Как работают диоды TVS: от нормального режима к защите от перенапряжений

Механизм отклика на переходные процессы напряжения и события электростатического разряда

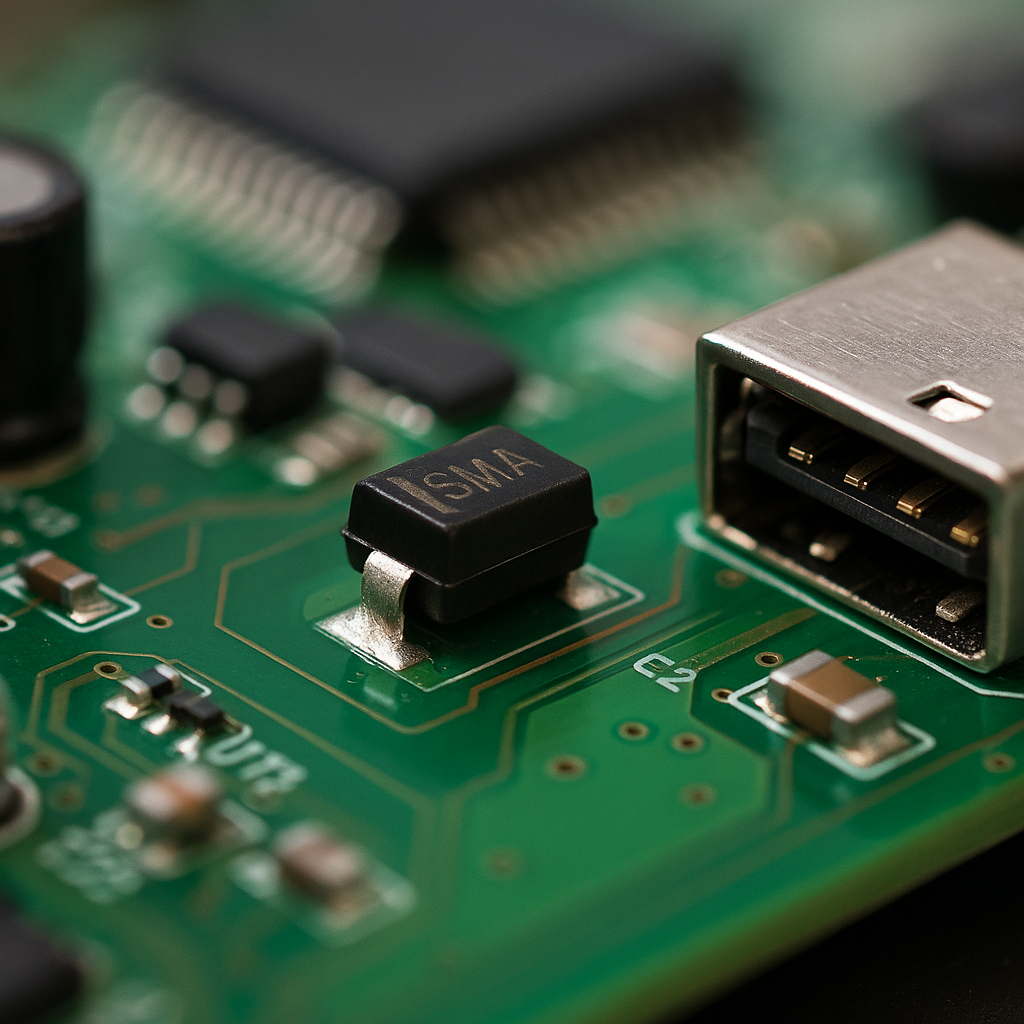

Диоды TVS действуют как быстро реагирующие переключатели напряжения, которые переходят из состояния высокого сопротивления в состояние низкого сопротивления за миллиардные доли секунды при возникновении внезапных скачков напряжения. Когда статическое электричество накапливается и разряжается через цепи, эти компоненты вступают в действие, чтобы защитить чувствительную электронику, ограничивая напряжение до безопасных уровней. Недавний отраслевой отчет за 2023 год показал, что современные диоды TVS уменьшают опасные скачки напряжения на 70% и почти до нуля по сравнению с незащищенными системами. У большинства моделей двусторонние значения емкости находятся в диапазоне от 0,5 до 50 пикофарад, что означает, что они не мешают обычной передаче сигналов, но остаются чувствительными к ситуациям, требующим быстрого реагирования и максимальной защиты.

