Learn what Electrostatic Discharge (ESD) is, how it causes permanent damage to ICs and electronic components, and how to apply environmental control, protection design, and cost-effective strategies to enhance ESD resistance.

1. The Hazards of Electrostatic Discharge

Electrostatic Discharge (ESD) is a primary cause of Electrical Overstress (EOS) damage in most electronic components or systems.

It can cause permanent damage to semiconductors, computer systems, and integrated circuits (ICs), leading to malfunction or total failure of electronic devices.

Such failures typically occur without warning and often originate from static charges accumulated on humans, equipment, or materials during manufacturing, testing, or handling.

2. Sources and Classifications of ESD

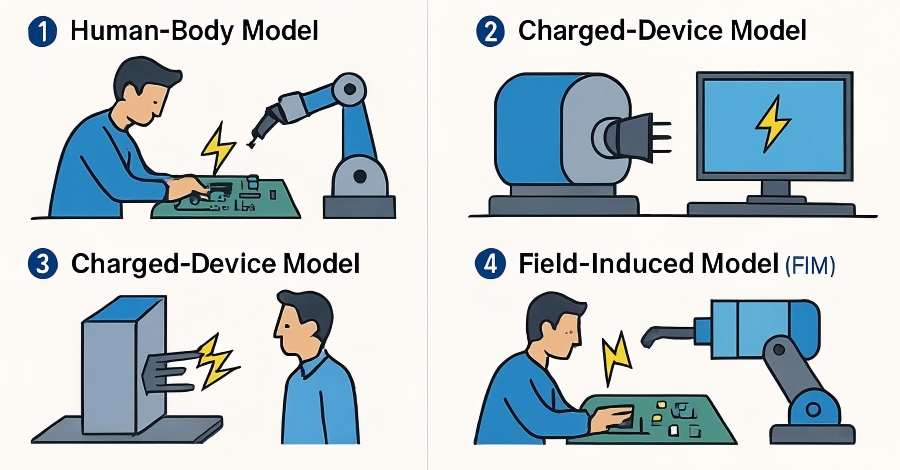

Based on discharge mechanisms, ESD is mainly categorized into four types:

Human-Body Model, HBM: Simulates the discharge from a human body to a sensitive component; the most common model.

Machine Model, MM: Represents discharges from machines or tools; characterized by higher current and greater risk.

Charged-Device Model, CDM: Describes the discharge that occurs when a charged device contacts a conductive surface.

Field-Induced Model, FIM: Simulates discharge caused by induced static fields, often occurring during automated handling.

3. Protection Strategies and Design Considerations

Environmental and Personnel Control: Anti-static flooring and workstations. Ionizers and humidity control. Personnel wearing wrist straps, anti-static clothing, and footwear,

Internal Circuit Protection: Use of protection devices such as TVS diodes, MOVs, etc. Select devices based on response time, clamping voltage, and energy tolerance. Enhance ESD robustness at the IC design level

Balancing Cost and Effectiveness: Modular design and standardized selection optimize cost-effectiveness.Suitable for economical deployment in mass production environments

4. Conclusion

Though invisible, ESD poses a significant risk in the electronics industry.

Only by implementing comprehensive ESD controls from design through production can product quality and reliability be ensured.