الحاجة الماسّة إلى حماية الدوائر الكهربائية في التكنولوجيا الحديثة

في عصر تُشكّل فيه الهواتف الذكية وأجهزة الاستشعار الصناعية والشبكات الذكية عصب الحياة اليومية، يُمكن لارتفاع مفاجئ في الجهد الكهربائي لا يتجاوز ميكروثانية أن يُعطّل أنظمةً بأكملها. تُولّد صواعق البرق، وشبكات الطاقة المُعطّلة، والتفريغ الكهروستاتيكي الناتج عن التلامس البشري، طفراتٍ كهربائية تتجاوز تحمّلات جهد المعدات بآلاف الفولتات. تُكلّف هذه الأحداث الصناعات العالمية أكثر من 15 مليار دولار سنويًا في عمليات الإصلاح وفترات التوقف، وفقًا لتقارير السلامة الكهربائية الحديثة. في ظلّ هذا الوضع، أصبحت أنابيب التفريغ الغازي (GDTs) بمثابة أبطالٍ مجهولين، إذ تُوفّر آليات دفاعٍ قوية لا تُضاهيها الصمامات أو قواطع الدوائر الكهربائية التقليدية - بطيئة الاستجابة جدًا. تصميمها الفريد يجعلها لا غنى عنها للحفاظ على سلامة الأجهزة الإلكترونية الحساسة.

