Jak diody řídí tok proudu v elektronických obvodech

Princip funkce diody jako jednosměrného ventilu pro elektrický proud

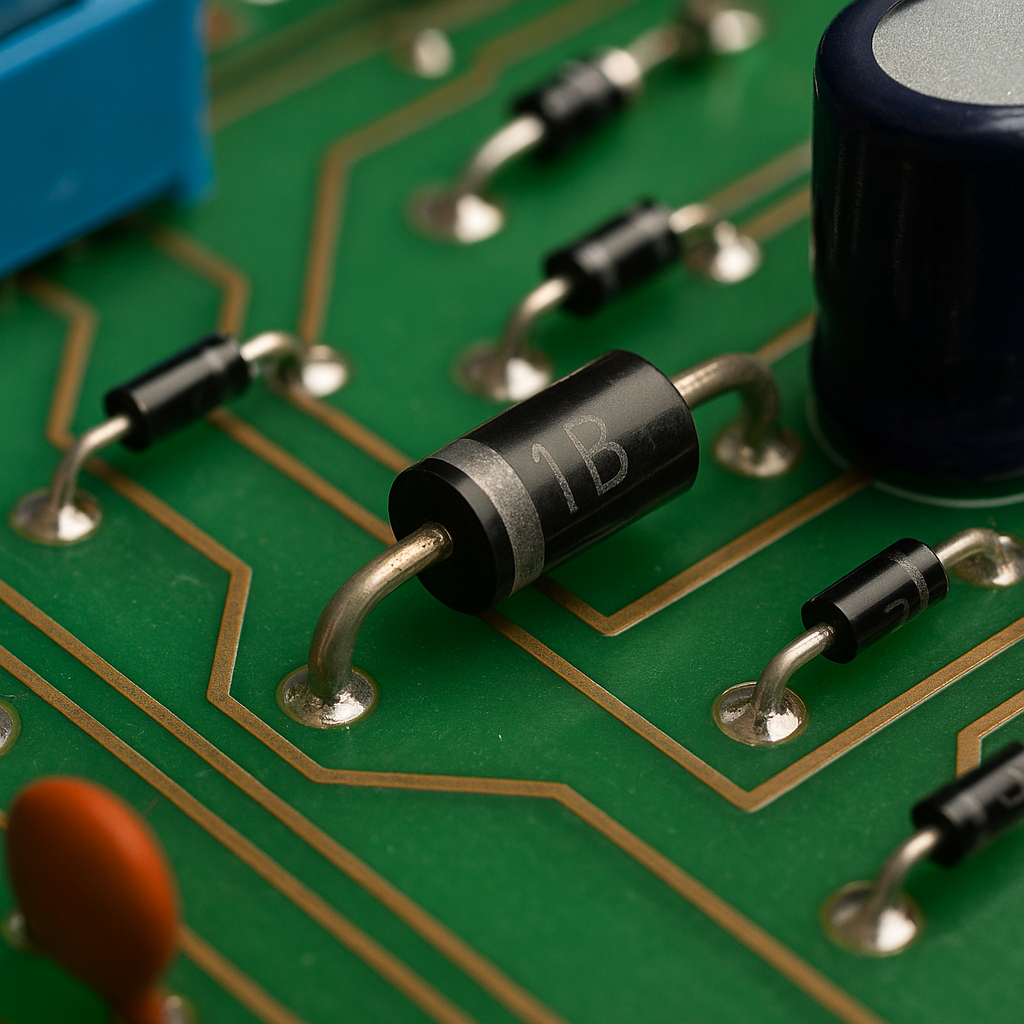

V obvodech fungují diody podobně jako jednosměrné dveře díky jejich PN přechodové konfiguraci. Když správně přivedeme napětí (přímé polarizování), mohou elektrony rychle projít z kladné strany (anody) na záporný konec (katodu). Pokud se však situace obrátí, tyto malé součástky prakticky úplně zablokují průchod proudu, podobně jako dobře navržený zpětný ventil zastaví tok v opačném směru. Podle nedávného výzkumu zveřejněného v loňském roce v časopise Semiconductor Physics Review dokážou typické křemíkové PN přechody něco docela působivého – umožní průchod tisíckrát většího proudu ve správném směru ve srovnání s tím, co se pokouší protékat zpět. Proto inženýři tak velmi spoléhají na diody pro úkony, jako je přeměna střídavého proudu na stejnosměrný v napájecích zdrojích a ochrana zařízení před potenciálně škodlivými zpětnými proudy.