Работа в нормальных и перенапряженных условиях

Диоды TVS обычно демонстрируют токи утечки менее 1 мкА в нормальном режиме работы, поэтому они практически не влияют на эффективность энергопотребления. Если напряжение превышает так называемое обратное напряжение выдержки (или VRWM), диоды переходят в режим лавинного пробоя, что означает, что они начинают проводить электричество в контролируемом режиме. Этот эффект ограничения предотвращает чрезмерный рост скачков напряжения, что крайне важно для защиты чувствительных компонентов, таких как микроконтроллеры. В качестве примера можно привести TVS-диоды автомобильного класса. Эти устройства способны выдерживать повторные разряды электростатического электричества до 30 киловольт, срабатывают за доли наносекунды и обеспечивают надежную работу даже в тяжелых условиях, где обычные компоненты могут выйти из строя.

Пример: Быстрая реакция в электронике для потребительского рынка при электростатическом разряде

Ограничители перенапряжения в портах USB-C смартфонов значительно сократили количество отказов, вызванных электростатическими разрядами — на самом деле, примерно на 83%, благодаря их невероятно быстрому времени отклика менее наносекунды. Недавно один из ведущих производителей смартфонов провел испытания, которые показали нечто впечатляющее. При воздействии сильных контактных разрядов напряжением 15 кВ, эти диоды снижали уровень напряжения на входе микросхемы всего до 6 вольт. Это намного ниже уровня, который обычно вызывает проблемы — обычно около 12 вольт. Что еще лучше для производителей, вся эта защита реализуется без снижения скорости передачи данных. Порты по-прежнему поддерживают полную пропускную способность 10 гигабит в секунду, поэтому пользователи не замечают никакой разницы при передаче файлов или зарядке устройств. Современные технологии ограничителей перенапряжения действительно позволяют обеспечить бесперебойную работу, не жертвуя ни производительностью, ни качеством сигнала.

Тренд: Улучшения в скорости срабатывания и надежности

Новые стабилитроны TVS изготовлены из карбида кремния (SiC), что позволяет им реагировать всего за 500 пикосекунд, при этом обеспечивая импульсную мощность до 600 Вт. Особенно впечатляет, что производители теперь могут гарантировать более 100 тысяч циклов перенапряжения при полном номинальном токе, что примерно в четыре раза превышает долговечность устройств, доступных в 2019 году. Эти улучшения имеют большое значение для тяжелых условий эксплуатации, таких как базовые станции 5G и системы зарядки электромобилей, где надежная защита от переходных процессов — это не просто преимущество, а необходимость для безопасной и бесперебойной работы систем в течение длительного времени.

Основные параметры для выбора стабилитронов TVS для оптимальной защиты

Напряжение пробоя, напряжение ограничения и ток утечки — объяснение

Правильный выбор стабилитрона TVS зависит от понимания трех ключевых параметров:

- Напряжение пробоя (V БР ): Напряжение, при котором диод начинает пропускать значительный ток, обычно устанавливается на 10–15% выше нормального рабочего напряжения.

- Напряжение зажима (V C ): Максимальное напряжение, передаваемое на защищаемую цепь во время переходного процесса; более низкие значения лучше защищают чувствительные компоненты (например, <50 В для USB-C).

- Ток утечки (I Г ): Малый ток, протекающий в нормальных условиях; значения ниже 5 мкА предотвращают потерю энергии и ложные срабатывания, особенно важны для датчиков с батарейным питанием и в автомобильной электронике.

Импульсный ток и способность рассеивать энергию

Пиковый импульсный ток (IPP) по сути показывает, какой максимальный краткосрочный ток может выдержать диод, не повреждаясь. Это особенно важно, когда речь идет, например, о блоках питания серверов, которые могут подвергаться воздействию мощных скачков напряжения от молний, при которых токовые импульсы легко могут превышать 200 ампер. Что касается количества энергии, которое эти устройства должны поглощать, оно измеряется в джоулях. Большинство промышленных приложений требуют устройств, способных выдержать минимум 150 джоулей, прежде чем они выйдут из строя. Если мы хотим, чтобы наши системы служили долго и при этом обеспечивали защиту от скачков напряжения, то разумно поддерживать коэффициент ограничения (VC, деленное на VBR) на уровне ниже 1,5. Это помогает снизить степень износа всех компонентов, подключенных после диода, что в долгосрочной перспективе позволяет экономить деньги, так как детали выходят из строя реже.

