With every new innovation and advancement we take on as a society

it seems like the world as a whole is becoming more digital. A huge factor contributing to this would be the growing importance of smartphones, tablets, and laptops in our day to day lives. With all this in mind, guarding equipment from Electrostatic Discharges (ESD) remains crucial to technology like smartphones and laptops. So, in this article, we will discuss the importance of ESD protection, the various threats associated with it, and the steps that need to be taken by manufacturers to defend fragile machinery parts and components.

We can define Electrostatic Discharge (ESD) as the defined flow of electricity between two charged objects within a certain distance due to a difference in electric potential.

If separated objects can be connected with a discharge, ESD events can happen. To mitigate the risks posed by ESD, steps must be taken to limit the fallout from ESD events and their triggers. ESD Protection refers to activities aimed at minimizing the risk of controlled discharge events which could lead to gradual deterioration or damage to electronic components resulting in a device malfunction or complete failure.

Each industry has its own methods for protecting electronic devices from electrostatic discharges (ESD).

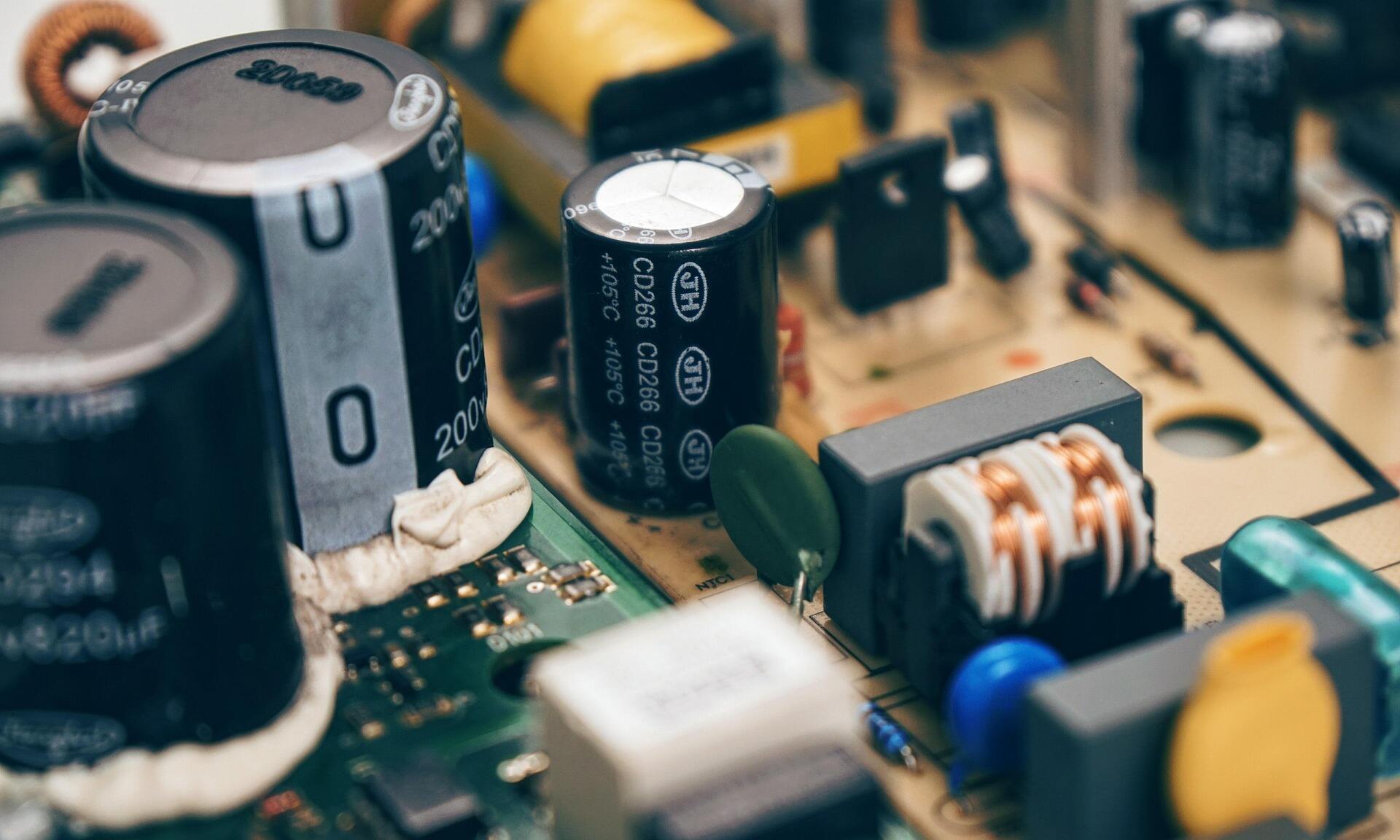

To some extent, the use of ESD protective materials, grounding techniques, or protective components such as TVS diodes, capacitors, and varistors provide some level of protection. ESD protective materials safeguarding electronic devices from static electric discharges works by neutralizing any charge that could be harmful. Grounding dissipates charges while protective components counter voltage spikes caused by ESD discharges.

Telecommunication, automotive, and consumer electronics are the most concerned with ESD protection.

For instance, static discharges can disrupt communication networks in the telecom industry, resulting in expensive outages. In addition, the automotive sector is particularly vulnerable to static discharges due to the risk they pose to electronic control units which oversee critical operations that are essential to the vehicle’s dependability.The need for effective ESD protection increases with component miniaturization, especially with advanced ESD damage technologies. These damages become more likely with the reduction of the device's size and the parts within it growing closer together. Adopting more advanced ESD damage technologies is along the line of needing small but powerful devices. This shift will happen as long as there is a need for small, lightweight, and powerful devices.

All electronics industry stakeholders and consumers must realize the risks associated with ESD.

With shifting focal points in the industry, finding the right solutions will be imperative for an electronic device's preservation and lifetime reliability. Electrostatic discharge impacts can be greatly mitigated when proactive measures are taken, resulting in a much safer and more resilient electronics environment.

Recent technological changes predict a heightened focus on ESD protection

and improvements have already been noted with developments in electrical engineering and materials science. Also, compliance regulations are becoming stricter, mandating ESD protection in the design and manufacturing process. Companies that adopt comprehensive approaches toward ESD will have better differentiation opportunities in the competitive electronics market.

Table of Contents

- With every new innovation and advancement we take on as a society

- We can define Electrostatic Discharge (ESD) as the defined flow of electricity between two charged objects within a certain distance due to a difference in electric potential.

- Each industry has its own methods for protecting electronic devices from electrostatic discharges (ESD).

- Telecommunication, automotive, and consumer electronics are the most concerned with ESD protection.

- All electronics industry stakeholders and consumers must realize the risks associated with ESD.

- Recent technological changes predict a heightened focus on ESD protection