كيف تقوم أنابيب التفريغ الغازي بتعطيل التهديدات الكهربائية

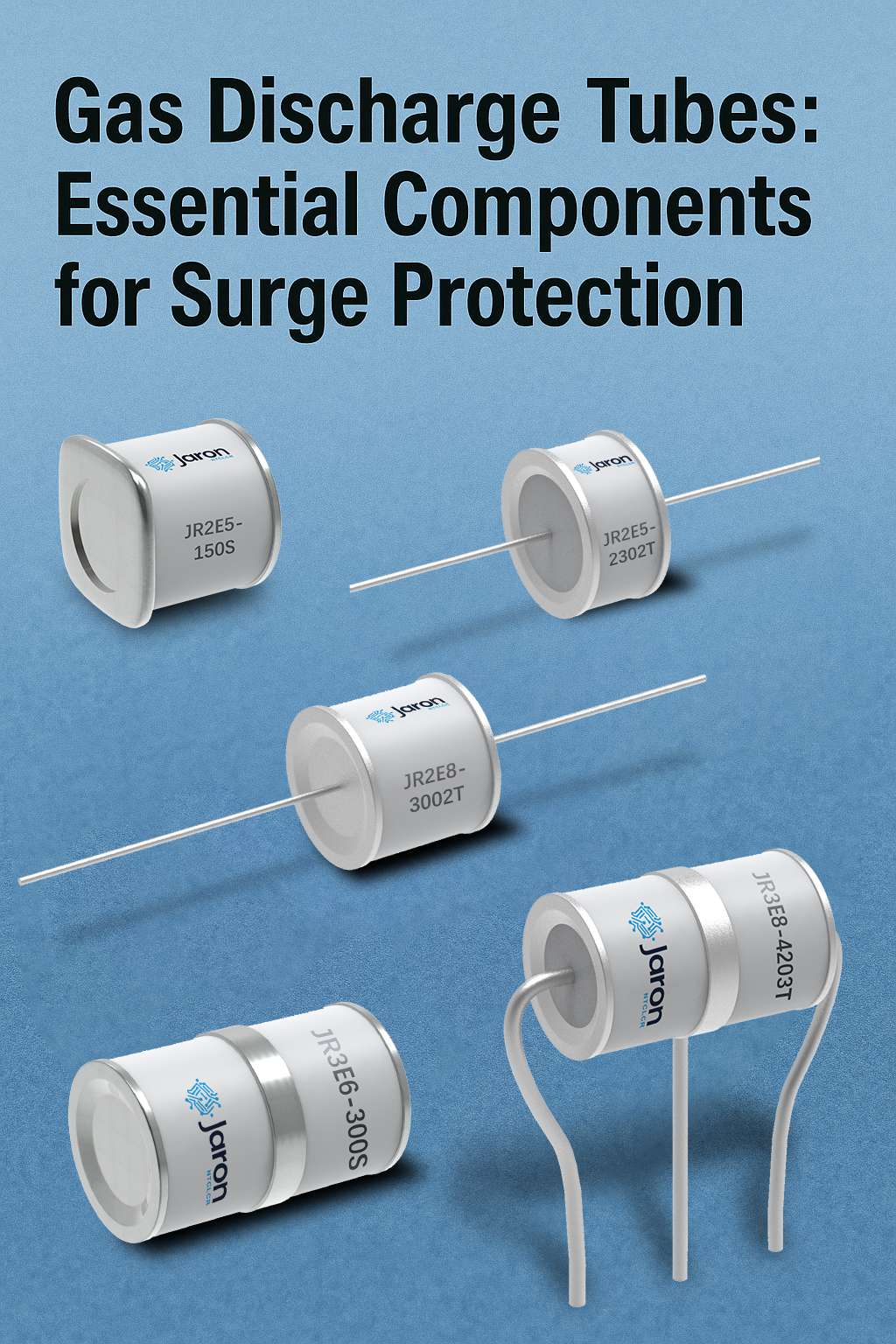

في قلب تصميم GDT وظيفة تكمن في بساطتها الظاهرة: أنبوب مغلق من السيراميك أو الزجاج يحتوي على غازات خاملة مثل الأرجون أو النيون، أو مزيج منهما، مع وجود إلكترودين أو ثلاثة داخله. وفي ظل الظروف التشغيلية العادية، يظل الغاز غير موصل، حيث يعمل كدارة مفتوحة تسمح بمرور التيار الآمن إلى الأجهزة المحمية. وعند حدوث زيادة جهد—سواء كانت ناتجة عن تغير عابر ناتج عن البرق أو اضطراب في شبكة الطاقة—يرتفع الجهد الكهربائي بين الإلكترودات بشكل حاد، مما يؤيّن جزيئات الغاز. ويؤدي هذا التأيين إلى تشكيل قناة بلازما موصلة، تقوم بإعادة توجيه التيار الزائد إلى الأرض بأقل مقاومة ممكنة.

ومن الجدير بالذكر، أن مزيلات الغاز (GDTs) تُعاد تهيئتها تلقائيًا بمجرد زوال الاندفاع الكهربائي. يبرد البلازما، ويستعيد الغاز حالته غير الموصلة، وتستأنف الأنبوبية دورها الوقائي. تميز هذه الخاصية ذاتية الاستعادة بينها وبين المقاومات التقليدية ذات الاستخدام الواحد، مما يجعلها خيارًا مثاليًا للبيئات التي تتعرض لاندفاعات كهربائية متكررة. كما تدعم قدرتها على تحمل تيارات اندفاعية تصل إلى 100 كيلو أمبير (kA) وتصنيفات جهد تتراوح بين 75 فولت إلى 3000 فولت موقعها كأجهزة حماية متعددة الاستخدامات.

تطبيقات متنوعة عبر الصناعات

تظهر قابلية مزيلات الغاز (GDTs) للتكيف عبر مختلف القطاعات، ولكل منها احتياجات حماية مختلفة. في قطاع الاتصالات، فإنها تحمي المحولات الضوئية وأجهزة الإرسال والاستقبال في محطات الجيل الخامس (5G)، حيث يمكن لأي اندفاع كهربائي بسيط أن يعطل نقل البيانات لملايين المستخدمين. تعتمد الخطوط الهاتفية، التي تتعرض غالبًا لعوامل الطقس الخارجي، على مزيلات الغاز (GDTs) لإبعاد الاندفاعات الناتجة عن الصواعق قبل أن تصل إلى أجهزة المودم أو أنظمة الهاتف الخاصة (PBX).

في أنظمة الطاقة المتجددة، مثل مزارع الطاقة الشمسية ومحطات الرياح، تحمي GDTs المحولات (inverters) ووحدات تخزين البطاريات. تتعرض هذه المنشآت، التي تقع في مناطق مفتوحة، لمخاطر صواعق متزايدة؛ حيث يمكن أن تذيب الصاعقة الواحدة بدون حماية GDTs الأسلاك وتوقف إنتاج الطاقة لأسابيع. وبالمثل، في الإلكترونيات السيارات، تحافظ GDTs على الحواسيب المركبة والمنافذ الشحن من ارتفاعات الجهد المفاجئة أثناء الشحن السريع، وهي قضية تكتسب أهمية متزايدة مع شيوع استخدام المركبات الكهربائية (EVs).

