The Unsung Workhorses of Power Conversion

In the intricate ecosystem of modern electronics, few components work as tirelessly or quietly as bridge rectifiers. These compact assemblies, often no larger than a postage stamp, serve as the critical link between the alternating current (AC) that flows through power grids and the direct current (DC) that fuels nearly every electronic device we rely on. From the smartphone on your desk to the industrial robots in factories, bridge rectifiers ensure a steady, reliable power supply, making them indispensable in the digital age. Their ability to convert AC to DC efficiently and consistently has cemented their role as foundational elements in electronics, bridging the gap between raw electrical energy and the precise power needs of sensitive circuits.

The Core Mechanism: How Bridge Rectifiers Work

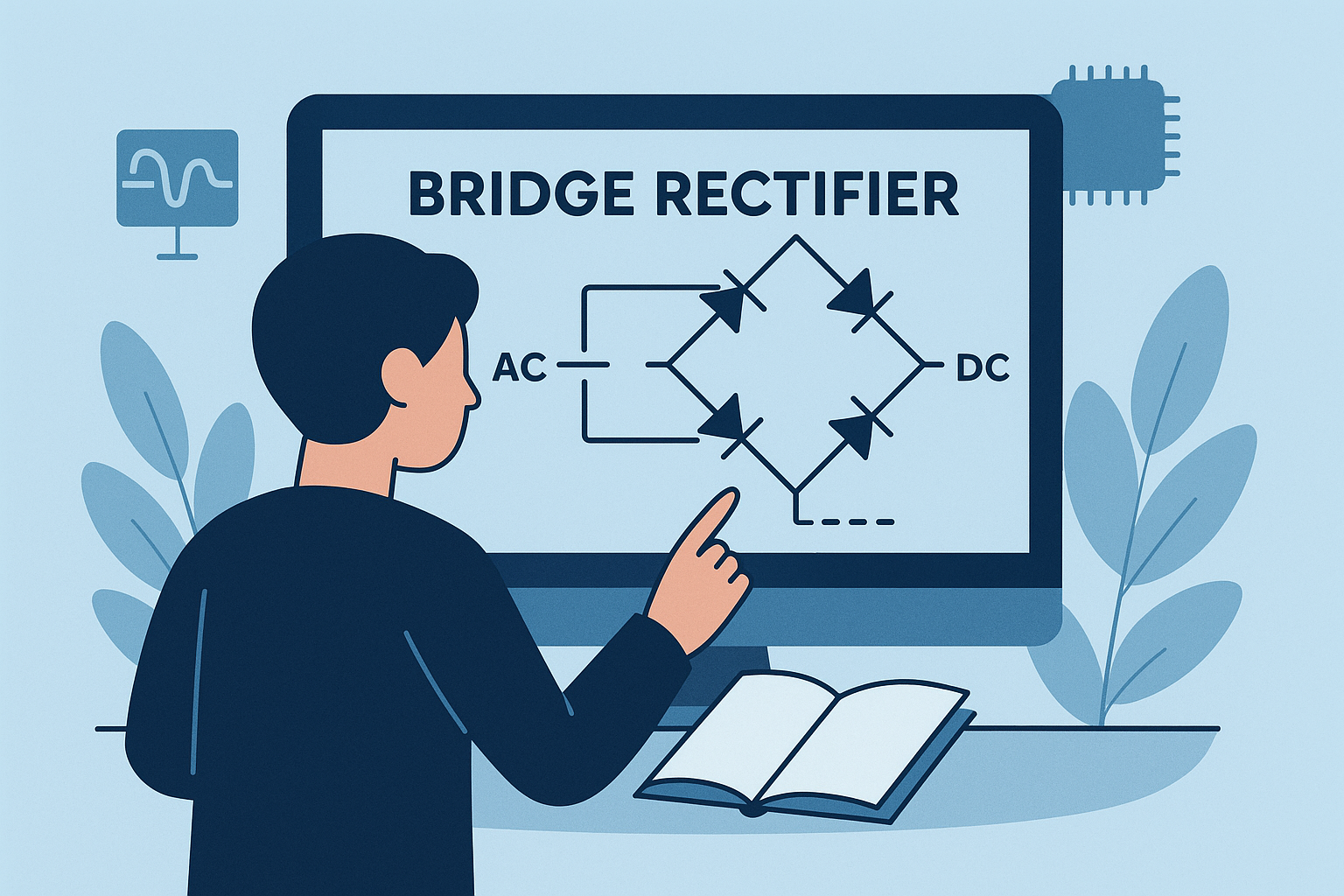

At the heart of a bridge rectifier lies a clever arrangement of four diodes, connected in a diamond-shaped configuration. This design is engineered to solve a fundamental problem: AC power alternates direction 50 or 60 times per second, while most electronics require a unidirectional current to operate. The bridge rectifier’s diode network ensures that regardless of which direction the AC current is flowing, it is redirected to flow in a single direction through the connected device.

During the positive half-cycle of the AC waveform, two diodes in the bridge conduct electricity, creating a path that sends current through the load in one direction. When the AC cycle reverses, the other two diodes activate, redirecting the current to maintain the same direction through the load. This full-wave rectification process produces a pulsating DC output that, while not perfectly smooth, is far more consistent than the half-wave output of a single diode rectifier. To further refine the signal, engineers often pair bridge rectifiers with capacitors, which store electrical energy during peaks and release it during troughs, resulting in a near-constant DC voltage—ideal for powering delicate microchips and sensors.

