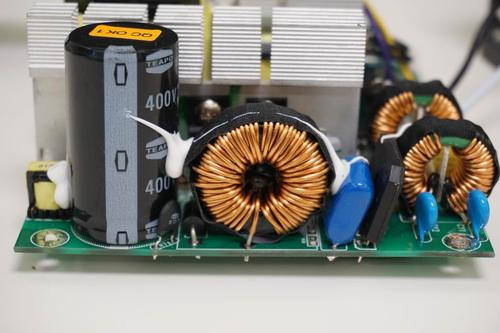

Core Functionality: Voltage Stabilization and Ripple Filtering

How electrolytic capacitors suppress ripple voltage in rectified DC outputs

When AC gets converted to DC through rectification, what comes out isn't always stable. There's usually this thing called ripple voltage hanging around - those annoying ups and downs in the signal that mess with system stability. That's where electrolytic capacitors come into play. These little workhorses basically store up energy when the voltage hits its peak moments and then let it go when things dip down, which helps flatten out the whole waveform. According to research from Power Electronics Journal back in 2023, good quality filtering can cut down on these ripples by more than half in most standard setups. What makes them so useful is their ability to handle large amounts of capacitance without needing complicated additional circuits. This means they stop those sudden voltage spikes before they have a chance to wreak havoc on delicate electronic parts throughout the system.

The role of high capacitance density in cost-effective smoothing

The reason electrolytic capacitors stand out is because they pack so much capacitance into such small spaces thanks to those thin oxide layers on their surfaces. When it comes to filtering out ripples in electrical signals, these capacitors offer real value for money compared to other options like ceramics. They actually do the same job but cost less overall. For manufacturers producing electronics in quantity, switching to electrolytics instead of buying several expensive parts can cut down on materials spending by around 40 percent according to industry reports from last year. What makes them particularly useful is how well they handle big surges of current while taking up minimal room inside gadgets we use every day from smartphones to household appliances.

Energy Storage and Dynamic Load Handling

Delivering burst current during load transients with low-ESR electrolytic capacitors

Electrolytic capacitors act as important energy storage units when there's a sudden need for more power. These components have really high capacitance density which allows them to discharge quickly and make up for drops in voltage levels. When electrical loads suddenly increase, say during motor start ups or when processors work hard on complex tasks, these parts can release their stored energy in just a few thousandths of a second to keep the bus voltage stable. Capacitors with low Equivalent Series Resistance (ESR) perform even better because they waste less power internally and generate less heat, plus they can handle currents up to twenty times what they normally do at rest. This fast response time stops systems from shutting down unexpectedly in industrial settings when operations change abruptly. Compared to batteries, electrolytic capacitors get back their charge very quickly after releasing it, so they're great for handling repeated power spikes. They fill those tiny gaps in power supply measured in microseconds, keeping things running smoothly in applications where maintaining stable voltage isn't optional but absolutely necessary.

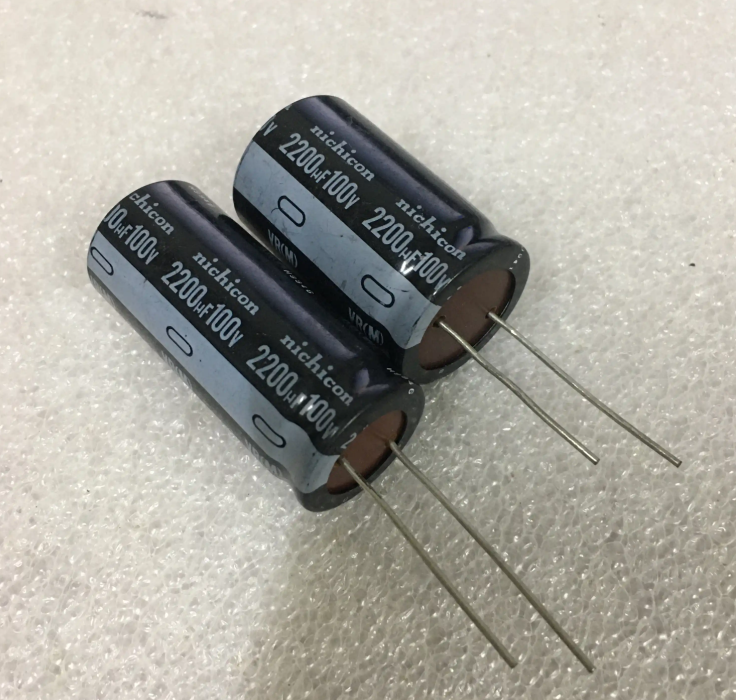

Design Advantages: Size, Cost, and Performance Trade-offs

Why electrolytic capacitors remain dominant despite aging and polarity constraints

