This article examines practical applications and performance advantages of MOSFETs in industrial CNCs and motor drives, including packaging, integration, and AI-driven evolution

I. Industry Demands and Technology Drivers

Industrial manufacturing and intelligent equipment require increasingly efficient and fast-switching drivers.

MOSFETs, with low gate charge and fast transition, have become the preferred choice in VFDs and high-frequency drives.

Compared to BJTs or IGBTs, MOSFETs offer lower switching losses and higher efficiency, especially in high-frequency, low-voltage industrial control applications.

II. Typical Application Scenarios

MOSFETs are widely used in CNC machines, automated production lines, AGVs, and robotic drives, where their high-frequency switching significantly boosts dynamic system performance.

In industrial IoT nodes and sensor power distribution, MOSFETs offer low-drop switching that improves heat management.

In PLC-controlled multi-axis drives, MOSFETs deliver microsecond-level PWM control with high current feedback sensitivity.

Moreover, in welding controllers, battery management systems, and servo drives, MOSFETs provide reliable switching for pulse current regulation and multi-channel power management.

III. Performance Advantages and Expanded Integration

MOSFETs can be paralleled with gate drivers for thermal and current balancing, supporting high-current, high-power applications.

Their low RDS(on) and fast switching enable partial replacement of IGBTs in high-power inverters.

In power conversion systems, MOSFETs reduce EMI interference, improve signal integrity, and allow for smaller filter sizes.

Multiple MOSFETs configured in H-bridge or half-bridge topologies enable synchronous rectification, efficient driving, and reverse current switching.

These configurations are widely implemented in electric tools, scooters, and forklifts, demonstrating mature applicability.

IV. Thermal Management and Packaging Strategies

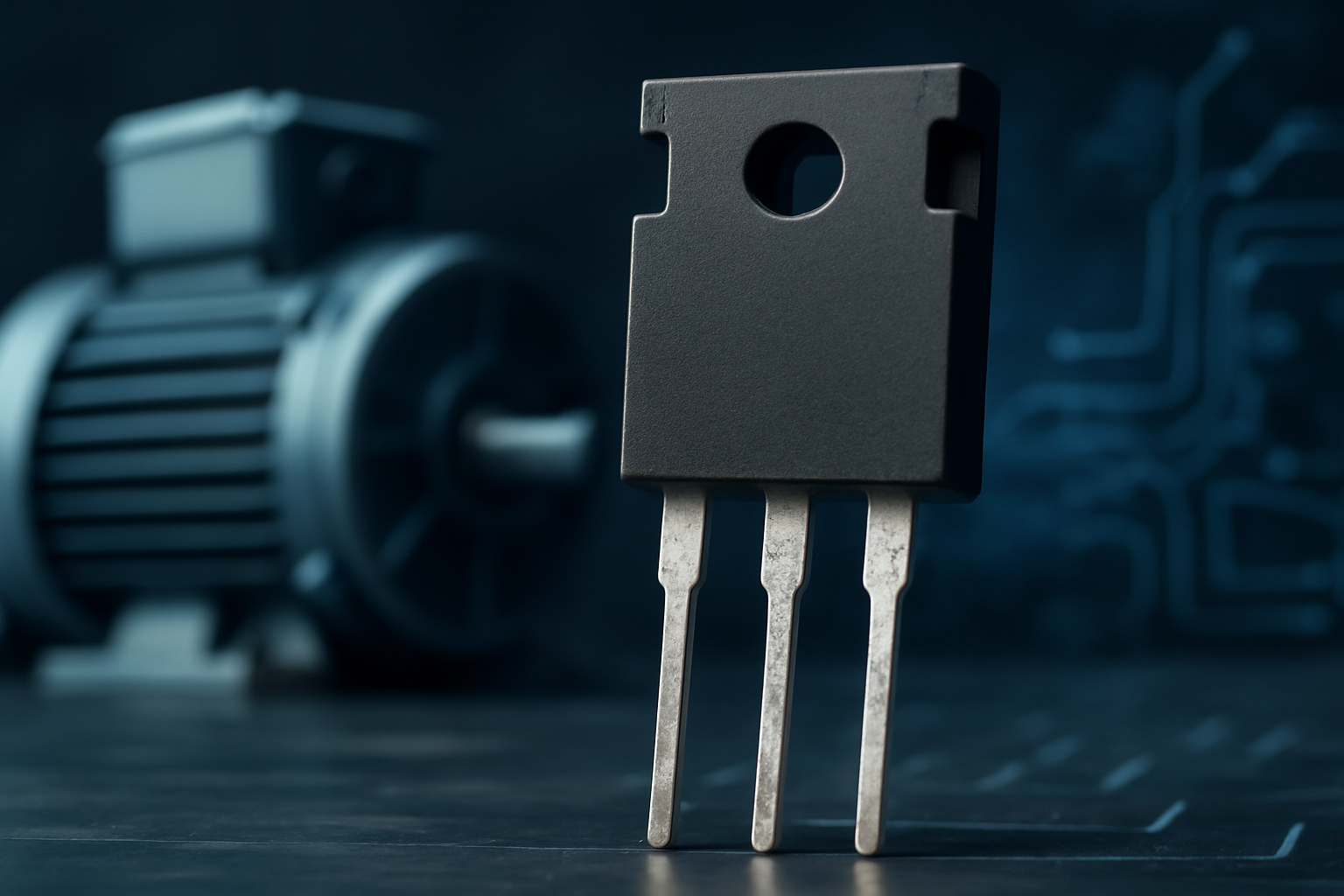

As MOSFET power density increases, thermal management becomes critical. Common strategies include copper base packages, die attach, and ceramic-insulated substrates.

High-reliability settings prefer packages like D2PAK, TO-247, and PDFN for thermal performance and compact design.

Proper selection of heatsinks, thermal pads, and forced-air systems directly influences MOSFET lifespan and system stability.

V. Future Evolution and Technology Convergence

Though GaN and SiC transistors are emerging, MOSFETs remain dominant due to their maturity, affordability, and flexible design footprint.

In the future, MOSFETs may be integrated with digital power control ICs into SoP modules, improving integration and intelligent control strategies.

In AI-controlled factories, MOSFETs may integrate with predictive algorithms for failure forecasting and lifespan estimation based on switching behavior data.

MOSFET / Industrial Drive / Component Efficiency