Vysvětlení funkce diod v přímém a zpětném polarizačním režimu

Při připojení kladného napětí k anodě (přímé předpnutí) se depleční oblast na přechodu zmenšuje, což umožňuje proud procházet efektivně s úbytkem napětí okolo 0,7 V u křemíkových diod. Při zapojení diody v nepřímém předpnutí (reverzní polarita) se děje přesný opak – izolační bariéra se zvětšuje, čímž se proud sníží na úroveň pouhých nanoampér. To je velmi důležité, protože to chrání ostatní části obvodu před poškozením. Skutečnost, že se diody v závislosti na polaritě chovají zcela odlišně, je přesně tím, co je činí tak užitečnými. Proto inženýři využívají diody v obvodech jako jsou usměrňovače nebo obvody pro omezení napětí v různorodých elektronických aplikacích.

Vliv přechodové bariéry na řízení proudu

Vestavěný přechodový potenciál (0,3 V u germania vs. 0,7 V u křemíku) určuje prahové napětí diody. Materiály s vyšší bariérou umožňují lepší odolnost proti zpětnému napětí, nižší únikové proudy a zvýšenou teplotní stabilitu, což činí křemík preferovanou volbou pro většinu výkonových a digitálních aplikací.

Materiálové vědy týkající se křemíkových a germaniových diod

| Vlastnost | Křemíkové diody | Germaniové diody |

|---|---|---|

| Propustné napětí | 0.7V | 0,3V |

| Maximální Teplota | 175°C | 85 °C |

| Zpětný únik | <1 µA | 100 µA |

Křemík dominuje moderní obvody díky své tepelné odolnosti a kompatibilitě výroby, zatímco germanium zůstává specializovaný pro nízkonapěťové RF aplikace, kde je kritická minimální velikost propustného napěťového úbytku.

Dioda pro ochranu proti přepětí a obrácené polaritě

Použití diod v ochraně obvodu: Ochrana proti přepětí a potlačení přepěťových špiček

V dnešních elektronických zařízeních diody plní klíčovou ochrannou funkci proti nebezpečným špičkám napětí. Pokud jde o diody pro potlačení přechodných napětí (TVS), aktivují se téměř okamžitě – mluvíme tu o nanosekundách – a potlačí tyto obtížné napěťové skoky způsobené například elektrostatickým výbojem nebo událostmi ESD. Diody poté přesměrují tento škodlivý proud pryč od citlivé elektroniky, než dojde k poškození. Průmyslové stroje čelí rovněž zvláštním výzvám. Fakultní provozy, které se potýkají s bleskovými výboji nebo zařízeními napájenými velkými motory, často instalují tyto obvody s diodami jako ochranné opatření. Udržují napětí v mezích, které systém bezpečně vydrží. Co činí tato TVS řešení tak účinnými, je způsob, jakým zvládají jak energetické požadavky různých aplikací, tak zároveň dostatečně rychlou reakci potřebnou k zachycení náhlých skoků energie, které by jinak mohly spálit drahé komponenty.

Ochrana proti obrácené polaritě pomocí sériových a paralelních diod

Pokud je napájení omylem připojeno v opačném směru, mohou obvody závažně selhat. Diody zapojené do série fungují jako zpětné ventily pro elektrický proud procházející napájecími zdroji. Typ Schottky těchto diod má nižší prahové napětí, a proto při průchodu proudu neztrácí tolik energie. Další možností jsou shuntové diody, které bezpečně odvádějí jakýkoli zpětný proud do země. Ty fungují nejlépe v systémech, kde prochází proudem přes dvacet ampér. V praxi se rozhodování o návrhu obvodů soustředí na vyvážení jednoduchosti obvodu proti množství generovaného tepla a ztracené energie, které každé řešení způsobuje. Zkušenosti ukazují, že to, co vypadá skvěle na papíře, se v reálných provozních podmínkách někdy rozpadá.