تستفيد الإلكترونيات الاستهلاكية بشكل كبير أيضًا. تدمج أجهزة التلفزيون الذكية وأجهزة ألعاب الفيديو والراوترات المنزلية مقاومات GDT صغيرة لمساعدتها على التكيف مع التقلبات المفاجئة في الجهد الكهربائي الناتجة عن منافذ الحائط. وعلى عكس أجهزة حماية زيادة الجهد الأكبر حجمًا، فإن مقاومات GDT تناسب التصاميم المصغرة للأجهزة، مما يضمن مظهرًا أنيقًا دون التأثير على السلامة.

الابتكارات التي تقود تطور مقاومة الغاز (GDT)

مع تقدم التكنولوجيا، يواصل مصنعو أجهزة التفريغ الغازي (GDT) توسيع الحدود لتلبية متطلبات أكثر صرامة. وقد ساهمت تركيبات جديدة من خلطات الغاز في تقليل زمن الاستجابة إلى أقل من 10 نانوثوانٍ، وهو تحسن بالغ الأهمية بالنسبة لخطوط البيانات عالية السرعة حيث يمكن أن تتلف التأخيرات الإشارات. كما تمكنت مواد الإلكترود المحسّنة، مثل النحاس المطلي بطبقة من النيكل، من زيادة عمر أجهزة GDT لتصل إلى أكثر من 100 دورة انحناء كهربائي، مقارنةً بـ20 دورة في الإصدارات القديمة، وهو ما يمثل أهمية كبيرة للبيئات الصناعية التي تتعرض لاضطرابات كهربائية متكررة.

الاتجاه الرئيسي الآخر هو أنظمة الحماية الهجينة، حيث يعمل المكثف الغازي (GDT) جنبًا إلى جنب مع مقاومات أكسيد المعادن المتغيرة (MOVs) ومثبطات الجهد العابر (TVS). يقوم المكثف الغازي (GDT) بمعالجة الاندفاعات ذات الطاقة العالية، بينما تعالج مقاومات أكسيد المعادن المتغيرة (MOVs) والأجهزة مثبطة الجهد العابر (TVS) الاضطرابات العابرة ذات الجهد المنخفض والتردد العالي، مما يخلق دفاعًا متعدد الطبقات. هذه العلاقة التكاملية بالغة الفعالية في الشبكات الذكية، حيث يمكن لاندفاع واحد أن يؤثر على ملايين العدادات وأجهزة الاستشعار المتصلة.

مستقبل المكثفات الغازية (GDTs) في عالم hyperconnected

إن ارتفاع استخدام إنترنت الأشياء (IoT) والمدن الذكية يزيد من الحاجة إلى حماية ذكية ضد زيادة التيار. يتم دمج أنابيب التفريغ الغازية من الجيل التالي (GDTs) مع وحدات تحكم صغيرة لتمكين المراقبة في الوقت الفعلي: حيث تنقل أجهزة الاستشعار المدمجة في الأنابيب بيانات حول تكرار شدة الاندفاعات، مما يسمح بالصيانة التنبؤية والتعديلات على النظام. على سبيل المثال، في المباني الذكية، يمكن استخدام هذه البيانات لإطلاق إيقاف تلقائي للأنظمة غير الأساسية أثناء العواصف الشديدة، مع التركيز على حماية البنية التحتية الحيوية مثل المصاعد وأنظمة الأمان.

تتنبأ توقعات الصناعة بزيادة سنوية قدرها 7.2٪ في الطلب على أنابيب التفريغ الغازية (GDTs) حتى عام 2030، مدفوعةً بتوسيع الطاقة المتجددة وانتشار شبكات الجيل الخامس (5G). ومع تصميم الأجهزة لتكون أكثر ترابطًا، فإن تكلفة أضرار زيادة التيار ستستمر في الارتفاع، مما يجعل من أنابيب التفريغ الغازية ليست مجرد مكونات، بل عناصر أساسية في السلامة الكهربائية.

باختصار، إن أنابيب التفريغ الغازي ليست مجرد إكسسوارات فحسب، بل هي حراس أساسيون للتكنولوجيا الحديثة. إن قدرتها على التكيف مع التهديدات المت evolving، والتكامل مع الأنظمة الذكية، والحماية عبر الصناعات تضمن بقائها في صميم استراتيجيات حماية الدوائر الكهربائية لعقود قادمة. وفهم دورها هو المفتاح لبناء نظم كهربائية متينة في عالم يصبح أكثر اتصالاً يوماً بعد يوم.