Пример из практики: выбор параметров в цепях преобразователей постоянного тока (DC/DC)

Понижающий преобразователь постоянного тока 24 В столкнулся с частыми сбоями из-за переходных процессов при коммутации реле. Инженеры решили эту проблему, выбрав диод TVS со следующими характеристиками:

- В БР > 30 В (на 20% выше максимального рабочего напряжения)

- Я PP ≥ 150 А (проверено по тестовым импульсам ISO 7637)

- Емкость p-n перехода <10 пФ для сохранения характеристик при высокочастотной коммутации

Этот целенаправленный выбор снизил количество сбоев в эксплуатации на 75% и обеспечил соответствие автомобильному стандарту надежности AEC-Q101.

Стратегия: Соответствие характеристик TVS требованиям конкретного применения

Используйте эту методологию для согласования характеристик TVS с требованиями применения:

| Требование применения | Ключевые параметры | Метод проверки |

|---|---|---|

| Высокоскоростные порты передачи данных | Ёмкость перехода | Тестирование диаграммы глаза |

| Переходные процессы в электросети | Поглощение энергии | моделирование формы сигнала 8/20 мкс |

| Системы аккумуляторов | Ток утечки | Анализ теплового выхода из строя |

| Проверка проектов с использованием стандартизованных импульсных форм сигналов — IEC 61000-4-5 для промышленной среды и ISO 10605 для автомобильной отрасли — обеспечивает безопасный уровень напряжения ограничения ниже порога повреждения компонентов |

Односторонние и двусторонние защитные диоды: различия и сценарии применения

Принципы работы, основанные на полярности и требованиях цепи

Существует два основных типа TVS-диодов: однонаправленные и двунаправленные. Однонаправленные диоды лучше всего подходят для использования в повседневных цепях постоянного тока, таких как стандартные 5-вольтовые порты USB на наших устройствах или 12-вольтовые системы в автомобилях, где скачки напряжения происходят только в одном направлении. Эти диоды, по сути, просто находятся в режиме ожидания, пока не произойдет скачок напряжения, после чего они активируются в режиме обратного смещения, при этом позволяя обычному току продолжать течь через них в обычном режиме. В свою очередь, двунаправленные TVS-диоды состоят из двух лавинных диодов, соединенных друг с другом встречно. Они очень удобны для защиты сложных цепей переменного тока и сигналов, которые могут двигаться в обоих направлениях, например, системы CAN-шины или линии связи RS-485. Что касается борьбы как с положительными, так и с отрицательными скачками напряжения, то двунаправленные модели справляются с этим намного эффективнее. Согласно исследованию, опубликованному в прошлом году в журнале Circuit Protection Journal, использование двунаправленной защиты вместо отдельных однонаправленных компонентов может сократить количество необходимых деталей примерно на 40% в установках трехфазного промышленного оборудования.

Применение в USB, HDMI и CAN-интерфейсах

- Однонаправленный : Предпочтительно для портов USB 3.2 и HDMI 2.1, где низкая ёмкость (до 0,5 пФ) обеспечивает защиту от электростатического разряда до 30 кВ без ухудшения качества сигнала.

- Двунаправленный : Необходим для автомобильных CAN-шин благодаря выдерживаемому напряжению до ±45 В и соответствию стандарту IEC 61000-4-5.

- : Критичен для сетей RS-485, где двунаправленные диоды сохраняют целостность сигнала при скорости передачи данных свыше 100 Мбит/с.

Пример: Двунаправленные TVS-диоды в автомобильных CAN-системах

Один крупный европейский автопроизводитель зафиксировал снижение гарантийных требований почти на две трети после внедрения двунаправленных подавителей переходных напряжений (TVS) в своих CAN-шинах. Эти подавители легко справляются с надоедливыми скачками напряжения, достигающими плюс/минус 60 вольт от сброса нагрузки генератора. В то же время, они обеспечивают ток утечки ниже 1 наноампера даже при стандартных дифференциальных уровнях напряжения в 2,5 вольта. Это означает, что автомобили могут надежно обмениваться данными в самых разных и тяжелых дорожных условиях.

