Explore 1.85 mm RF coaxial connectors offering 67 GHz bandwidth, low VSWR, and stainless-steel precision. Perfect for mmWave test equipment, 5G systems, and aerospace applications.

Pushing the Boundaries of Frequency

At frequencies where every fraction of a decibel counts, precision is no longer optional — it’s essential. The 1.85 mm RF coaxial connector series was developed to operate reliably up to 67 GHz, setting a new benchmark for millimeter-wave testing, high-speed data transmission, and advanced communication design.

Built for laboratories, radar systems, and 5G mmWave platforms, these connectors combine microscopic mechanical accuracy with exceptional electrical performance. They are the invisible bridge that keeps the world’s most advanced signals flowing cleanly.

The Evolution of Precision RF Design

Derived from the proven 2.4 mm and 2.92 mm (K) connector families, the 1.85 mm connector takes miniaturization and frequency capability a step further — achieving a perfect 50 Ω impedance and maintaining low VSWR across the entire 67 GHz band.

Its air-dielectric structure, robust stainless-steel body, and gold-plated beryllium-copper contacts ensure consistent performance even under extreme vibration or temperature change. This precision makes it the connector of choice for vector network analyzers (VNAs), mmWave test fixtures, and high-band 5G RF modules.

Designed for Accuracy and Stability

The 1.85 mm RF connector offers superior repeatability in both electrical and mechanical dimensions. Each component is manufactured with sub-micron tolerances to maintain alignment between the center conductor and outer shell.

Frequency Range: DC – 67 GHz

Impedance: 50 Ω

VSWR: ≤ 1.15:1 typical

Coupling Mechanism: Threaded interface, precision torque repeatability

Materials: Stainless steel body, air dielectric, gold-plated contacts

Temperature Range: –55 °C to +165 °C

Compliance: RoHS and REACH certified

These parameters allow low insertion loss and high return loss, guaranteeing consistent phase performance in measurement and signal chains.

Where Innovation Meets Measurement

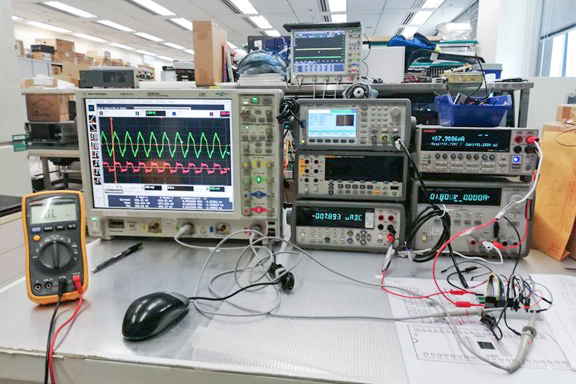

In high-frequency design labs, 1.85 mm connectors are more than hardware — they are measurement references. Their excellent VSWR and phase stability make them standard interfaces for 67 GHz VNAs, oscilloscopes, and spectrum analyzers.

Engineers depend on them when testing mmWave antennas, phased-array radar modules, or 5G transceivers operating in the 26–67 GHz range. In such environments, even a slight mismatch can compromise calibration — which is why the 1.85 mm precision connector is trusted across industries that demand absolute accuracy.

Performance in Real-World Applications

5G mmWave Networks: Stable, high-frequency interconnects for base station and device testing

Radar & Defense Systems: Rugged connectors with low signal reflection under vibration

Microwave Instrumentation: Reliable calibration ports for 67 GHz analyzers and synthesizers

High-Speed Data Links: Low-loss interfaces for optical and wireless backhaul systems

Aerospace RF Platforms: High-stability interconnects for mission-critical mmWave communication

Where precision meets performance, 1.85 mm connectors define the connection standard.

The New Benchmark for Millimeter-Wave Engineering

As communication and sensing systems evolve toward terahertz-class frequencies, the 1.85 mm connector remains one of the most accurate and durable solutions for millimeter-wave engineering. Its design allows for consistent calibration repeatability, rugged torque endurance, and low reflection coefficients — critical for emerging 5G, 6G, and automotive radar technologies.

Unlike lower-frequency connectors, every 1.85 mm interface is a mechanical masterpiece — capable of sustaining precise electrical contact under repeated mating cycles without deformation.

For RF engineers, it represents the confidence to measure, design, and innovate at frequencies once considered unreachable.

Supply, Customization & Quality Commitment

We provide a complete range of 1.85 mm RF coaxial connectors, including male, female, adapter, flange-mount, and cable-mount versions. Each connector undergoes 100% VSWR, insertion loss, and phase-stability testing.

Our manufacturing process follows ISO-certified quality control, with RoHS/REACH-compliant materials and traceable batch calibration data. We also support stock sourcing, BOM kitting, short lead times, and global logistics, ensuring reliable delivery for OEM, ODM, and R&D customers.

Whether for a single calibration port or an entire microwave system, we deliver the precision that enables performance.