Studie případu: Implementace diod v automobilových napájecích systémech

Způsob, jakým automobily zvládají své 12V a 48V elektrické systémy, opravdu závisí na tom, jak dobře integrují ochranné diody po celém vozidle. Jedna velká společnost vyrábějící elektrická vozidla zaznamenala pokles záručních problémů o přibližně 37 %, když začala umisťovat tyto speciální TVS diody přímo na připojení baterie. Tyto komponenty pomáhají pohltit náhlé špičky napětí, které mohou dosáhnout až 60 voltů při vypnutí zátěže. Navíc byly na vstupy infotainmentsystému nainstalovány řady Zenerových diod, aby se zabránilo problémům s elektrostatickým výbojem pokaždé, když někdo zapojí nebo odpojí konektory. Dnešní vozidla obvykle obsahují přibližně 200 různých ochranných diod rozložených po různých částech včetně řídicích jednotek motoru, brzdových systémů a všech druhů senzorů. To vytváří vícevrstvou obranu proti elektrickým problémům, což inženýři v oboru automobilového průmyslu pečlivě sledují podle požadavků průmyslového standardu ISO 7637 pro testování komponent.

Zenerovy a TVS diody pro regulaci napětí a ochranu proti elektrostatickému výboji

Zenerovy diody pro účely regulace a omezení napětí

Zenerovy diody svá díla tvoří tím, že ovládají napětí prostřednictvím takzvaného zpětného průrazu. Důvod jejich výborného výkonu spočívá v silně legovaných PN přechodech uvnitř, které umožňují omezení napětí na určitých bodech, jež můžeme poměrně přesně předpovědět. Standardní diody o tuto schopnost neposadí. Pokud inženýři potřebují zajistit hladký provoz zdrojů napětí, obzvláště když dochází k fluktuacím napětí, Zenerovy diody se stávají užitečnými. V podstatě fungují jako pojistné ventily, které propustí přebytečné napětí, jakmile vstup překročí nastavené meze. Tím chrání všechny citlivé komponenty v dalším průběhu před poškozením nadměrným napětím.

Návrh Zenerových omezovacích obvodů pro stabilní výstupní napětí

Dosáhnout dobrého výkonu z obvodů s diodami a odpory závisí hlavně na nalezení správné rovnováhy mezi odpory a diodami, pokud jde o řízení proudu a správné nastavení napěťových úrovní. Proudově omezující rezistor musí umožnit dostatečný zpětný proud, aby obvod mohl správně fungovat i za podmínek průrazu, ale zároveň ne příliš vysoký, aby součástky nezačaly příliš zahřívati. Průmyslové obvody obvykle udržují přesnost kolem 1 %, i když dojde k náhlým změnám zátěže. Při návrhu těchto systémů musí inženýři vypočítat, kolik výkonu se ztratí v různých scénářích, zejména s ohledem na extrémní napěťové situace, které se mohou občas vyskytnout. Pro všechny tyto výpočty existují konkrétní rovnice.

Výkon odporu = (Vmax - Vzener)² / Minimální zátěžový odpor

Kompromisy mezi rozptylem výkonu a přesností regulace

Abychom získali maximum z Zenerových diod, musíme přijmout určité kompromisy mezi regulací tepla a přesností. Když použijeme menší sériové rezistory, pomáhají udržovat lepší regulaci zátěže, protože udržují stabilní proudy v průrazné oblasti. Ale existuje i nevýhoda – tyto malé rezistory způsobují rychle rostoucí ztráty výkonu. Na druhou stranu větší rezistory generují méně tepla, což zní dobře, dokud nezačneme sledovat stabilitu regulace. To se stává skutečným problémem, pokud je zátěž nízká, protože někdy proud procházející Zenerovou diodou prostě nestačí k řádnému provozu. Větší výrobci obvykle doporučují inženýrům, aby snížili výkonové specifikace diod na polovinu, pokud chtějí dlouhodobě spolehlivý provoz. Tato doporučení ukazují, proč je efektivita v této oblasti návrhu elektroniky stále obtížně dosažitelným cílem.

