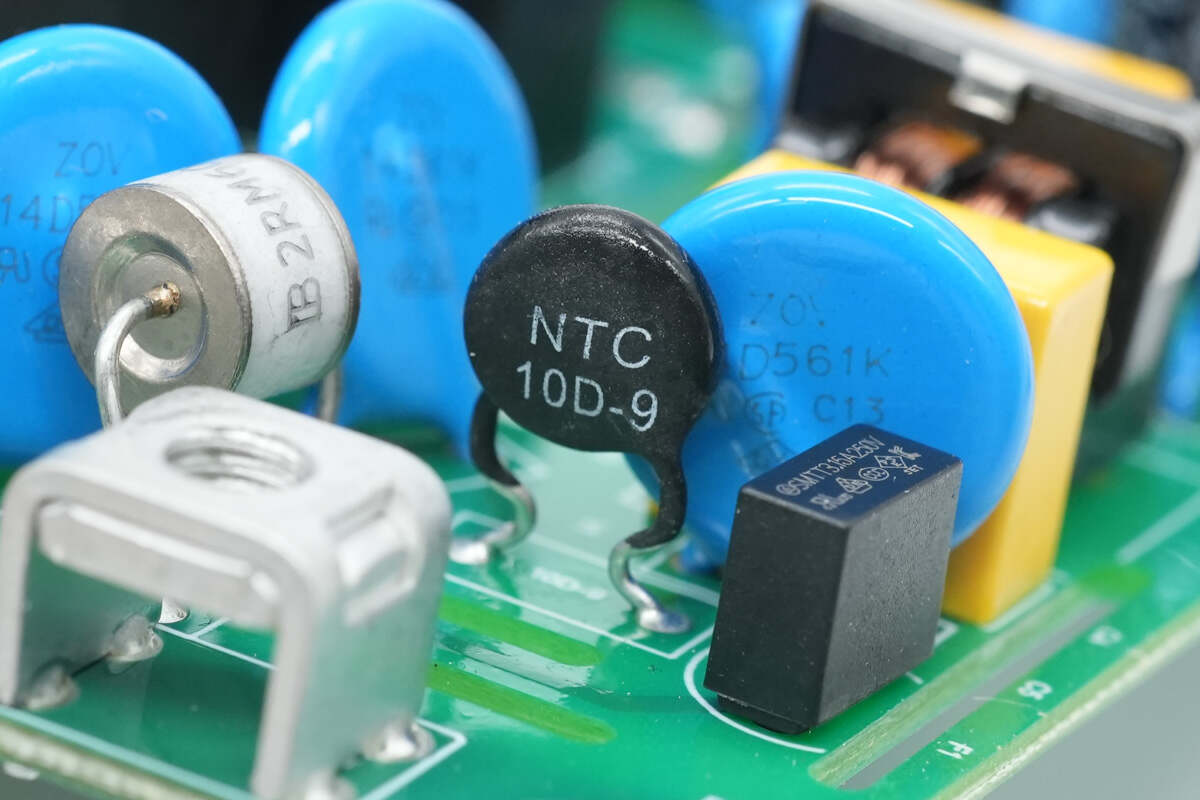

Key Components: Electrodes, Inert Gas, and Ceramic Housing

- Electrodes: Made from tungsten or nickel-iron alloys, these withstand arc-induced temperatures up to 3,000°C

- Gas Mixtures: Blends of neon and argon are engineered to achieve specific DC breakdown voltages (200–1,000V) and reliable extinction characteristics

- Ceramic Enclosures: Alumina-based housings provide up to 15 kV isolation, preventing external arcing and ensuring mechanical stability

Breakdown Mechanisms and the Role of Dielectric Strength

The dielectric strength of inert gases—typically 20–40 kV/cm—determines the GDT’s triggering voltage. Rapid transients create non-uniform electric fields across the electrode gap, promoting field emission even below nominal breakdown levels. Precise control of gap distance (within ±0.05 mm) ensures consistent performance across manufacturing batches.

Ionization Stages: From Townsend Discharge to Arc Formation

- Townsend Phase: At low pressure (~10–100 µTorr), µA-level currents initiate electron cascades

- Glow Discharge: As ionization spreads, mA-range currents produce visible purple luminescence across the gap

- Arc Transition: Thermal ionization generates plasma at 5,000–10,000 K, enabling the GDT to handle kA-level surge currents

This staged process allows response times under 100 ns, making GDTs highly effective for high-energy transients where semiconductor devices may fail.

Role of GDTs in Overvoltage and Surge Protection Systems

GDTs as Primary Defenders Against Transient Overvoltage Events

Gas discharge tubes serve as primary protection against surges, kicking in within millionths of a second to create a conductive path to earth whenever voltage spikes happen. These devices work by shorting out excessive current flows above 20 thousand amps before they can damage anything connected downstream. What makes them so effective is their ability to handle massive energy bursts through ionization processes, capable of absorbing around ten kilojoules during each incident. This capacity matters a lot for installations facing frequent electrical stress, think about power distribution centers or telephone exchange facilities where regular maintenance checks are part of daily operations.