Тренд: Растущее внедрение в высокоскоростных и промышленных системах связи

Мировой рынок двунаправленных TVS-диодов ожидается рост на 11,8% ежегодно до 2030 года, что обусловлено следующими факторами:

- 5G базовые станции, требующие защиту данных на скорости 20 Гб/с с ультранизкой ёмкостью (<0,3 пФ)

- Промышленные датчики IoT, требующие квалификации AEC-Q101 класса 1 (-40°C до +125°C)

- Инверторы для возобновляемой энергетики, требующие защиты от перенапряжения ±2 кВ согласно стандарту IEC 61643-31

Распространенные применения TVS-диодов в современных электронных системах

ЭСД-защита в бытовой электронике и мобильных устройствах

Диоды TVS служат основной линией обороны при защите смартфонов, ноутбуков и носимых устройств от повреждений, вызванных электростатическим разрядом. Эти компоненты обладают чрезвычайно низкими значениями емкости менее 0,5 пФ, что означает, что они не мешают сигналам на тех высокоскоростных интерфейсах, на которые мы полагаемся сегодня, таких как подключения USB Type-C или HDMI. Кроме того, они способны выдерживать события электростатических разрядов, достигающих плюс или минус 30 киловольт. Согласно исследованию, опубликованному ESDA в прошлом году, производители, перешедшие на диоды TVS, отметили значительное снижение проблем, связанных с электростатическим разрядом, — примерно на 62% меньше проблем, чем ранее при использовании других методов защиты. Наиболее современные поколения этих диодов теперь обеспечивают еще лучшие эксплуатационные характеристики, особенно для новых стандартов подключения, таких как Thunderbolt и DisplayPort. Они позволяют создавать компактные конструкции, сохраняя при этом высокий уровень защиты, что делает их подходящими для передачи данных на скоростях, приближающихся к 40 гигабитам в секунду, без какого-либо заметного ухудшения сигнала.

Защита чувствительных интегральных схем и микроконтроллеров от скачков напряжения

Диоды TVS служат для защиты различных компонентов, включая аналоговые датчики, ИС управления питанием и микропроцессоры. Они работают, отводя внезапные скачки напряжения, возникающие из-за таких источников, как реле, работающие двигатели и импульсные источники питания. При выборе этих диодов большинство инженеров предпочитают использовать диоды с током утечки менее 1 мкА, а напряжение ограничения должно быть примерно на 20% ниже максимального напряжения, которое может выдержать ИС. В частности, для медицинских приложений IoT массивы TVS становятся абсолютно необходимыми. Эти массивы защищают от быстрого возрастания напряжения (до 100 вольт в микросекунду), которое может повредить чувствительные аналогово-цифровые схемы. Такая защита критически важна, поскольку эти переходные процессы часто возникают вследствие радиочастотных помех или при включении и выключении индуктивных нагрузок. Без надлежащей защиты измерения могут быть искажены, а целые системы могут неожиданно выйти из строя.

Кейс: Защита от перенапряжения в автомобильной и промышленной электронике

Проведенные в 2022 году испытания в автомобильных системах CAN-шины показали, что применение двунаправленных TVS-диодов сокращает ошибки связи, вызванные скачками напряжения, примерно на 83% при условиях тестирования ISO 7637-2. В ходе испытаний эти диоды выдерживали сложные токовые импульсы 10/1000 мкс, достигающие 200 ампер в стандартных 24-вольтовых системах, при этом внутренняя температура оставалась ниже критической отметки в 125 градусов Цельсия. Для промышленных применений разъемы, построенные с интегрированными TVS-диодами, обеспечивают защиту от гигантских скачков напряжения до 6 киловольт от ударов молнии, которые могут повредить чувствительные модули ввода/вывода ПЛК. Эти разъемы изначально соответствуют строгим требованиям стандарта IEC 61000-4-5, поэтому нет необходимости в дополнительных фильтрах или компонентах для обеспечения соответствия.