Aplikace ochranných diod (TVS) v konzumní elektronice a ochrana proti elektrostatickému výboji (ESD)

Dioda Transient Voltage Suppression (TVS) poskytuje specializovanou ochranu proti elektrostatickému výboji (ESD), reaguje v nanosekundách a přesouvá přechodné proudy pryč od citlivých obvodů.

| Elektronické systémy | Práh ochrany | Příklady aplikací |

|---|---|---|

| Spotřebitelská zařízení | odolnost proti ESD 8–15 kV | Porty chytrých telefonů, nositelné zařízení |

| Automobilové řídicí jednotky | Přetížení při výpadku zátěže | Systémy infotainment |

| Průmyslové řízení | Hromem indukované napěťové špičky | Moduly PLC komunikace |

Podle studií o spolehlivosti polovodičů, implementace TVS snižují poruchy způsobené ESD o 70 % v exponovaných rozhraních, jako jsou USB-C konektory. Díky nízkým světlovým napětím urychlují odvod energie, než dosáhnou destruktivních mezí přechodná napětí.

Dioda s ultranízkou kapacitou pro zachování integrity rychlých signálů

Pro signálové linky potřebujeme varistorové diody s kapacitou pod 1 pF, pokud chceme udržet data na těchto rychlých více gigabitových rozhraních nedotčená. Starší typy ochranných diod obvykle přinášejí kapacitu vyšší než 3 pF, která způsobuje vážné zkreslení signálu, jakmile rychlost překročí 480 Mbps. Proto jsou moderní diodové pole tak důležitá, protože snižují tyto rušivé kapacitní zátěže na úrovni pF, a přitom stále nabízejí kanálový odpor pod 1 ohm. Tyto vylepšení umožňují ochranu portů Thunderbolt 4 pracujících na rychlosti 40 Gbps, aniž byste se museli bát zkracování pulzů nebo chybovosti bitů. Do budoucna se na trhu objevují nové ochranné integrované obvody s více kanály, které využívají diody s kapacitou 0,5 pF nebo nižší a fungují výborně jak s protokoly USB4, tak HDMI 2.1. Celkem působivá technologie pro každého, kdo se dnes zabývá rychlými digitálními signály.

Pokročilé aplikace diod v rychlých a miniaturizovaných systémech

Ochrana rozhraní s vysokou rychlostí přenosu u USB, HDMI a Thunderbolt

Dioda TVS hraje klíčovou roli při ochraně moderních rychlých datových přenosů, jako jsou USB4, HDMI 2.1 a Thunderbolt 4, před napěťovými špičkami. Problém je v tom, že tato rozhraní pracují s neuvěřitelně vysokou rychlostí měřenou v několika gigabitech za sekundu, takže i nejmenší napěťová špička trvající pouhou část miliardtiny sekundy může zcela narušit přenos dat. Fungování zajišťují právě integrované diodové komponenty, které v podstatě působí jako pojistné ventily pro elektrické přepětí. Zvládnou elektrostatický výboj přesahující 30 kilovoltů, aniž by ovlivnily skutečnou kvalitu signálu. Vezměme si například HDMI 2.1 s jeho obrovskou propustností 48 gigabitů za sekundu. V tomto případě diody TVS začnou fungovat za méně než jednu nanosekundu a přesměrují škodlivé napěťové špičky pryč od citlivých integrovaných obvodů, dříve než by způsobily trvalé poškození.