Clamping Voltage Dynamics and Energy Dissipation During Surges

When they start conducting, Gas Discharge Tubes (GDTs) hold onto a clamping voltage somewhere between 20 and 50 volts no matter how big the surge gets because their plasma remains stable. The reason behind this reliable performance? Well, it all comes down to those carefully balanced gas mixtures inside them. Most often we see around 90 percent neon mixed with about 10 percent argon. This combination works pretty well for getting that right balance between strong insulation properties and good ionization characteristics. Now when talking about energy handling capacity, some really solid designs can actually handle over 1,000 joules per microsecond worth of energy dissipation. And guess what keeps everything from overheating? Those special ceramic enclosures that resist heat buildup quite effectively.

Coordination with Secondary Protectors Like TVS Diodes in Hybrid Circuits

Modern hybrid protection circuits typically combine gas discharge tubes (GDTs) with transient voltage suppression (TVS) diodes for better performance. Basically, the GDT takes care of the big stuff first, handling those large surges of current that can range from around 5 to even 100 kiloamperes. Then the TVS diodes kick in downstream to knock down whatever small voltage spikes remain, bringing them down to something safe, usually under 500 volts. When these two components work together in layers like this, they cut down on the amount of energy that actually gets through by somewhere between 40 and maybe 60 percent compared to just using one type of protector alone. This kind of setup is what most manufacturers need to meet those FCC requirements for protecting sensitive equipment installations.

Case Study: GDT Use in Telecom Line and PoE Surge Protection

Tests conducted on Brazil's telecom network in 2023 showed something pretty impressive about GDT arrays. They cut down on power surge problems by around 78%, which is quite a drop. At the same time, these devices kept signals running strong at speeds up to 2.5 Gbps. When it comes to Power over Ethernet systems, combining GDTs with TVS components worked really well too. These setups managed to bring down those massive 6kV surges all the way to just 57 volts peak, and no data got lost during this process. Even better, everything continued working fine when there was constant 48 volts DC flowing through the system. What we see here is how versatile GDT technology actually is for different kinds of electrical applications, whether dealing with alternating current or smaller direct current flows.

Tables are intentionally omitted as they wouldn’t enhance clarity for this specific technical content.

Performance Characteristics: Response Time, Sparkover, and Reliability

Response Time Analysis: Nanosecond vs. Microsecond-Scale Activation

Gas discharge tubes typically react between 5 to 500 nanoseconds, though this varies based on how quickly surges rise and their overall strength. When dealing with those really fast voltage spikes above 1 kV per microsecond, most studies show around 97% of GDTs will fire off within just 100 nanoseconds. A recent paper from IEEE in 2023 actually found they beat out MOV type protectors when lightning strikes happen suddenly. For slower situations where voltages creep up over time but stay below what would normally break them down, these devices take longer to activate as ions slowly multiply throughout the gas inside the tube.

Factors Affecting Sparkover Voltage: Gas Mixture, Pressure, and Design

The sparkover voltage in standard gas discharge tubes actually fluctuates quite a bit, usually within about plus or minus 15%, because of how ions behave inside them. When it comes to gas mixtures, neon and argon combinations tend to start conducting electricity at roughly 90 volts direct current. But if we switch to hydrogen based gases, things get much trickier since they need way higher voltages, somewhere around 500 volts before breaking down. To keep these gases pure enough for proper operation, manufacturers rely on advanced ceramic metal seals that can hold contamination levels below 50 parts per million. These seals also help maintain stable internal pressures ranging from 200 to 400 millibar. Another important design consideration is electrode shape. Radial designs significantly cut down on electric field distortions compared with flat ones, which makes a big difference. This improvement allows for much tighter voltage control, down to plus or minus 5%, something critical when making components for sensitive medical equipment where precision matters most.

Statistical Variation in DC Sparkover and Advancements in Precision-Tuned GDTs

The DC sparkover voltage tends to follow what's called a Weibull distribution pattern. What we see happening is that the variation gets worse over time too. After about 100 million surge cycles, the deviation jumps from around 8% all the way up to 22% in standard designs. But there's been some exciting progress recently. Back in 2022, engineers started using these laser trimmed electrodes which made things much more stable. These new components cut down on parameter drift by nearly two thirds! They've managed to get really consistent results with just 1.2 volts standard deviation throughout the entire temperature spectrum from minus 55 degrees Celsius right up to plus 125 degrees. And this level of precision makes a big difference practically speaking. Engineers can now stack components in series for those high voltage systems such as 1500 volt solar panel installations without needing those extra balancing resistors that used to be necessary.

