Based on real part numbers, this article analyzes the application scenarios of MCUs in industrial control and smart terminals, covering selection logic, case studies, and global procurement trends.

I. Why MCUs Remain the Control Core of Electronic Systems

In an era dominated by AI processors and high-performance SoCs, MCUs still serve as the control backbone of most industrial equipment and smart devices.

The reasons are practical: stability, low power consumption, long lifecycle support, and predictable cost.

From PLCs and industrial gateways to smart meters, POS terminals, and chargers, MCUs remain indispensable.

II. MCU Parameters That Engineers Actually Care About

|

Parameters |

Engineering Significance |

|

Core |

Determines program size and operational stability |

|

Flash / SRAM |

3.3V / 5V compatibility |

|

Operating Voltage |

Industrial grade -40~85°C / -40~105°C |

|

Temperature Range |

UART / SPI / I2C / CAN / USB |

|

Peripherals |

LQFP / QFN / BGA |

|

Package |

Determines program size and operational stability |

MCU selection is not about clock speed alone. Engineers focus on:

Memory headroom

Peripheral completeness

Industrial temperature ratings

Package compatibility with existing PCB designs

III. MCUs in Industrial Control: Real Models in Production

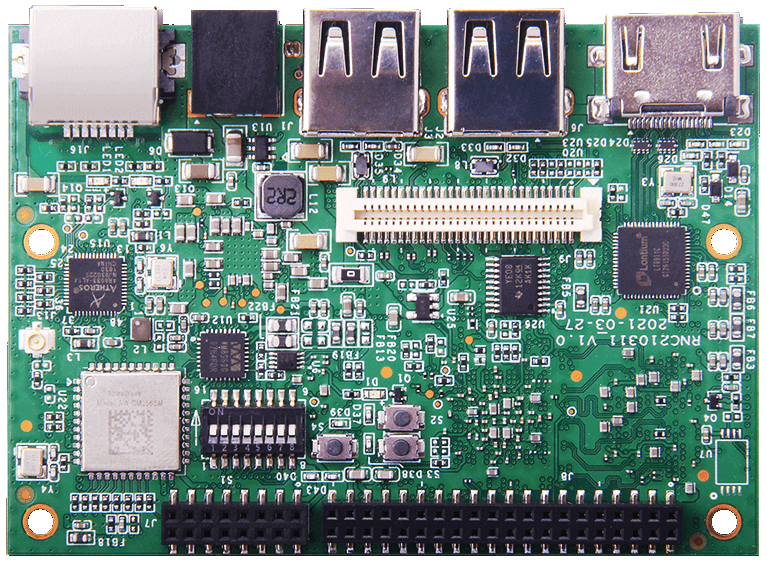

In industrial automation, HMI, and PLC I/O modules, the following MCU models are widely used in real-world projects:

Common Industrial-Grade MCU Part Numbers

STM32F103C8T6(STMicroelectronics)

Cortex-M3,72MHz

Widely used in PLCs, industrial instruments, and control boards

Long-term supply, mature ecosystem

STM32F407VGT6

Cortex-M4 with FPU

For industrial HMIs and human-machine interfaces

Excellent CAN/USB/Ethernet support

NXP LPC1768FBD100

Cortex-M3

Still widely used in European industrial control projects

These MCUs are widely deployed in Germany, Poland, and Italy, where industrial customers prioritize lifecycle stability and certification continuity.

IV. MCUs in Consumer and Smart Devices

In consumer electronics and smart devices, the focus of MCUs is shifting towards:

Low power consumption (Sleep/Stop mode)

Cost control

Miniaturization of packages

Model examples

STM32G030F6P6

Cortex-M0+

Widely used in smart home appliances and control panels

Microchip ATmega328P-AU

Core MCU of the Arduino ecosystem

Extensively used in smart control modules and educational equipment

NXP KL25Z128VLK4

Cortex-M0+

Commonly found in consumer-grade control boards and sensor nodes

These MCUs are heavily sourced in India, Vietnam, and Mexico, where ODM manufacturing emphasizes low MOQ, spot stock, and fast turnaround.

V. Case Study: MCU Selection for an Industrial HMI Board

An industrial HMI project initially used a low-end MCU and encountered the following problems:

UI refresh latency

High probability of communication interruptions

Insufficient expansion interfaces

After evaluation, the design migrated to:

STM32F407VGT6

External SDRAM + TFT controller

Improved CAN and RS485 stability

Final Results:

UI responsiveness improved by approximately 40%

System stability significantly improved

The project successfully entered mass production in the Eastern European market.