Key Advantages Over Other Rectification Methods

Bridge rectifiers outshine simpler rectification solutions in several key areas. Unlike half-wave rectifiers, which only use half of the AC waveform and waste significant energy, bridge rectifiers utilize the entire AC cycle, doubling the efficiency of power conversion. This makes them far more suitable for high-power applications where energy waste is costly or impractical.

Another advantage is their ability to operate without a center-tapped transformer, a component required by some full-wave rectifier designs. By eliminating the need for this bulky part, bridge rectifiers reduce the size and weight of power supplies— a critical benefit in portable electronics like laptops and tablets. Additionally, their symmetric design minimizes voltage fluctuations, protecting sensitive components from harmful power spikes and ensuring stable performance over time.

Applications in Consumer Electronics

Consumer devices are perhaps the most visible domain where bridge rectifiers excel. Every time you plug in a phone charger, laptop adapter, or gaming console, a bridge rectifier is hard at work. In smartphone chargers, for example, the rectifier converts the 120V or 240V AC from the wall into low-voltage DC (typically 5V or 9V) that safely charges the device’s battery. Without this conversion, the high-voltage AC would damage the phone’s delicate circuitry.

Similarly, home appliances like microwave ovens, refrigerators, and smart TVs rely on bridge rectifiers to power their control systems. In these devices, the rectifier ensures that microprocessors, sensors, and digital displays receive a steady DC supply, enabling precise temperature regulation, timer functions, and user interface interactions. Even small gadgets like electric toothbrushes and wireless earbud chargers use miniaturized bridge rectifiers to convert AC power into the low-voltage DC needed for their rechargeable batteries.

Industrial and Renewable Energy Applications

Beyond consumer goods, bridge rectifiers play pivotal roles in industrial and renewable energy systems. In manufacturing, they are integral to power supplies for motor drives, robotics, and automated machinery. These systems often require high currents and stable DC voltages to operate precision motors and sensors, and bridge rectifiers deliver this reliably, even in harsh factory environments.

Renewable energy systems, particularly solar and wind setups, depend heavily on bridge rectifiers to maximize energy harvest. Solar panels generate direct current, but this current is often variable due to changes in sunlight intensity. Bridge rectifiers, paired with inverters, help stabilize this output, converting it into usable AC power for homes or feeding it into the grid. In wind turbines, which generate AC power that fluctuates with wind speed, bridge rectifiers convert this variable AC into DC for storage in batteries or for conversion back to stable grid-compatible AC. This process ensures that renewable energy sources can integrate smoothly with existing power infrastructure, reducing reliance on fossil fuels.

Automotive and Transportation Uses

Modern vehicles, whether gasoline-powered, hybrid, or electric, are rolling examples of advanced electronics— and bridge rectifiers are key components in their electrical systems. In traditional cars, alternators generate AC power to charge the battery and power accessories like lights and infotainment systems. Bridge rectifiers convert this AC output into DC, ensuring the battery charges efficiently and sensitive electronics receive stable power.

In electric vehicles (EVs), the role of bridge rectifiers becomes even more critical. EVs rely on high-voltage battery packs that require precise charging and discharging. Bridge rectifiers in EV charging systems convert AC power from charging stations into DC to replenish the battery, while also regulating power flow between the battery and the vehicle’s motors. Their efficiency directly impacts charging speed and driving range, making them a focus of innovation in the push for more sustainable transportation.

Innovations Shaping the Future of Bridge Rectifiers

As electronics continue to evolve, so too do bridge rectifiers. Engineers are developing new designs using advanced materials like silicon carbide (SiC) and gallium nitride (GaN), which offer higher efficiency and better heat resistance than traditional silicon diodes. These materials allow rectifiers to operate at higher temperatures and voltages, making them suitable for next-generation power systems in electric vehicles, renewable energy grids, and industrial equipment.

Miniaturization is another key trend. Modern bridge rectifiers are being integrated into compact surface-mount packages, reducing the size of power supplies and enabling sleeker device designs. Additionally, smart rectifiers with built-in protection features— such as overcurrent and overvoltage safeguards— are emerging, enhancing reliability in critical applications like medical devices and aerospace systems.

Conclusion: A Foundation for Modern Electronics

Bridge rectifiers may not grab headlines, but their impact on modern life is undeniable. By converting AC to DC efficiently and reliably, they enable the operation of everything from smartphones to solar farms. As technology advances, their role will only grow, with new materials and designs pushing the boundaries of efficiency, size, and performance. In a world increasingly dependent on electronics, bridge rectifiers remain essential, quietly powering progress one conversion at a time.

Table of Contents

- The Unsung Workhorses of Power Conversion

- The Core Mechanism: How Bridge Rectifiers Work

- Key Advantages Over Other Rectification Methods

- Applications in Consumer Electronics

- Industrial and Renewable Energy Applications

- Automotive and Transportation Uses

- Innovations Shaping the Future of Bridge Rectifiers

- Conclusion: A Foundation for Modern Electronics