Стратегии проектирования для эффективной интеграции TVS-диодов

Оптимальное размещение и компоновка для максимального отвода импульсного тока

Для эффективной защиты размещайте TVS-диоды как можно ближе к точкам входа переходных процессов — таким как разъемы, входы питания или порты ввода/вывода — чтобы минимизировать паразитную индуктивность. Например, размещение на расстоянии 1 см от порта USB снижает риск распространения импульса на 60% по сравнению с размещением дальше по цепи. Рекомендуется:

- Использовать короткие широкие печатные проводники для снижения импеданса

- Избегать переходных отверстий между диодом и защищаемым компонентом

- Обеспечить путь возврата с низким импедансом к земле

Устанавливать пороговые напряжения ограничения на 10–20% выше максимального рабочего напряжения системы, чтобы избежать ложных срабатываний и обеспечить быстрый отклик (например, используйте TVS-диоды с напряжением 5,5–6 В для систем с напряжением 5 В).

Сбалансированная защита по уровню ограничения и нагрузке на компоненты

Выбирайте TVS-диоды в зависимости от уровня нагрузки, специфичной для конкретного применения:

| Параметры | Чувствительная электроника | Промышленные системы |

|---|---|---|

| Предельное напряжение | 5–15 В | 15–30 В |

| Пиковый импульсный ток | 50 А | 100–300 А |

| Пропускная способность | <0,5 пФ | <5 пФ |

В приложениях автомобильной шины CAN, двунаправленные TVS-диоды с напряжением пробоя 24 В и током перегрузки 200 А обеспечивают надежность 99,8% в подавлении переходных процессов при сбросе нагрузки, сохраняя ток утечки менее 3 мА в нормальном режиме работы.

Стратегия: Обеспечение целостности сигналов в высокоскоростных линиях передачи данных

Для высокоскоростных интерфейсов, таких как USB 3.2 (10 Гб/с), HDMI 2.1 (48 Гб/с) и PCIe 5.0, используйте TVS-диоды с емкостью менее 0,3 пФ для предотвращения искажения сигналов. Применяйте методы трассировки с согласованием импеданса:

- Соблюдайте равномерность длины проводников с отклонением ±5%

- Предусмотрите сплошные слои земли под компонентами TVS

- Соблюдайте допуск ±5% на характеристическое сопротивление (например, 85 Ом для USB4)

Оптимизированная интеграция TVS-диодов позволяет снизить отражение сигналов на 40% в сетях Ethernet со скоростью 25 Гб/с, обеспечивая при этом полноценную защиту от электростатического разряда (8 кВ) по стандарту IEC 61000-4-2, что доказывает возможность совместного применения высокой степени защиты и высокоскоростных характеристик.

Часто задаваемые вопросы (FAQ)

Для чего используются TVS-диоды?

TVS-диоды используются для защиты электронных компонентов от скачков напряжения, накопления статического электричества и электрических перенапряжений, обеспечивая безопасную работу систем без неожиданных сбоев.

Почему TVS-диоды обладают быстрым временем отклика?

Быстрое время отклика позволяет TVS-диодам быстро переходить из состояния высокого сопротивления в состояние низкого сопротивления, ограничивая скачки напряжения и обеспечивая эффективную защиту.

В чем разница между однонаправленными и двунаправленными диодами TVS?

Односторонние TVS-диоды защищают от скачков напряжения только в одном направлении, как правило, в цепях постоянного тока. Двусторонние TVS-диоды справляются со скачками напряжения в обоих направлениях, что особенно полезно в цепях переменного тока.

Как TVS-диоды способствуют сохранению целостности сигналов?

Диоды TVS с низкой емкостью могут защищать интерфейсы, такие как USB и HDMI, без ухудшения качества сигнала, обеспечивая высокоскоростную передачу данных.

Содержание

- Как работают диоды TVS: от нормального режима к защите от перенапряжений

- Основные параметры для выбора стабилитронов TVS для оптимальной защиты

- Односторонние и двусторонние защитные диоды: различия и сценарии применения

- Распространенные применения TVS-диодов в современных электронных системах

- Стратегии проектирования для эффективной интеграции TVS-диодов

- Часто задаваемые вопросы (FAQ)