Výzvy spojené s kapacitou při integraci diod na signálových linkách

Problém s parazitní kapacitou se stává opravdu zřejmým, když se snažíte integrovat ochranné diody do těchto vysokofrekvenčních obvodů, které dnes nacházíme v portech USB-C. Klasické diody obvykle přidávají kapacitu okolo 5 až 10 pF, což narušuje integritu signálu, jakmile frekvence překročí 5 GHz. A to je významný problém zejména pro ty 40Gbps Thunderbolt připojení, která vyžadují čistý přenos dat. Odborníci, kteří tyto návrhy řeší, si ale našli cestu, jak tomu předejít. Obrací se k těmto velmi nízkokapacitním ochranným diodám (TVS) s kapacitou pod 0,3 pF, a zároveň optimalizují vedení spojů na desce plošných spojů. Někteří dokonce experimentují s vícepřechodovými křemíkovými strukturami, které pomáhají potlačit ty nepříjemné impedance způsobené touto nežádoucí kapacitou.

Trend: Miniaturizované diodové pole pro ochranu vícekanálových datových přenosů

Trend komponent 051006 zdůrazňuje rostoucí využívání monolitických diodových polí, která obsahují 8–12 jednotek ochrany TVS v pouzdrech o velikosti 1 mm². Tato řešení v mikroúrovni zajišťují současnou ochranu všech kanálů v rozhraních USB4 nebo DisplayPort. Díky jejich integrovanému návrhu dochází k eliminaci zkreslení kanálů a zároveň se snižuje míra poruch ESD o 63 % ve srovnání s diskrétními diodovými řešeními (průzkum ESDA 2023).

Případová studie: Snížení poruch ESD v portech USB-C pomocí integrovaných diod

Jedna z předních značek notebooků zaznamenala výrazný pokles problémů s ESD na USB-C, když začala používat malé diodové pole ve svých návrzích portů. Nový přístup jim přinesl mnohem lepší výsledky v několika ukazatelích. Kapacita se snížila téměř o 94 %, z 4 pF na pouhých 0,25 pF. Také fyzický prostor potřebný pro ochranu se zmenšil o 40 %, což je velmi důležité v kompaktních zařízeních. Navíc splnilo všechny požadavky na standard IEC 61000-4-2 úrovně 4. Pokud se podíváme na výkon v reálném světě, zhruba 3,2 milionu portů nadále fungovalo správně s méně než 0,1 % poruchovosti během 18 měsíců, i když byly vystaveny událostem ESD o napětí 12 kV během těch nepříjemných situací s horkým připojením, které všichni dobře známe.

Často kladené otázky

Jaké jsou hlavní funkce diod v elektronických obvodech?

Diody primárně fungují jako jednosměrné ventily pro proud, které umožňují jeho průtok v jednom směru a zároveň blokují průtok v opačném směru. Díky tomu jsou nezbytné pro usměrňovací a ochranné funkce.

Jak diody chrání před napěťovými špičkami?

Tyristory diody okamžitě potlačují napěťové špičky a odvádějí škodlivé proudy od citlivé elektroniky, aby se předešlo poškození.

Proč je křemík v mnoha aplikacích upřednostňován před germaniem?

Křemík nabízí lepší odolnost proti vysoké teplotě, kompatibilitu s výrobními procesy a vyšší odolnost proti zpětnému napětí, což ho činí ideálním pro výkonové a digitální aplikace.

Jakou roli hrají Zenerovy diody při regulaci napětí?

Zenerovy diody udržují stabilní výstupní napětí tím, že umožňují průchod přebytečného napětí, jakmile vstupní napětí překročí předem stanovené meze, čímž chrání citlivé komponenty.

Obsah

- Jak diody řídí tok proudu v elektronických obvodech

- Dioda pro ochranu proti přepětí a obrácené polaritě

-

Zenerovy a TVS diody pro regulaci napětí a ochranu proti elektrostatickému výboji

- Zenerovy diody pro účely regulace a omezení napětí

- Návrh Zenerových omezovacích obvodů pro stabilní výstupní napětí

- Kompromisy mezi rozptylem výkonu a přesností regulace

- Aplikace ochranných diod (TVS) v konzumní elektronice a ochrana proti elektrostatickému výboji (ESD)

- Dioda s ultranízkou kapacitou pro zachování integrity rychlých signálů

- Pokročilé aplikace diod v rychlých a miniaturizovaných systémech

- Často kladené otázky