Let-Through Energy and Follow Current Challenges in AC Power Systems

When dealing with AC systems, gas discharge tubes (GDTs) typically encounter follow-on currents ranging between 0.5 and 2 amps after surges have been dissipated. Without proper protection through current limiting fuses, these residual currents can cause serious heat buildup issues over time. Studies indicate that simply doubling the arc gap size from 1.5mm to 3mm cuts down on let through energy by around 72 percent during those intense 10kA 8/20 microsecond events we often see. The latest designs incorporate innovative quenching chambers with spiral shaped gas pathways that manage to snuff out electrical arcs within just under 5 milliseconds. This performance meets all the standards set forth in IEC 61643-11 for Class I components, making them suitable for demanding industrial applications where reliability is paramount.

Comparative Analysis: GDTs vs. MOVs and TVS Diodes in Real-World Applications

Advantages and Limitations of GDTs Compared to MOVs and TVS Diodes

When it comes to handling those big energy surges, gas discharge tubes really stand out. They can take on currents as high as 100 kiloamperes, which puts them way ahead of MOVs that typically handle between 40 and 70 kA, and definitely beats TVS diodes which max out around 1 to 5 kA. Now, GDTs do have one downside compared to TVS diodes since they kick in slower, taking anywhere from 100 to 500 nanoseconds versus the sub-nanosecond response time of TVS devices. But when we compare them side by side with MOVs, GDTs actually hold their own in terms of reaction speed. What makes GDTs truly valuable for many applications though is how long they last. These components can survive well over 100 surge events before showing signs of wear, while most MOVs start to break down after only about 10 to 20 surges because their materials simply get tired from all that stress.

| Device | Response Time | Surge Capacity | Lifetime (Surges) | Best Use Case |

|---|---|---|---|---|

| GDT | 100–500 ns | Up to 100 kA | 100+ | Telecom base stations |

| MOV | 50–200 ns | 40–70 kA | 10–20 | Consumer power strips |

| TVS | <1 ns | 1–5 kA | 1,000+ | Ethernet ports, IC protection |

Application in Power Substations, RF Antennas, and High-Speed Data Lines

Failure Mode Analysis: Wear-Out Mechanisms After Repeated Surge Events

Gas discharge tubes tend to break down mainly because their electrodes wear away over time from constant arcing or get contaminated by gases released from organic materials. Looking at field reports from last year, about 8 out of 10 failed devices showed clear signs of electrode damage after surviving around 150 lightning hits. The good news is that when fuses were properly installed, they stopped major failures in nearly all instances, with stats showing this worked for 92% of the cases studied. On the other hand, metal oxide varistors don't just fail suddenly but rather slowly deteriorate as tiny cracks form in their zinc oxide components whenever they experience repeated heat cycles. This gradual degradation makes them different from GDTs in how they ultimately malfunction.

Controversy: Are GDTs Too Slow for Modern High-Speed Communication Systems?

TVS diodes are pretty much the go-to solution for protecting those super fast interfaces such as USB4 and 25G Ethernet because they react within picoseconds. But guess what? Gas discharge tubes still have their place in mixed systems. When designers pair these TVS diodes that tackle those initial electrostatic shocks with gas discharge tubes handling the bigger energy surges, they end up with something really solid and budget friendly. The numbers back this up too. In tests on 10 Gbps fiber optic setups, this combination approach cut down overall expenses by around 40% when compared to going full throttle with just TVS components. Sure there's extra work involved in designing these hybrid systems, but the savings make it worth the trouble for many manufacturers out there.

FAQ

What is the primary purpose of Gas Discharge Tubes (GDTs)?

GDTs primarily serve to protect electronic components from high voltage surges by ionizing inert gases, which deflect excess electricity away from sensitive devices.

How do GDTs differ from MOVs and TVS diodes?

While GDTs can handle larger surge capacities, MOVs and TVS diodes respond more rapidly. GDTs are durable over many surge events, whereas MOVs may degrade faster but respond quicker to surges.

Can GDTs be used in combination with other protection devices?

Yes, GDTs can be combined with transient voltage suppression (TVS) diodes in hybrid protection circuits to better manage different parts of a voltage surge.

Why are GDTs preferred in telecom and power distribution facilities?

GDTs are favored in such facilities due to their high energy handling capability and durability, which are essential for locations facing frequent electrical stress.

Are GDTs suitable for modern high-speed communication systems?

Despite slower response times, GDTs can be used in conjunction with TVS diodes in mixed systems to provide cost-effective and reliable protection for high-speed communication applications.

Table of Contents

- How Gas Discharge Tubes Work: Core Principles and Components

- Role of GDTs in Overvoltage and Surge Protection Systems

- GDTs as Primary Defenders Against Transient Overvoltage Events

- Clamping Voltage Dynamics and Energy Dissipation During Surges

- Coordination with Secondary Protectors Like TVS Diodes in Hybrid Circuits

- Case Study: GDT Use in Telecom Line and PoE Surge Protection

- Performance Characteristics: Response Time, Sparkover, and Reliability

- Comparative Analysis: GDTs vs. MOVs and TVS Diodes in Real-World Applications

- FAQ