Electrolytic capacitors still rule the market because they pack so much capacitance into small packages, which is exactly what designers need when working on tight spaces in power supplies. Sure, there are issues with these components getting old over time, mainly because the electrolyte inside tends to evaporate and they care about polarity direction, but the price per microfarad just can't be beat. Take a look at numbers: getting 1000 microfarads worth of capacitance from aluminum electrolytic parts will set someone back roughly 80 percent less money compared to going the ceramic route. That makes all the difference for projects where budgets matter most. Most engineers handle those aging problems by simply running the caps below their rated specs and keeping an eye on temperatures. As for worrying about polarity, manufacturers mark PCBs clearly and often run automatic checks using optical systems during production to catch any mistakes early on.

Comparing electrolytic capacitor performance against ceramic and film alternatives

Engineers looking at capacitors for their power supply designs need to consider several important factors when choosing between different types. Electrolytic capacitors work great for situations where lots of capacitance is needed at lower frequencies, but they tend to have much higher Equivalent Series Resistance (ESR) than ceramic options do. This matters because high ESR can cause problems with heat generation and overall performance stability. Film capacitors are another option that stands out for their long life span and stable characteristics over time, though they come at a price premium especially when large capacitance values are required. For many projects, the right capacitor isn't always the most obvious choice either. Sometimes what works best comes down to balancing budget constraints against performance needs in real world conditions.

| Parameter | Electrolytic | Ceramic | Film |

|---|---|---|---|

| Capacitance density | (High) | (Medium) | (Low) |

| ESR at 100kHz | (Higher) | (Lowest) | (Medium) |

| Frequency range | <100kHz | >1MHz | 10kHz-1MHz |

| Cost per μF | $0.0005 | $0.002 | $0.003 |

This performance-cost matrix explains why electrolytics remain preferred for bulk energy storage in DC power rails, where size and budget constraints outweigh high-frequency limitations. Modern hybrid designs often combine electrolytics with ceramic bypass capacitors to leverage both technologies' strengths.

Reliability Considerations and Modern Improvements

For years, electrolytic capacitors struggled with reliability problems mainly because their electrolytes would dry out over time and they couldn't handle heat well, particularly when exposed to high temperatures for extended periods. The good news is manufacturers are tackling these old issues with some pretty smart material science and better production methods. Capacitors today come with new electrolyte mixes that boil at much higher temperatures, so they don't evaporate as quickly. There's also this cool hybrid approach where they combine regular liquid electrolytes with conductive polymer layers inside the capacitor. This combination makes them last three times longer than older versions in most cases. Another benefit? These newer models have about 40% lower ESR which means they can handle more ripple current without losing their effectiveness. What really stands out though is how predictive maintenance works now. Capacitors actually have tiny sensors built in that keep an eye on things like internal temperature changes and shifts in capacitance levels. When something starts looking off, technicians get alerts so they can replace parts before anything breaks down completely.

FAQ Section

What is ripple voltage and why is it important to control it?

Ripple voltage refers to the residual periodic variation in direct current (DC) output, often occurring after rectification from alternating current (AC). Controlling it is crucial because it can cause instability and affect the performance of electronic components.

How do electrolytic capacitors help in energy storage?

Electrolytic capacitors store energy efficiently due to their high capacitance density. They can quickly discharge stored energy during sudden increases in electrical load, thereby maintaining voltage stability.

What are the limitations of using electrolytic capacitors?

Electrolytic capacitors can suffer from aging as their electrolytes evaporate over time. They also have polarity constraints, meaning they need proper orientation in circuits.

How do modern improvements aid electrolytic capacitor reliability?

Manufacturers have improved reliability by using new electrolyte mixes and incorporating conductive polymer layers, extending lifespan and reducing Equivalent Series Resistance (ESR).